Everything posted by Mopar1973Man

-

APPS TPS failure expectation

Timbos APPS would of been a much better solution. If its repaired correctly the error code should be erased and not returned. The only thing that will trip the APPS error codes is voltage that is out of range. Once it goes out of range the dead pedal occurs and the ECM ignores invalid signals till a known good signal is seen. I've been using the Timbo's APPS for over a very long time now and never replaced it yet nor had any throttle related issues. 5 years of travelling for @MoparMom(Rest in Peace) but I did over 250k miles hauling her back and forth to dialysis for 5 years every other day (Tuesday, Thursday, and Saturday) and doing 250 a miles a trip taking about 13 to 14 hours each day.

-

Need a sanity check.. changing careers

Like myself I've been self employed for the last 30 years for the most part. Yeah I've worked other jobs like dish pit at a restaurant. Still in all I've always did my own investigating work of what is needed in the area around me. Currently mechanics are in short supply. I've even gotten smart and talked to the shops around me and offer to take jobs they don't like to handle or don't wanna handle and visa versa. This way everyone helps everyone. I've current got more work than I know what to do do with. I'm up every morning at 5am and out the door by about 6am. Work till noon and hide from the heat till afternoon. Still working for my Well To Do Family. I know @JAG1 and @IBMobile are both self employed as well.

-

front ball joint time

Next set I do I'll cut the top off and push the ball stud out. Them relief cut the cap strike once and it will fall out. Just need a hot wrench or cut off wheel.

-

P1689 Very hard to start after VP44 replacement and ECM reprogram

W-T ground wire mod address the ECM and VP44 grounds. They come from the passenger battery over. The ground behind the starter is fuel heater and lift pump ground.

-

P1689 Very hard to start after VP44 replacement and ECM reprogram

Yup I bet W-T ground mod will fix that.

-

I'm Back, Finally! And I have some good questions/ topics

"Not I", said the fly... Sorry I can't help.

-

VP44 Injection Pump Teardown - How it Works

Best I can add to this is according to the Bosch EFI documentation I last seen was the VP44 required like 60% return flow for optimal cooling and lubing. Then just for fuel consumption values. For 20 MPG you'll used roughly 2.75 GPH. For faster speeds like 70 to 80 MPH can be upwards of 4 to 5 GPH burned. Return rates will change over engine load and fuel demands. Just for fun, I've seen full WOT operation as high as 22.0 to 25.0 GPH burned! Return rates will be at it lowest point now.

-

Pilothouse/RAM3500 build

Latches for your Quad doors. That's pretty cool I'm wondering if you'll have power windows and door locks?

-

Dash Indicator Light Replacement

Ok I've never seen one like that but I'll look for it now. Learned something from you all.

-

Intermediate steering shaft

I have weighed out at GVWR 8,800 pounds and it was right at 50 / 50 roughly for weigh.

-

I'm Back, Finally! And I have some good questions/ topics

Not exactly. But the power wash kicked on loose on the pins so I was able to see how to unclip the rest of them. Not hard.

-

Intermediate steering shaft

What is the axle weights? Front vs rear axle? Typically on average its 60% weight on the front axle and about 40% weight on the rear axle. For example I know the weights of my 2002 Dodge by heart. Front is 4,440 pounds (60.8% = 4,440 / 7,300) Rear is 2,860 pounds (39.1% = 2,860 / 7,300) Total weight 7,300 pounds. Even knowing this I can get the tire pressure correct... My tires are Hankook ATm 245/75 R16 (3,042 pound capacity at 80 PSI) (4,440 / 2) = 2,220 / 3,042 = 0.72 x 80 = 58.3 PSI in the front (60 PSI Front) (2,860 / 2) = 1,430 / 3,042 = 0.47 x 80 = 37.6 PSI in the rear (40 PSI Rear) Might check the axle weights like this and see how much weight is on the rear axle vs thew front axle.

-

Dash Indicator Light Replacement

Never seen it in that location. This is the typical location I know of and always seen. Unless that happens to be only a 98.5 thing... Never seen it on the cluster with a light. As for doing LEDs that is very possible just count the amount of bulbs you need. Make sure the bulbs match the color of lens to show correctly. For example if the tail lights are red lens you shouldn't use a white bulb. You see the bleeding of the other color of the spectrum like green and blue and not appear right. Where a red LED and red lens shows correctly. Changing cluster colors might be a bit weird so be aware there is a green tint... I've not pulled my cluster to see what is there rubber cover bulb or green plastic lens. Externally I'm all LEDs on my 2002 Dodge and love it haven't done the cluster yet but its just a simple bulb swap. I would also measure the new load on the cluster lighting and change the fuse to match the loads now. Most likely change from a 5A to either 2.5A or 1A fuse. Don't need 5A worth of power when most LEDs barely take milliamps to run.

-

Dash Indicator Light Replacement

Again the cruise indicator is in the odometer display and typically on the 98.5 and 99 I've seen its as a yellow to amber color on the odometer. Again there is no light bulb. From 1994 to 1998 was the cruise light was on the steering wheel as a green LED. From 1998.5 to 2002 the cruise light is in the VFD on the odometer From 2003 to 2007 the cruise light is a light bulb on the left side of the cluster.

-

VP44 Injection Pump Teardown - How it Works

Backwards... My injector return and VP44 return arr both in the fuel basket. I draw from the fuel tank directly. Never from the basket. Like I said I've been having 105 to 118*F weather here in Riggins, ID. Still can keep the fuel temps lower than most. As seen on the overhead of my 2006 Dodge I ran last Friday... Normal never run the tank below 1/2 a tank for better cooling too. Below 1/2 tank you can start to see a climb in fuel temps. Very stable 15 o 17 PSI fuel pressure from idle to WOT at 100 MPH on a AirDog 165 pump with a AirDog 150 filter body.

-

Turbo Help

Out of balanced. If it truly balanced it would never make contact no matter how fast it was spun. Compressor wheel make sure its clean and dirt is riding on the compressor wheel. If its making contact it because it out of balance even little bit.

-

Dash Indicator Light Replacement

Ummm... Last I checked the CRUISE is not a "light bulb" but part of the ODOMETER display, part of the vacuum fluorescent display (VFD). All 1998.5 to 2002 where displayed part of the odometer display. If the cruise light is not coming on it could be a bad cruise switch in the steering wheel. Bad clock spring. Other wiring issues. Basically in a nutshell the when you press the cruise on and off it should send a voltage to the PCM to tell it to turn on the cruise. Its a one wire system and based on voltage. Like in my case the Coast button failed on the right side. The voltage was no longer present for this function so the PCM never gave any coast or dropped the 1 MPH. After replacing the switch super cheap off RockAuto everything works again. Function wise the PCM provides 5V and the different buttons have different resistance. So as the button is pressed a different voltage is sent back. If the voltage matches a function the PCM will do as commanded. If the voltage does not match then nothing might happen, different function might occur, etc.

-

I'm Back, Finally! And I have some good questions/ topics

Vent pieces can easily be popped out and traded to the new bezel. I found this power washing mine last year.

-

Intermediate steering shaft

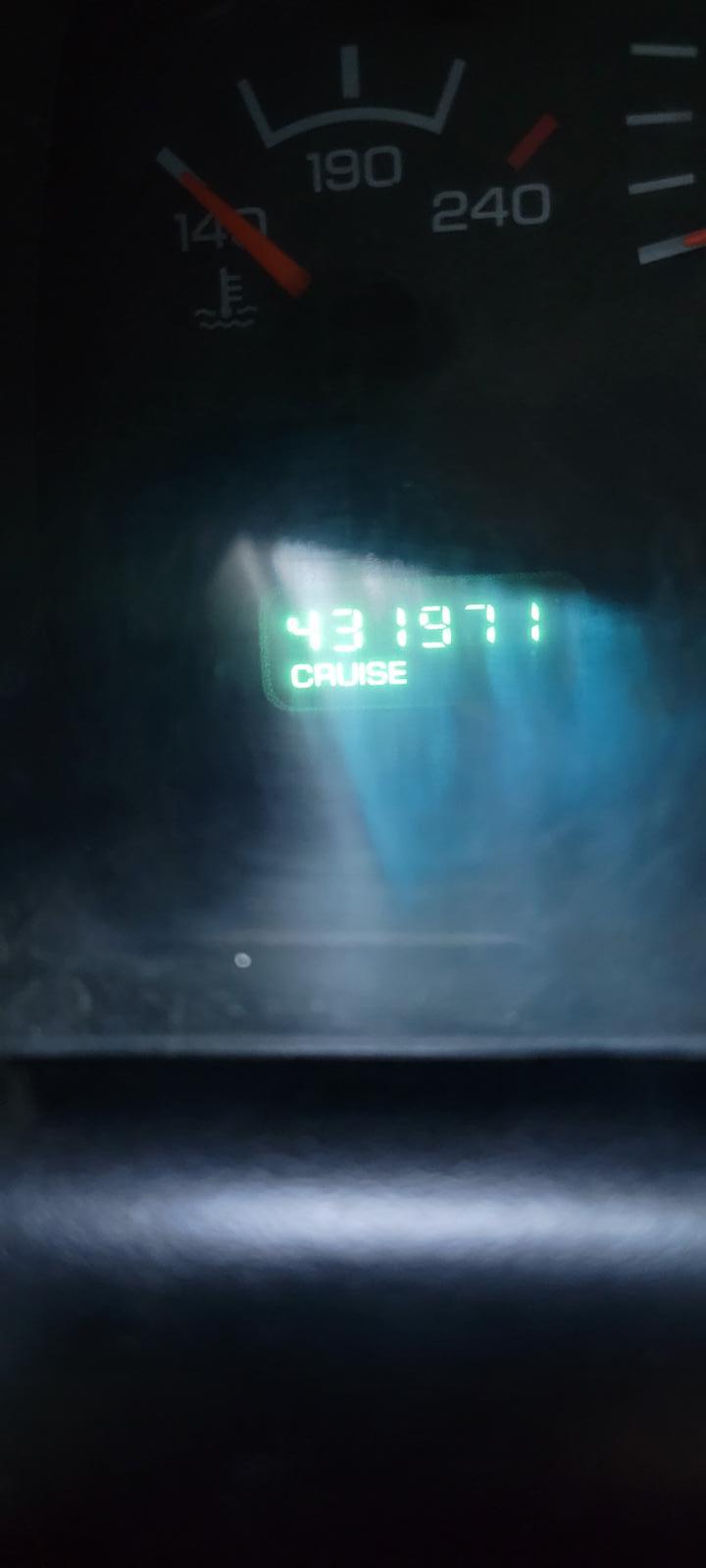

Like on my 2006 Dodge I need to remove the 2 inch leveling kit. This will bring back the caster for the tracking. As you use leveling kits you change 2 things. First thing you change as you push the axle downward is the caster. You make it more neutral which causes the wondering lack of caster. The second problem since I've got a "fixed length" 3rd gen track bar is now the thrust angle is wrong. As you push the axle downwards with the leveling kit the track bar is a fixed length so now the thrust angle is wrong pulled towards the driver side. (Enhanced tire wear)This all applies to the 2nd gen bodies the same way. If you planning on using leveling kits you need to consider both angles. You would need adjustable track bar to reset the thrust angle. Then you would need adjustable lower control arms to recover the caster you lost. Where the 2006 Dodge has over sized tires, lift kit and other mods which all causing drivability issues. This is why I've never had a single issue with my 2002 Dodge with steering I've never added leveling kits, oversized tires or anything to mess up the geometry of the front axle. This why after 431k miles and counting ball joint last a super long time 250k plus, tie rod ends lasted 350k plus, etc. All my geometry is correct and never had these kind of problems on my 2002.

-

Strategies for saving/ increasing net worth

My suggestion buying gold or silver.

-

VP44 Injection Pump Teardown - How it Works

Hmmm... Just to challenge this quote a bit. Ok, then please explain with my typical 15 to 17 PSI lift pump pressure (AirDog 165) I'm typically 10*F to 15*F cooler in fuel temp over most with a stock lift pump or weak lift pump? My typically fuel temp is about 110*F to 140*F maximum. There are members here with fuel temps much higher at 150*F to 160*F. Being most claim the VP44 take a huge amount of heat soak from the block. Still I have cooler fuel temps. Keep in mind I've been seeing 105*F to 118*F temperatures here locally for outside temps.

-

VP44 Injection Pump Teardown - How it Works

Agreed. I don't rely on the internal vane pump to keep up with the demands either. This is why there has to be some positive pressure. If you seen the timing piston in the VP44 I've got you'll see a very galled up piston plus the bore. This particular case it was more a lubricity failure also could be from low fuel pressure since fuel will heat up in the pump without good return flow so now the fuel thins out and the parts start to wear.

-

Turbo Help

Be aware just changing the timing curve just a little bit you might gain more on the Stealth 64 turbo. Bigger turbos typically need a bit more retard to get them spun up this is why the small HX35 (with mods) did better on EGT's. More you advance timing the harder it is to spool a larger turbo. When you retard the timing a bit your are blowing more fire out the exhaust port to aid in spooling the turbine.

-

Miss and long-term Park vehicle.

You would be better off draining the fuel tank and fuel system. You'll fight long term storage of gas. Like all the gas powered fire trucks we have have issues sitting in a shed for months at a time. There is no amount of fuel additive that will keep it fresh. I rebuilt a carb on our old 1972 Ford F550 structure truck. Again fuel additives used but the carb went toes up fast. One reason we been ditching all our gas powered equipment and trucks and switching to diesel powered way less issues with long term storage of diesel fuel. Now I can say without a doubt I've got a 55 gallon drum I keep gasoline in. As long as the bung cap is tight and sealed gas will last forever. Last time I filled the barrel was 5 to 6 years ago. Still fresh. This is why I suggested draining the tank. Fuel tanks are not air tight so the ethanol will evaporate and some of the fuel hence the lacquer problems. Just like the 1977 Ford I've been working on. The fuel tank was lacquered up and all the seals on the carb was shot. Long term fuel contact with hoses, seals, and gaskets will degrade.

-

VP44 1998.5 Eyes Burning, Bad Mileage Help

Exactly. This is why is start at 13 degrees so it doesn't buck. There is enough retard to prevent bucking.