Everything posted by Mopar1973Man

-

Block heater extension cable

The element is a 750 watt 120 VAC element. 750 Watts = 120 Votls x 6.25 Amps. Heck its +19*F (-7*F) outside and the truck is outside in he cold I won't even think about a block heater till 0*F (-17*C). Even then I'd only plug in hour before I need to leave. Parked outside the heat is wasted in the into the air. If I was parked in the unheated shop I would plug it in and leave it being the heat is not wasted but heating the shop a few degrees.

-

The Future of Trucks

That's the stupid part everyone thinks electric vehicles are free. Someone is paying for that power either going to be a rise in taxes or just your home power bill. trust me when I'm sitting here its a mere +63*F in the house, +19*F outside, I'm running out of firewood. Yeah I know this month is going be a $200 plus a month just to keep warm, now toss in a massive battery for a vehicle, that draws power like my electric dryer or my heat pump. You can safely figure in just doubling my power bill. Regardless your still paying for the electricity some how. Power plant still emit CO2 into the air just as much as you drive your electric car around just emitted from the power plant not your car. Still not fixing the issues of reducing CO2 emission. Still in all HP (fuel) to HP (electric) is going to require X amount of amp hours (electric) stored to travel. For mountain area like where I'm at just not effective. I'm now seeing electric cars once in awhile out run there charge and left stuck. Currently if you leave Boise there is NOTHING north to recharge a electric vehicle I know Ontario, OR has a few charging stations but nothing north of Boise. Lewiston ID I've not seen any charging stations as of yet unless they are hidden down a side street. Kind of like when I was buying my truck there wasn't any diesel fuel available in my area but maybe one or two stations and expensive. Now with the amount of diesel vehicles diesel fuel is available just about every where. I almost opted for a 60 fuel tank where purchasing my 2002 Dodge.

-

Got a computer question and need some advice/help

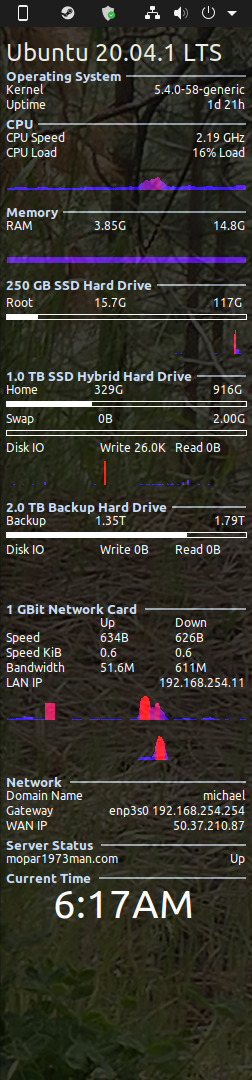

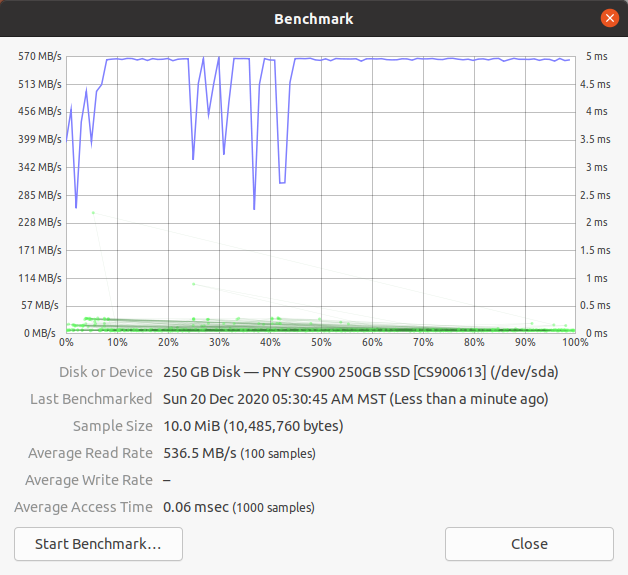

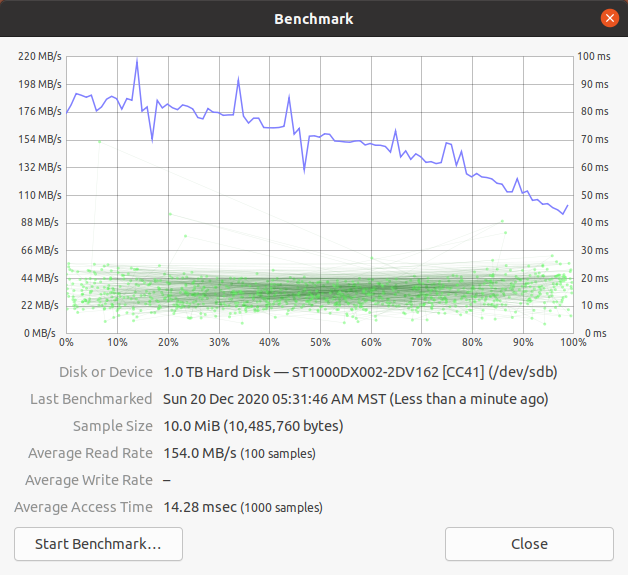

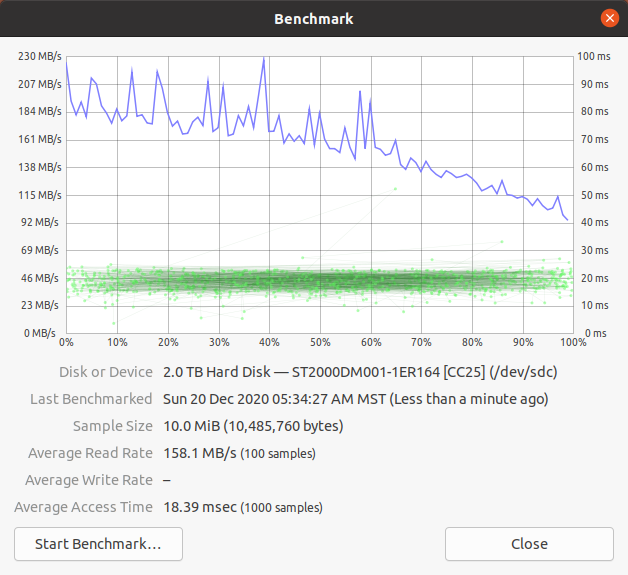

If I ever got you to jump ship to Linux it would be even faster. Windows is extremely heavy system load wise. A peek at my Conky panel with all my system stats. Fun part is this machine was built back in 2006 with AMD AM2 processor (4 core). Still quick! Take notice I've got basically 16 GB of RAM (1.2 used for Video RAM). Only need 4 GB for just working in Ubuntu Linux. If I fire up Windows 7 (Virtual Box) it will suck up every last drop of RAM instantly. As you can see I've got my 250GB SSD Drive on my ROOT folder so only my read only files are there this will extend the life of the drive. Being most SSD are good for 100,000 writes to every sector. As you also see Linux created a 2GB swap file but no used at all. My writing drive is the mechanic hybrid which is a 1 TB in size. Then my Backup drive which Linux does automatically every daily is a older 2 TB drive. Yes the Hybrid drive works great for long sequential reading where random is still not stellar vs straight mechanical.

-

Electrical Info Needed - for 1999 Ford F53 Motorhome Chassis

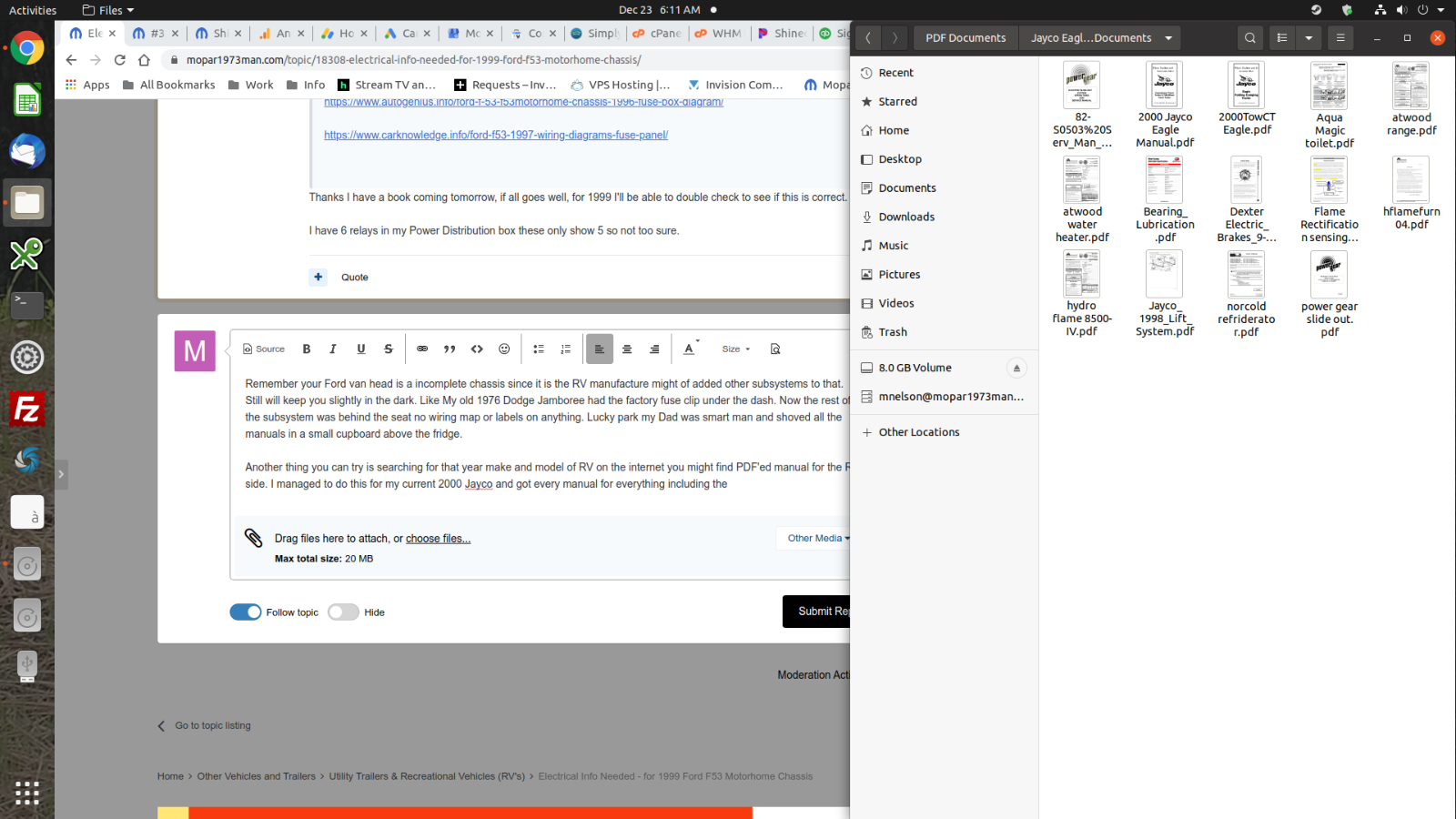

Remember your Ford van head is a incomplete chassis since it is the RV manufacture might of added other subsystems to that. Still will keep you slightly in the dark. Like My old 1976 Dodge Jamboree had the factory fuse clip under the dash. Now the rest of the subsystem was behind the seat no wiring map or labels on anything. Lucky park my Dad was smart man and shoved all the manuals in a small cupboard above the fridge. Another thing you can try is searching for that year make and model of RV on the internet you might find PDF'ed manual for the RV side. I managed to do this for my current 2000 Jayco and got every manual for everything including the RV manual. Take a peek...

-

Heater/HVAC Air only goes to Defrost Vent

You've got a leak some where. Double check your CAD axle system really common for vacuum leaks in the CAD system. Vacuum should be instant. No waiting to build. Vacuum leaks will make everything slow to react.

-

EDGE CTS DISPLAY MONITOR

Yes a replacement screen from Edge would work for any vehicle... Just run out to Amazon and get a any random screen is what I meant. That won't work.

-

Dash brake light randomly illuminates

Actually... The tail light switch (brake pedal) that can be reset and re-used. There is a ratchet kind of stem adjustment I managed to open that switch up and extend the plunger and re-assemble with no issues. As for the Parking Brake light on the dash its the cable slack adjustment needs to be tighten a bit more. The pedal is not fully returning up. Be careful rusted cables will do this same thing but as you adjust you just start dragging the parking brakes because the cable is too rusted out and sticky.

-

Milestone, sort of........

Kind of like myself... Bought new in October 2002 for $32,000 with only 43 miles on the odometer. Now Been back and forth to Boise- Ontario so many times in 5 years that I've now racked 424k miles (roughly 1.1k to 1.5k a week) on the odometer. Engine is stronger that a 5th gen (500 HP to the ground). Still going strong. Mine is another that will be around till the frame rust in half.

-

What to look for in 1st Gen?

Forgive me on my last post think about 12V 2nd Gen I don't know why...

-

From Edge EZ to Quadzilla is there anything I need to know?

The old Edge Products elbow is a fixed boost elbow which typically stops about 35 to 37 PSI. Ran it for years and good for that tuner only truck with stock injectors. Now I'm running a China boost control like @IBMobile and works OK. Better design but never really got it adjusted. Being I've still be able to go to 47 to 49 PSI on my HX35/40 (60/60/12). +150 HP injectors and +180 HP Quadzilla. Heck my last trip to Lewiston, ID I filled in Lewiston made it back home with a bit less than 7/8 of tank remaining. Power wise I turned it up to kill and the tires had problems holding the pavement in town. Even @Wet Vettecommented about the tires kept squeaking every time I launched from traffic lights. I know I'm rambling... But @leetyanother way to look at Quadzilla level and better way of explaining. LEVEL 0 - Stock Quadzilla is turned OFF and stock ECM program is running. 1 - Valet Mode 2- Stock with Timing - No mater what your fuel map is it will use the defuel section up to 100% stock power and stop! 3 - CANBus fuel Only. You full fuel map is used but NO wiretap. 4 to 15 this is all wiretap modes. Divided up so you casn have slices of 10% of wiretap. I typically set for 7 and that gives 25% slices for wire tap. Typically now I use level 2 as my daily driver. Very smooth fuel, EGT max out at 1,100*F. Good traction even under heavy throttle in wet conditions. Snow can still spin fairly easy at even 2 or ZERO.

-

EDGE CTS DISPLAY MONITOR

Most likely proprietary to Edge Products. The display has to be able to decode the video information properly. I seriously doubt just any random screen will work.

-

Heater/HVAC Air only goes to Defrost Vent

Yup. @dripley is right. The rubber pieces do fail over time. The only vacuum used is typically the cruise control (auto) and the HVAC controls (all).Then the rare type like me vacuum exhaust brake (optional).

-

EDGE CTS DISPLAY MONITOR

True. The brain is typically under the hood ties to the CANBus for part of the info. The other part of the info comes from the OBDII port. The cable should have the right MAP sensor plug, and the right CANBus plug. There is 3 different MAP sensor plugs between 1998.5 to 2002. Then there is 2 different CANBus connectors between 1998.5 to 2002.

-

Irregularly TPS voltage. new timbo installed

W-T ground mod done here and kept my cruise control smooth now. I'm also Timbo's APPS user but when the AC noise got bad it will accelerate up to 75 MPH on its own the coast down to 55 or so and start over randomly. This with fly by cruise control. After the W-T mod no longer even an idea of it happening for over 2 years now.

-

Changed turbo and exhaust manifold - now I have white smoke under acceleration

You did injectors right? There is air in the system I typically take the truck and go out and do a few WOT runs for short burst to bring the rail pressure up to MAX to push all the air out of the lines. The white smoke is because the timing is retarded. This is due to the fact air is compressible so there is timing lost compressing the air bubble and the firing the injectors. The only way to get rid of that is a few WOT run loaded and it will blow the air out on high loads. If not like in my last go around on 7.3L Ford double check your injector wiring this includes CR engines too. They will run rough and idle weird and free revving seems weak and lots of smoke. Totally normal. Go drive it and blow the air out typically in the first run she will clear right up.

-

Milestone, sort of........

- Two Stroke Deleted 2018

Yes. Common Rail engine tend to play good with 200:1. 24V older engine can play with as rich as 128:1 ratio. Basically 1 ounce of oil to gallon of fuel (128 ounces). The 200:1 was designed more around the pilot injection. If that is switched off you can run the 128:1 ratio. Multiple pilot injections of fuel and oil tends to flood hence the 200:1 ratio.- Dash brake light randomly illuminates

Make sure the slack adjustment is tighten properly. If the slack is excessive the pedal will hang down and touch the pin switch for the brake light. So ad just a few turns to the slack adjustment on the cable and it should stop.- What to look for in 1st Gen?

Sorry for my post I was thinking about a 97 I was last working on not to long ago. Yeah its a 1st gen... 1989 to 1993...- Got a computer question and need some advice/help

Works mostly for sequential reading like page 1, 2, 3, 4, etc. But not when its sector 512, 97, 34, 1,024, etc. There is no read ahead possible being that is testing more the ability to hunt sectors down fast use mechanical drive. Hence the match in performance. Linux has a internal file function called "preload" and I do have it loaded up. It reads common files up to memory and call files from memory cache more than physical drives too. Long way from how Microsoft works. As for Microsoft I've seen a few brief articles about splitting the partitions up in the same style but it bit more technical than how Linux handles this. Linux gives you this option during installing the actual OS. As for Windows the last time I played there it didn't give options for partitioned drives during install. I'm sure there is a way but how hard is it for the end user?- Hello From Tri-Cities, WA

I'm buried out in the Midwest of Idaho. The member map is a helpful tool for getting to know other members and possibly some help.- What to look for in 1st Gen?

The only time I've seen blow by is guys running large shower head nozzles and burn a piston a bit and then the blow by starts. For stock engines typically they are way under fueled to do much harm at all. Don't get me wrong excessive heavy loads and heavy throttle you can still do damage to a stock 1st Gen. The biggest thing is finding out if the KDP is handled? Gear case cracked or leaking? Fuel heater been removed or is is leaking? Lift pump in good condition? Typically about 4 PSI to 6 PSI fuel pressure. Valves been adjusted? When was the injectors and the injection pump possibly rebuilt if at all? Injectors are typically wore out about 100k to 150k miles. Injection pumps get some wear in internals not as bad as the VP44 but still P-pump do wear some. Timing? Did it slip? Common for all 12V p-pump engines the gear is without a key so its possible to slip timing. Rest is taking the time to look at all fluids and levels look for clues. Crawl under the truck and look up. I typically go truck shopping with overalls. Spend more time up-side-down under the truck there is more clues. The top side is typically power washed to hide leaks and other issues. I could go on for every things to look at... I would most likely buy it after a quick inspect then tear into things even deep and fix it all up solid.- Milestone, sort of........

Well truthfully no... There is no air for the roster to even crow. No air to push through his vocal cords...- Electrical Info Needed - for 1999 Ford F53 Motorhome Chassis

Best thing to do is contact the RV manufacture and see what they have to offer being the Ford chassis is sold as incomplete and its the RV responsibility to finalize the wiring maps and service manuals for the incomplete vehicle. This was a reason why I gave up my 1976 Dodge Motorhome (Class C). Dodge van head and then Fleetwood (I think) build the rest of the RV. Being Fleetwood would have all the info on that incomplete. You could look for Ford vans incomplete wiring map possibly find something.- Got a computer question and need some advice/help

Ok here is my example I'm on Ubuntu Linux. So my SSD drive is 250 GB drive. I've got all my Linux ROOT files on the SSD. Being Linux gives me the choice of placing all the read only files in one partition. So the 250 SSD has a partition for the Linux ROOT and then space for Windows 7 (VirtualBox). This ROOT partition is only system files and are typically only read from here. The only writes that might happen is configuration changes or updates. Then my storage drive is a 1 TB (1,000 GB) hard drive. Now Linux allows me to specify my HOME partition. This is where all your store of files, downloads, pictures, music, videos, etc all stored. This allows me to keep the writing stuff off the SSD extending my hard drive life of the SSD. Being most are good for 100,000 write cycles. My method reduces that write cycle to only when I run my system up date. This drive is a hybrid both SSD and Mechanical. sudo apt-get update sudo apt-get -y upgrade sudo apt-get autoremove sudo apt-get autoclean Then my massive backup drive which covers both the local machine and second backup of the website when I'm doing work. Ubuntu does a awesome job of backing up everything. This is a older mechanical drive that is even slower at 5,400 RPM. - Two Stroke Deleted 2018