Everything posted by Mopar1973Man

-

trreed's upgrade thread

Take the truck to the north pole it will stay cool enough while you pushing Nos, propane, and shot of water/meth...

-

Good injector combo for edge users!

Mopar1973Man replied to Tittle Diesel Performance's topic in 2nd Generation Dodge Reliability / PerformanceYeah any bluetooth device with a screen. Tablet or cellphone. You can even use a Android stereo like some other people have.

-

Electrical Help - Power Mirrors and Dome Light

Most likely the mirror motors are locked up or shorted. Or yeah it could be the switch is fubar too.

-

Good injector combo for edge users!

Mopar1973Man replied to Tittle Diesel Performance's topic in 2nd Generation Dodge Reliability / PerformanceProblem is Edge Juice, Edge Comp and Edge EZ are built around stock injectors the biggest you can go without huge smoke is a +50HP injector. I Ran Edge Comp for years and tried stock injectors, RV275 and +50HP whih the +50HP injectors where getting rather smokey and there wasn't a setting that would handle that smoke. Now if you drop the Edge product and switched over to Quadzilla you can set your lead in fuel at BELOW stock fuel levels which will remove that smoke. I'm running +75 HP injectors now and smoke free.

-

trreed's upgrade thread

Propane will burn... Nice shot of propane will keep the lag down.

-

Airdog 150 problems

You getting the newest version. 4th generation. Mine is back from 2006. No. Still here in the states. I got my new head no questions asked.

-

trreed's upgrade thread

Put it on a toggle switch. Toggle to charge the tank then toggle it off to run normally. Still can have air. Crazy idea I know.

-

Power distribution center burnt up

Like I look at my ground in the driver side kick panel and left it alone. Good ground. Closed it right back up.

-

Morning Pic For Today...........Post A Pic around your place.....

Ummm where is your cargo? Empty truck don't pay. Hmmm...

-

Electrical Help - Power Mirrors and Dome Light

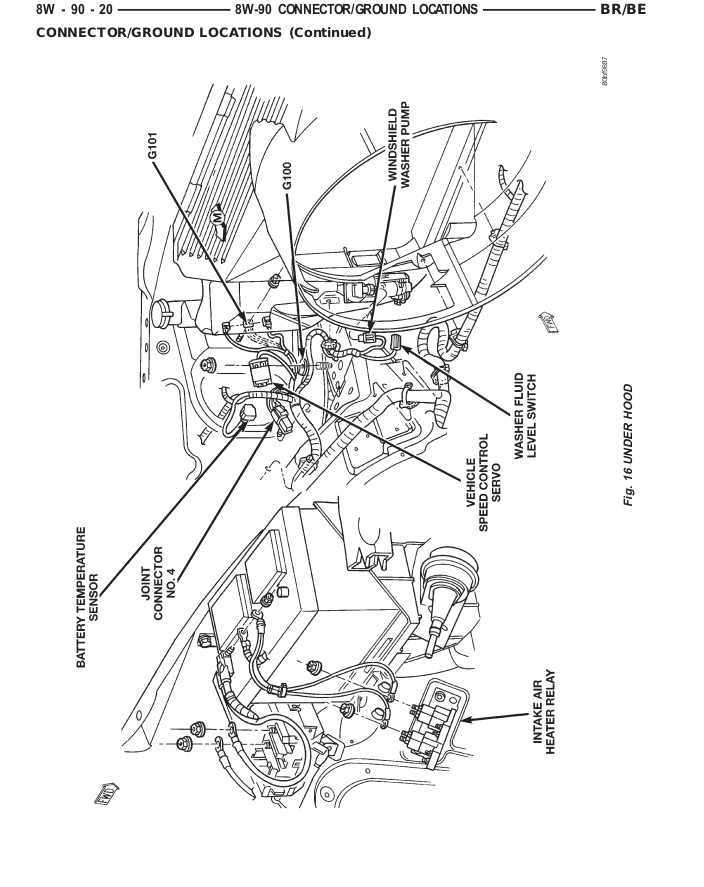

Joint connector 5 require for dash removal just to access that connector which is buried above the steering shaft bracket. C203 is right down at the master connector going back through the firewall.

-

CR Injector failures and upset owners

Join the club...

-

trreed's upgrade thread

I bet you could mount a air tank and tap into the boost pressure and use that for air horns. Yeah you need a check valve.

-

Winter is coming - Did you change the air in your tires?

Time to change the air in your tires from Summer air to Winter air for optimal performance.

-

Electrical Help - Power Mirrors and Dome Light

Now I've got to wait till the next time this happens. Weird part is that I've only check connectors and wiggled wires now I'm back to working again.

-

trreed's upgrade thread

I just added a full 1° degree across my spectrum. Cruise timing for my rig is optimal at about 21°. I've tried backing down to 18° for cruise timing and dropped to 18 MPG. I know this is the wrong direction. What I've done is got away from the +3° spread between bands and went to +4° spread between bands and start out at 14° ado plus 4° up. I know my max is 27° after that I get bucking. The +4° spread works out awesome giving me a nice retard on the low end of the RPM's and then pulling up the power rather quickly so quick the tires get overwhelmed. This is good now I'm going to build around this. This means I've got a breakaway point for torque and can eat a differential kind of like someone I know. Now it time to go hunt for big tire 4th gens... Time to whip on the pup's..

-

LED lighting - Interior lighting

This is what my mornings are like just trying to pack up and get going. I've got to do the dark thing for 6 months now. This is the old school bulbs and we'll see what the new LED's look like.

-

Electrical Help - Power Mirrors and Dome Light

The two exactly I'm looking for is the ground for the power mirror movement (not heat). Then I'm looking for the ground for the dome light. Could you post a picture of what you got? @Haggar Please?!

-

trreed's upgrade thread

80 PSI that's a lot of boost pressure. Wow! Since I've done the head gasket on mine and the ARP studs I've been re-tuning and capable of spinning that HX35/40 up to 45 PSI as a small single. The funny part, that only with 1,200us of wiretap. Then the other problem is the 245's don't like it much being they tend to lose grip with the asphalt.

-

Power distribution center burnt up

I've never done any of my grounds. The only ground that got attention was the W-T ground that's it. I've never clean any of mine. I do not want to scrub the paint off and have the metal start rusting which is worse than just leaving a "good ground" just being surface dirty.

-

VP44 testing

Even when I've got to travel where I go there is no option for plugging the truck in but I've never had any problems with getting started on cold winter days. I might keep the truck in the garage but once I leave anyone guess on how long it will be parked and how cold it might get. This is why I don't depend on the block heater at all. If you do then your just going be like the Ford Powerstroke that have trouble starting at the first sign of cold.

-

VP44 testing

My truck tends to be parked in an unheated garage but since there is plumbing in both garages the temperature typically stays just above freezing. When temperatures outside fall to ZERO then I consider using the block heater. Not to make the truck start easier. It's to heat the garage up slightly to keep the plumbing from freezing. The radiant heat from the block is not wasted then. Very very rare to see temperature here at the house that cold. Now New Meadows, ID yeah it very common to see at least -20*F. Coldest I've seen so far passing through is -30*F. Wild part, is within 1-hour drive the temperature rises again so head from New Meadows, ID to Council, ID and it will rise nearly 20 degrees or more. For guys parking outside and attempting to use a block heater is a pure waste when there is blowing cold wind around the engine and heat is wasted to the air outside. Even if you have a tarp shed to keep the wind off the truck will heat much better than heating in the wind. 750w engine heater isn't powerful enough to combat minus temperature weather.

-

Power distribution center burnt up

-

No Start

- VP44 testing

Not a problem. Send it back to Nick he'll rebuild that easy. I just bought him 100 units of parts for building more.- Here is a Strange.... 47RE

Engine running backwards? Check the air filter for carbon that would be a sign of engine running backwards. Other than that the transmission needs to be rebuilt most likely. - VP44 testing