Everything posted by Mopar1973Man

-

Down pipe or firewall?

After doing injectors and head studs for @Sycostang67 I seen how close the his exhaust pipe is to the firewall. Part of it is he opted for true 4 inch pipe. Not like typically 3 to 4 kits.

-

How long do you think the used truck market for good 24 v 5.9 Cummins 2 nd gens will hold out ?

I just found my old window sticker and just thinking how good the Dodge Cummins held it price. At the same time I'm watching the parts market and there is shortages on common parts and some parts are going up in price too for our trucks.

-

Dana 80 pinion seal leak

That's why I was asking about learning here. I really trust you guys for info but randomly watching YouTube can be risky like watching a YouTube about tightening a 5th gear nut with chisel and hammer. I know that information is incorrect and will not work at all. That way all you can confirm info and then we all learn together with correct info. Once the forum thread is gathered up info the create an article for everyone.

-

Brake Light Switch..."DO NOT REINTSALL"

Like I mention you can pull the pin out carefully it will ratchet out. But be careful this can't be done too many times. Brake light switch is pretty cheap.

-

Dana 80 pinion seal leak

I'd love to learn for sure. Only thing I've done is lube changes. Never had an axle fail yet in all my years. Love reading all this just wish I could see how it was done. All the stuff about backlash and heel toe settings I'm not sure on.

-

Dana 80 pinion seal leak

I wish I could watch one of you doing all this then understand better. Yup never done any gear work ever.

-

DUALLY SIDE ID LIGHTS

Wiring map...

-

Dana 80 pinion seal leak

Yeah but I've got no clue how to set all that up. How to torque it etc. Last article here mentions torque on the pinion nut being quite high and needing a torque multiplier. I know the article is gone but I never done any axle work before. I've always had shops do the repair. If you have the knowledge on this it would be great to have an new article made...

-

Dana 80 pinion seal leak

That is something I would love to learn someday. Never done any axle work ever.

-

Boost Dropping to Zero on Quad

Sounds like you need to do a W-T ground mod.

-

How long do you think the used truck market for good 24 v 5.9 Cummins 2 nd gens will hold out ?

I would rather crawl under my 2002 Dodge any day over any Common Rail. More expensive and bigger pain in ... Everyone tends to forget I work thousands of vehicles, Ford, Chevy, Dodge and plenty of rice too.

-

How long do you think the used truck market for good 24 v 5.9 Cummins 2 nd gens will hold out ?

Exactly what I see people selling there 3rd, 4th or 5th gen trucks and wanting a 2nd gen. There is a high demand for 2nd gen trucks here.

-

Honda Tri Fuel.

Secret... I've been using a 6500w Harbor Frieght generator. It fairly quiet, has 240 but I only use the 120V for the inverter. Inverter only allows clean power. Frequency has to be really close to 60 Hz. Other than that it drops the generator because it's dirty power. Voltage as well has to be between a range I set. 130V upper and no lower than 115V again out of range the generator is dropped. Even better yet my inverter is old. It a old modified sine-wave. Never had any electronic failure from dirty power. Computers, TV, cellphones, tablet, any thing it will not be damaged. So me I don't have to have at Honda Invertered Generator I can save money use a cheap harbor freight no issues.

-

Honda Tri Fuel.

Nope. Already got 240V generator. But my system is all 120V except the well pump which uses a step up transformer.

-

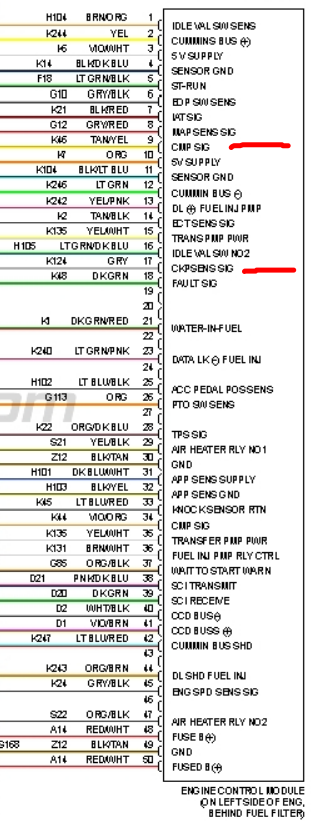

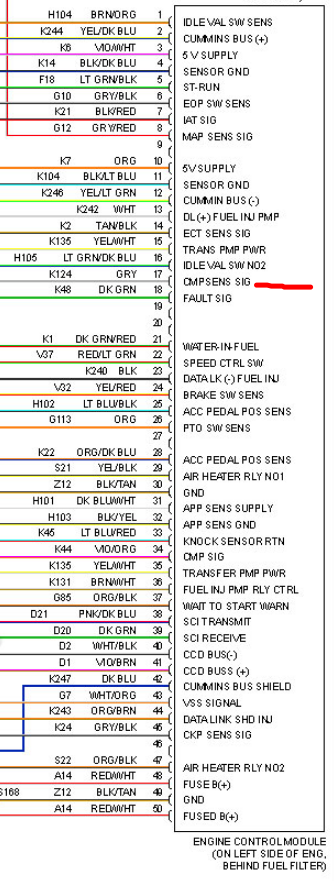

Motor swap 02 pickup with 98.5 motor

Basically its just best to have all the 2002 stuff. Engine loom, ECM and PCM, then change the cam and gear, then the gear case too. Then everything works totally normally. All the wiring is right. There is differences between ECM and PCM then there might be other weird issues. 98.5 to 2000 is a single tooth cam gear just for TDC marker that is all. Take note that the single tooth is on the outer gear rim. Now look at later series... The tone wheel is inside the rim hence why the gear case change... The crank sensor was later relocated from the crank to the cam and the old cam sensor done away with (clear as mud I know). You would have to look at wiring maps and you'll see the crank wiring was relocated to the cam, the the old cam sensor is not connected in the ECM plug any more. Hence its just best to have the full wiring loom. Again because of software differences PCM might not talk to the newer ECM because of communication differences and how data is sent. This is why its best to have both the ECM and PCM now reflashed for the newer software and matching this will reduce communication errors and issues. Now 98.5 to 2000... ECM plug. Now 2000 to 2002 ECM plug... Take notice that the old Cam Sensor lead is open now and no longer used but the crank sense is renamed to Cam sensor but its still wired to the Crank sensor pin in the ECM. Pin 9 has no wire...

-

Honda Tri Fuel.

I started out with generators. Then converter to full solar power and hydro power. Silent power that requires no fuel and always ready. As soon as the inverter senses dirty power it drops the city power and switches to the inverter in under 200ms. Might see a blink in the house but everything is still running. Just had the inverter fire up 4 days ago my computer screen went black for a second or so the came back just where I left off. Future plan is to take my 6500 watt generator wired into the inverter so if the load exceeds the 4000 watt inverter so it would start and warm up then pair the AC wave presto you now have 10500 watts of power total. For the last 20 years I've just ran the inverter solo typically.

-

What does Cummins /Dodge recommend for anti gel in the new trucks ?

No. You can use and product you wish. Like the Optilube was developed at the same time I was doing 2 cycle oil studies. The Optilube is the best product for lubricity and antigel features. Being the test was done at the same time. Hence why I have all this data.

-

Adrenaline will not initialize

Exactly I don't want anything in my cab that even hints at even having a tuner hence why I love Quadzilla there is no need to have a display. I run headless most days and other are clueless because there is no display. Guys with Smarty Touch or Edge Performance tuner have a higher chance of the vehicle broken into or stolen. Being there is no signs of a display in my truck so likely going to be hit. Plus stock wheels and 245s no reason to mess with a stock truck. Little do they know...

-

Adrenaline will not initialize

-

Adrenaline will not initialize

Did the mod myself. I cut the plug off the Quad harness and extended the 4 wires equally to the cab. All solered and shrink tubed..Then plugged in the iQuad head right inside the cab.

-

Motor swap 02 pickup with 98.5 motor

The biggest problem is the crank / cam sensors from early to converting to later with cam only sensor. The gear case is wrong because the sensor location and the tone wheel on the cam is wrong. This forces you to change the cam and gear housing for proper operation. Other that that your engine will be in limp mode constantly. There is only 1 notch in the cam and this will display as a extremely low RPM and doesn't match up with the VP44 (P1690 code). Once you change the cam the tone ring will be correct but the gear case has to change too because the location of the tone ring is in a different position. Hence why these parts need changing.

-

Adrenaline will not initialize

Since I relocated my Bluetooth head into the cab tuck under the cup holder on the floor. I've never had a radio issue ever. Even with the new Quadzilla head that does both Bluetooth and WiFI both still never had one issue. Never had a import or export problem. Since relocation of the head I've never had another connection problem. Now the most phone calls I get is for iPhone (apple) and iTablets (apple) that will not import iQuad tune files or connect or reliably. Just have a call last week for guy that struggling with iPhone not importing a downloaded tune from M73M download area.

-

What does Cummins /Dodge recommend for anti gel in the new trucks ?

Boy that crazy and it already been proven time and time again PS isn't a good additive. Then the other under handed is the there is part that are not part of thew warranty because of being a wearable item. I'll grab my buddy that has the list and I'll repost it here. Like him he was a Common Rail owner at one time and got rid of it. Too many things the dealer didn't cover. Even using Bosch own documents... You would way better off with Opti-Lube XPD... It scored a 317 HFRR way less wear! Compared to Power Service that score 575 HFRR very very damaging... What your CP3 will look like... This is Bosch own testing of fuel lubricity. https://opti-lube.com/opti-lube-xpd-all-in-one-diesel-fuel-additive-1-gallon-without-accessories-treats-up-to-512-gallons/ Now 317 HFRR is going to be much better... So research your products just because Cummins or Dodge says it good you better still do you own study because Power Service has been poor rated for YEARS. Only gains +65 HFRR. Where OptiLube XPD will gain +319 HFRR. This has lubricant in the bottle for sure.

-

How long do you think the used truck market for good 24 v 5.9 Cummins 2 nd gens will hold out ?

Stop all these forest fire that are making more CO2 that any vehicle in the world. Heck just consider a Boeing 747 hold 63,500 gallons of Jet-A fuel and burns just about 5 GALLONS OF JET-A EVERY ONE MILE. So tell a you Govt not to fly and start walking. You know they will still fly. Out here people are getting 20k to 25k for 1998.5 to 2002 Dodge Cummins. No joke.

-

What does Cummins /Dodge recommend for anti gel in the new trucks ?

Be careful alot of anti-gels are worse off than just the diesel fuel itself. Like Power adds a bit more HFRR score. Normal diesel fuel is 520 HFRR. But Bosch wants <460 HFRR. Like myself I don't use any anti gel products at all. Higher cetane just reduces the MPG deeper. Never gelled the Beast in 19 winters and temps as low as -40F. Why? When I last did my study in local fuels the could have already have 50 cetane adding more is just going to reduce power and MPG. Pour point is already good to -20 to -30F. So why waste the money on a product that is not going to do any good for the fuel system taking away lubricity, then taking away BTU content, for fuel that is already treated and does require any help. Oh yeah a bit of science for Power Service. If the product truly has lubricant in the product leave a small sample exposed to the air. It will dry out and be a gummy tar. There is no oil in the product. Any oil will remain after evaporating all the alcohols off for the cetane boosters. Try it with 2 cycle oil. Never changes. Oil will remain oil even exposed to air but sure shows off the alcohol amounts used for cetane boosters.