Everything posted by Mopar1973Man

-

Summer time heat

Never thought there would be any savings between free spin hub for the price.

-

*Do Not Buy from CPP Diesel*

Might be a time to create a write up of quality dealers for parts. Me personally I use... Diesel Auto Power - https://www.dieselautopower.com/ RockAuto - https://www.rockauto.com/ Vulcan Performance - http://www.vulcanperformance.com/ NAPA (McCall, ID)

-

Suggestions for injectors, turbo, head gasket.

@Me78569 had a VGT retro fit on his truck. Worked super good.

-

Rv/Solar install

Just don't mount the panels to the roof of the RV. If you park the RV in the shade the solar won't work. Best to have the panels free standing and not on the roof. I've got my panels as free standing and I can chase the sun with the panels but the RV can be parked in the shade.

-

Replacing head gasket

Most likely head curl. If you have stock head bolts the bolts will stretch and mine started coolant at the rear passenger side of the head. Make sure to have the head machined true flat again.

-

Truck randomly dies. Please help, pulling my hair out, and loosing sleep!

I've got lights too but don't even draw a full 10A for all of the lights. Look toward energy efficiency. Still in all a massive 270A alternator is going to draw down more horsepower. I'd rather reduce loads than adding bigger alternator.

-

Need help diagnosing morimoto HIDs not working

Nothing being if the bulb is good should be consumed by the bulb.

-

Thinking about getting a 3rd gen.

As far as I know the regen will still occur but much much less... EGR is turned off and not used. No codes will be thrown.

-

Truck randomly dies. Please help, pulling my hair out, and loosing sleep!

Upgraded alternator not needed. Just need to do the W-T ground wire mod to make things right with AC noise.

-

Oil drip on Driver's side (problem?)

I've got vacuum pump kits on the store. Easy to do and maybe an hour of work. Even got a article on how to do it.

-

Replacing head gasket

There is lots of tiny freeze plugs in the head at the corners. Rotten freeze plugs are only caused by one thing. Bad coolant and lack of changes. To this day my freeze plugs look new and not even rusty looking inside or out at 432k miles and counting on the 2nd Gen.

-

Create Quadzilla V2 Tune With Low End Response/ Torque Management Reduction Like Smarty S03

Timing to too advanced.... 1500 - 13 2000 - 17 2500 - 21 3000 - 25 MAX is not what you think it is. You can control the maximum cruise timing with max. Like I typically set it down a bit lower to kick the cruise timing out by about 2,000 to 2,500 RPM so if you reduce that you can force cruise timing to cancel and jump back into the performance timing. This is a good launch timing. 13 degrees with take another retard when the low boost timing rolls in it could pull down to about 10 degree on a heavy pedal. Retard pushes more fire out towards the turbine and spools the turbo up easy. Starting at 15 degrees there isn't enough retard to spool so it now launches with low power. Quick power need a quick deep retard of timing, spool up get up on boost now switch to performance timing being above that you pull more torque around 2000 so now you get up to speed you can drop +3 degrees for cruise timing at 2k and that will be 20 degrees of cruise timing. Fuel curve is setup to be smoke free but since I got quick spool up the defuel side is just for smoke but once I'm performance timing it will continue to build to the 15 PSI and now both the CanBus and wiretap build together making some serious power. Where like most they ramp up from the bottom which now the CanBus and WireTap are at different stages of power. Best to ramp together for the most power but not from 5 PSI... Not good...

-

2005 Dodge Ram on 35 inch tires being set up RIGHT!

He's been through 3 steering boxes in under 100k miles. Always leaking out the output shaft. The brace takes up the beating that normally the output seal and bearing take. Once I've install that brace not heard a word from him again.

-

Do Not Order anything from ELC Hardware.......Scammers

I'm more picky about brand names that I order and also picking about who I order from. Like for example I had my 1977 Ford Project up there with Neil. Several things I had to get from outside companies like Tail lights, front marker lights, side marker lights, and four bulb sockets. I've found several eBay pages and typically skip the used junk prices. Then I found a Ford Bronco site that had the tails, front and side markers. Bad part is there was two listing with or without reflector for the rears. No phone number. No way to just order the pieces I needed. I ended up reordering the rear tails from RockAuto and then found a better deal on the bulb sockets for the front and rear. Some times its better to stick with what you know than trying to get the best price.

-

2006 Dodge 3500 - MPG

Well S__t! That means all my fuel logs are junk. All my travels are next to a river. Big Salmon River, Little Salmon River, Snake River, Weiser River, Payette River. Come to think about it there isn't much highways out here without a river closely following by.

-

Need help diagnosing morimoto HIDs not working

Best I can say is use a test light and see where the power stops. Just remember the ballast creates a nice 70 to 90 volts.

-

2006 Dodge 3500 - MPG

Same here from Donnelly ID to Home by Pinehurst.

-

Does the adrenaline affect the e c m

Quadzilla Adrenaline does not flash anything to the ECM. Like @Dieselfuturemention above that it just modifies the ECM signal and send the modified info as a priority message. Now if you build a good tune it will be pretty much smokeless and even better MPG and performance than factory tune could. You would have to either HIDE the Quadzilla completely or just remove it before going for smog testing. Yes your completely safe with the Quadzilla. It does not flash any code or alter any software on the ECM.

-

Thinking about getting a 3rd gen.

Two methods of deletes. Physical deletes of the emissions Software delete of the emissions When you do the software method nothing is removed from the truck so it visually passes the inspection. Software is turned off to all the emissions systems. It will still regen but much much less. I will not suggest any physical deletes because of the amount of equipment that is removed and will not pass a visual inspection. I've done it both way now and software method is the fastest and easiest to do just need to flash the ECM with a delete tune. If for any reason you need to return to OEM stock tune the tuner will flash it all back to functional. All the emission system will be back on line. Takes less than 15 minutes to do.

-

Create Quadzilla V2 Tune With Low End Response/ Torque Management Reduction Like Smarty S03

One of the few reasons I've never been a big Smarty fan being that their tune is basically starting the CanBus fuel way above 100% which a good clean tune should not start that high. I might start out lower but once I meet my power point which is set for 15 PSI. This is where my CanBus and wiretap meet together and ramp up together its a rather wicked power. 80% to 100% to 5 PSI 100% from 5 PSI to 15 PSI Stock ECM fuel 100% to 150% from 15 PSI up to +30 PSI. Then I set the Wire tap to start at 15 PSI and run all the way to 40 PSI. The other half is make sure your 1,500 RPM band starts at 13 degree. Then you want a good health drop in timing. It will spool very rapid. More retard the quicker to spool this is due to putting more of the expanding gases in the exhaust manifold.

-

Truck randomly dies. Please help, pulling my hair out, and loosing sleep!

Timbos APPS uses mechanical means to set the IVS switches. Then the rest is rheostat that controls throttle. So the rheostat part you can watch with a live data tool and the IVS is a bit tough but you should get a normal idle at 800 RPM if the IVS is working right. If not it could possibly idle higher above 800 RPM if not.

-

Defective Head Gasket

Naw not really... I was still standing in the middle of town. Naw. I can get that head off in about 2 hours. It takes even longer to put it all together though. Not the only solution and not the best either. Just because everyone flocks to Cummins like its the best product. You have to remember Cummins doesn't manufacture a lot of parts they buy parts by other manufactures and put there name on it. Remember the big thread about thermostats. Cummins to this day does not manufacture any thermostats. But in the time that I've owned my truck they sold 4 different thermostats by 4 different manufacture names, like the current thermostat manufactured by Mr Gasket. But hey you said Cummins is quality...

-

Defective Head Gasket

Exactly what I said.

-

Defective Head Gasket

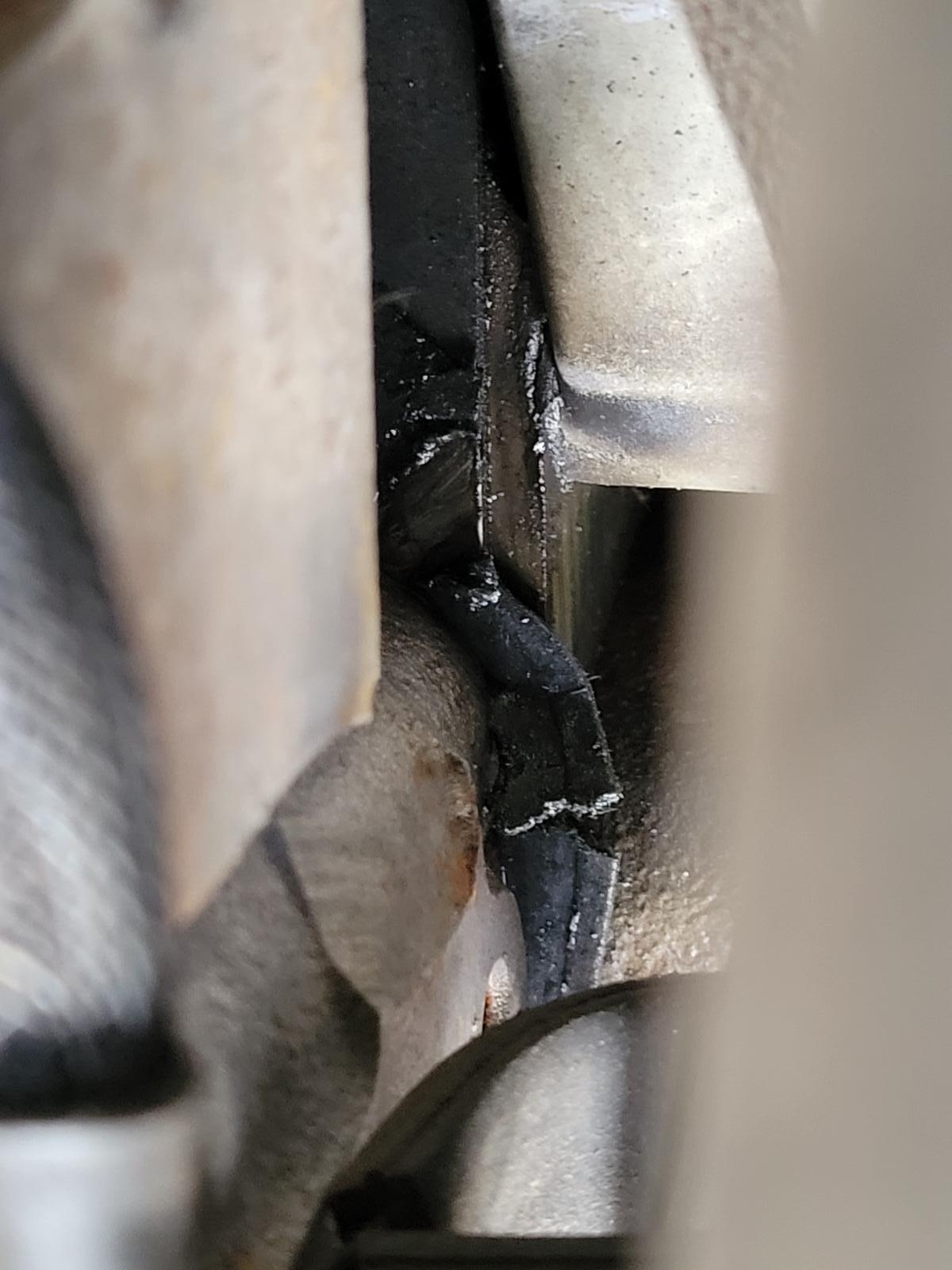

(Shaking my head) Yup. Head gasket blew out again. This time it was a defective gasket. The composite material on the steel plate separated and blew out. Thursday night I gather up my RV and hitched it up and hauled it out to the forest at Smokey Boulder Rd. Came back home the next day I got off work and grabbed The Beast and rolled into town to get fuel. I seen Fire Chief's wife getting diesel fuel. Pulled into Riggins One Stop and parked as I got out I was teasing Matt that was sitting outside smoking a cigarette. I walked over and talled to Melanie about Fire Dept Business. After about 15 minute I walk back over and my truck is leaking. Matt said it was like 5 minutes after I got out of the truck it was dripping. The only thing I noticed was the radiator cap was wet. Released the pressure and checked the level little low but good. Drove over to the store less than a mile and engine was dripping again dripping. I took a good look and sure enough the head gasket separated from the metal plate and blew out. So here we go... Take notice ot the missing chunk of gasket above the tear. That is is steel plate in that gap. No, its not suppose to separate like that. I got ahold of @dieselautopower and talked to Mitchell. I walked out shot this photo and texted it to Mitchell and he said he would call and talk to the head gasket supplier. At 12 noon I got a text back stating the new gasket is on its way. It wonderful have Diesel Auto Power as a part supplier... Thank you gang for handling this for me! Sad part is I got to start all over and do this all over again...

-

Daniel Stern Lighting Sport Headlight Harness

Seems weird. I like the switch back style more so. Clear visible change from white to amber.