Everything posted by Mopar1973Man

-

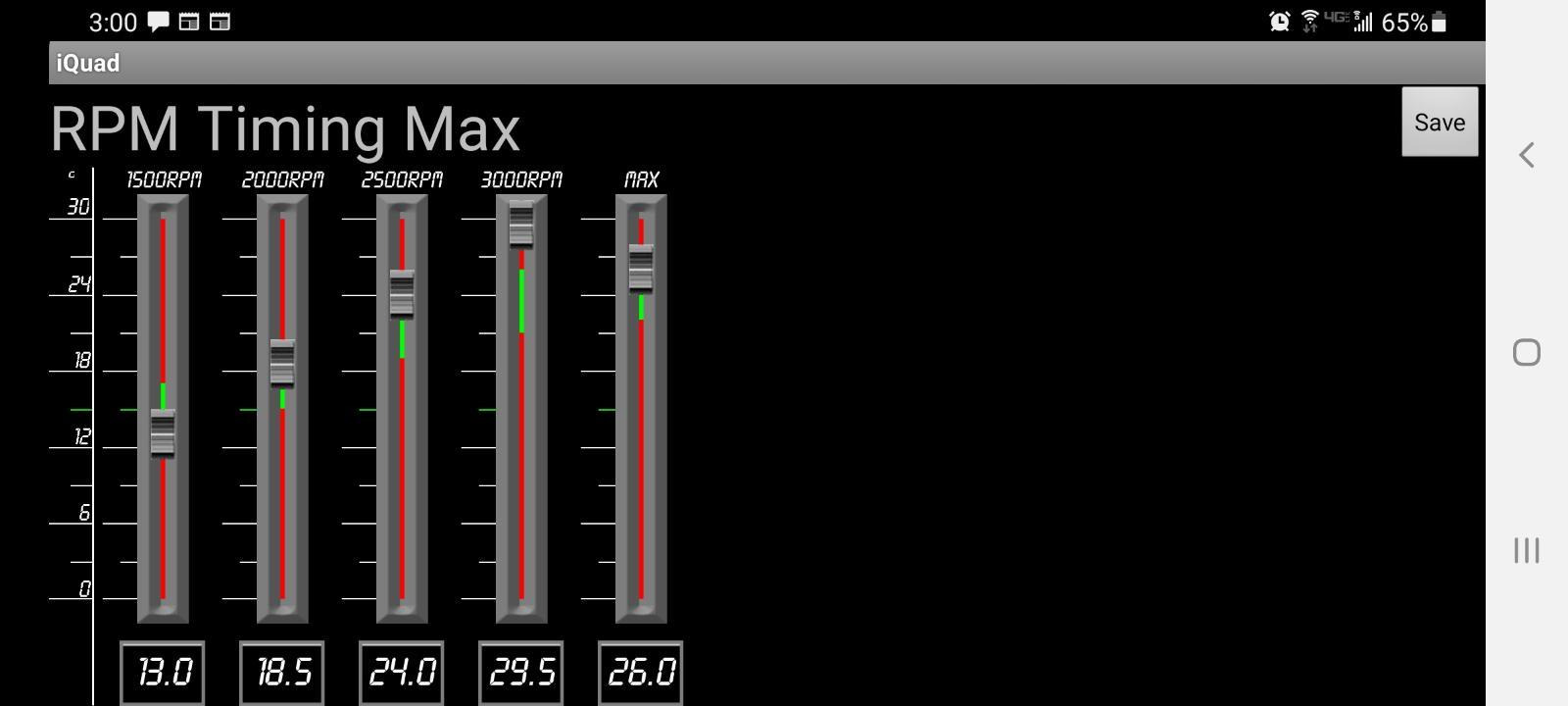

Degree wheel VP44

Might be a bit slow launching though... Too much advancement?

-

Degree wheel VP44

Still a max of 30 degrees but more sliders to allow for timing up to 4k. The 30 degree limit is a mechanical limit of the pump period.

-

2007.5 Dodge Cummins 4x4 ST pickup

You might need to have the ECM reflashed if the software isn't present for cruise control. You might contact a Dodge dealer and ask by VIN number if the ECM has the software present.

-

2001 Ecm Problems

Call them and ask. What you got to lose...

-

2001 Ecm Problems

Nope... The ECM crapped the bed for sure with the P0606. All other error code are result of the P0606 code. There is a solder connection or chip malfunction. Double check your AC noise from the alternator. I know you done the WT ground mod but double check your connection too.

-

Degree wheel VP44

Now I can provide this. The max timing a Quadzilla will provide is 30 degree BTDC. The lowest could possibly be about TDC. Just remember there is 3 parts to the PSG. Fueling, Timing, and Diagnostics. (Error codes, etc.)

-

P0122 Low Votage to APPS

WT ground wire mod is quick about an hour job to split the loom open and mkae the new connections. You just need the crimps for the wire and then a 150A circuit breaker or fuse for the alternator charge lead. I've done three trucks now, my 2002 Beast has this mod too.

-

2019 Ram 2500 vibrates, a lot...

I would think if there is a bent shaft of any type shortly there should be oil leaking through the seals. It will in a short order beat the seals out.

-

Oil leaking out the draft tube

Compression test will show the bad cylinder much quicker. We had a old member with a cracked piston that would pass the blow by test but as the truck warmed up the misfire would get worse. He never did a compression test but ended up replacing the entire engine over a cracked piston.

-

Starter quit!

I had one that I rebuilt the ECM and it ran for 5 miles and then died after the 5 mile run. Sent in back to be tested and it returned good. Reinstalled and 30 second later died again and wouldn't start again. Wiring malfunction in the CANBus is all I can figure. Being all the power functions are through the TIPM. On my 2006 the starter quit too. The exhaust brake is wired in on the same circuit with the starter. Once I blew the fuse in the TIPM for that circuit it dodn't start but once I replaced the fuse it came back with the exhaust brake. (BD Exhaust brake with auto cruise control braking).

-

High IAT, Low Power, Low Boost

Did you check the wire between the IAT sensor and the ECM? If there is a wiring issue say the common sensor ground being bad it can and will alter the IAT signal. TIP: If the IAT is disconnect it will max out the temp at 240*F. So weak connection will cause the value to be high. This is because the +5V signal and sense is on the same wire and requires the ground to pull it back down. If the sensor shorts to ground it will show -40*F. Your case is a bad sensor ground or bad ECM ground. TIP: Do the WT ground wire mod this will ensure the ground to the ECM ground and sensor grounds are good.

-

Defective Head Gasket

Really simple. Like I've said all a long that just because it says Cummins does NOT make it quality. Cummins been and always will change providers when they an make a better dollar. I've already proven the Cummins thermostat and now the Cummins head gasket. All mine are Cummins OE gaskets but different numbers. Same application but superseded. By different manufactures. NOTE: I'm not placing any of this on the vendor. This is strictly manufacture design problem and again by Cummins. If I got to do head gasket again I will NOT be ordering a Cummins gasket... I'll go to NAPA for a head gasket kit. At least with NAPA the upgrade to better products as they go along.

-

Killer dowl pin questions

There was only ONE 2001 Dodge I know of with a KDP problem that was documented by the dealer. Other than that it should of been resolved in 2000.

-

2019 Ram 2500 vibrates, a lot...

Wheel bearings? Loose bearings can allow for wobble of the wheels. Check even the rears. Ball joints or tie rod ends again can allow for movement. This might show up in the steering wheel. Deformed tires, broken belts, etc. I know you said you swapped tires.

-

Cetane do you use it ?

Between bio diesel and 2 cycle oil I've seen most VP44's make at least 250k miles.

-

My first explosive tire failure!

One day I'll get smart and keep a jack on the truck but I need to buy just a bottle jack for the tool box. Floor jack is just too big and too easy to steal out of the bed of the truck.

-

Cetane do you use it ?

I tend to avoid bio in the winter. Bio tends to gel quicker and tougher to un-gel.

-

Defective Head Gasket

My answer is NO. Being Cummins does not produce head gaskets. After seeing this failure I would absolutely say no. Cummins head gasket is produced by BLK (Not Cummins). Both gaskets are Cummins OE, but again not produced by Cummins. The defective gasket... Look the amount of de-lamination. This pic is where the coolant passage blew out. That whole corner gave up and the composite material lifted. Now my old head gasket before when the oil was blowing out the front. The one on the left as you can see did not seperate and still intact. Compared to the right which is also a Cummins OE gasket.

-

My first explosive tire failure!

Well I made my trip down with The Beast and got my 17 wheels and center caps. I've got a appointment in Riggins, ID by 12 noon to have my new 265/70 R17 installed. I got the Hankook ATm's. At least Thor will be ready for this winter with fresh rubber.

-

*Do Not Buy from CPP Diesel*

I'll see about getting some time this weekend and get started building this database of vendors.

-

Cetane do you use it ?

PPD (Pour Point Depressants). The snowmobile 2 cycle oil sold up here had more PPD added to keep the oil liquid till -50*F. So now take the local fuel of -20*F Pour Point and add more oil on top that has -50*F Pour Point it will inch the pour point of the diesel down (how much I'm not sure). The second part is I kept my stock fuel filter which absorbs heat from the manifold. My winter time fuel temp doesn't drop below +20*F ever. So I have ZERO need for any anti-gel products and in 19 years and 432k miles I've never use any anti-gel or had any gelling problems ever! Typical winter in New Meadows can range from -20*F to -40*F.

-

My first explosive tire failure!

I'm glad I was driving slower and on a straight away when it blew out. Just a sudden BOOM! dropped to the ground drop the throttle and let it unwind to about 10 to 15 MPH limp the road side and whip into the storage units there in New Meadows, ID. But yeah that was my FIRST tire blow out in all the miles of driving trucks and cars.

-

My first explosive tire failure!

Well I've been busy doing a side job with my crew. This property is owned by one of my crew. He's got a bunch of old cars we've been moving and clearing the land after his house fire. Well after long day I unhitched from my boss'es goose neck trailer (Big Tex dump bed) which we thought we would use for moving small material. When I left I had to travel over to the dirt track we were using and back out to the main road. In that little bit of time I must of picked up a roll of barbed wire. Windows were rolled up and A/C on. I never heard a single thing. BOOM! I'm made it about 40 miles before it blew the tire... Yup a massive hair ball of barbed wire. The only thing I didn't have on the truck was a jack. I had to call a buddy near home to come out and bring a jack out for me. After getting the tire off I was faced with this and got my dike's out and kept cutting the wire off. I was super lucky my brake line is not damaged at all. Once I got it all cut free I was able to kick the wad with my boot and it fell off. Yup... The bard wire ate the inside wall of the tire blowing it out. This is my FIRST explosive tire failure in my life. After driving 35 years! I'm forced now to go to Parma, ID today and go get my 17 wheels I made a deal with my buddy down there for the set of 4 steel wheels with center caps. Then later on this morning call my other buddy at Chevron have him order my Hankook ATm's for Thor. I'm going back to stock 265/70 R17.

-

Oil leaking out the draft tube

Do a compression test would work too. I'm not a fan of blow by test being it is possible to have only one cylinder with issues and pass.

-

Defective Head Gasket

Yeah I know I've got the two gasket down in the shop yet for that reason. Just been super busy. I promise to post up some pics.