Everything posted by Dieselfuture

-

Yet another FASS ball & spring post

@SilverMoose it's routed through vp and continuesly flowing back to tank if pressure overcomes overflow spring that supposed to open at 14psi. And that's what cooling vp.

-

Head gasket leaking oil

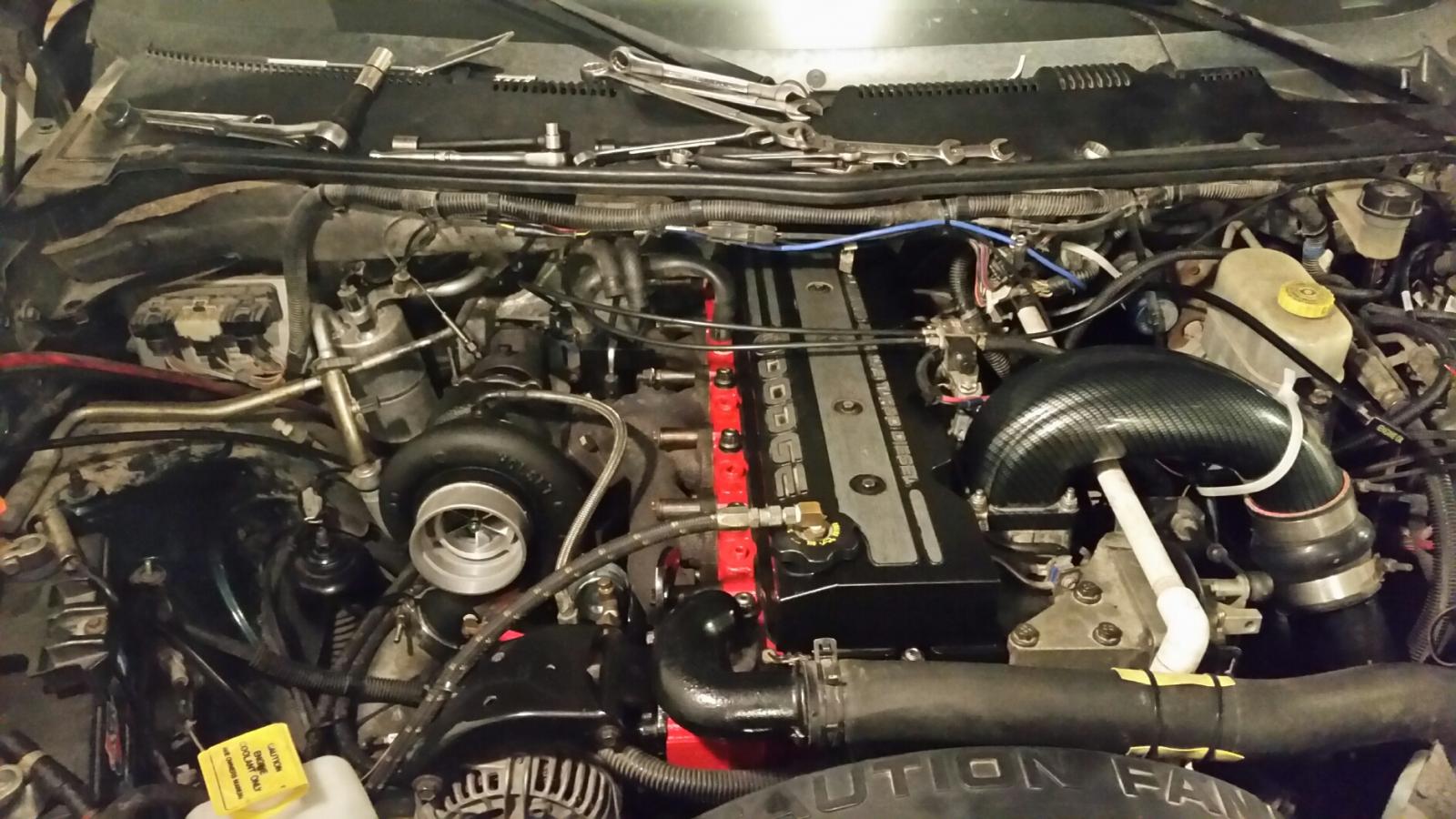

So after another 3 attempts of trying to fit it without a leak I gave up and used more lapping compound and got a nice imprint in compressor housing. That's what finally did it is a smove surface. So I'm taking another star off, they now get 8 out 10. I'll be calling Zach and letting him know. If he knows what he is doing then his help needs to know too. In my mind they should bench test housings for leaks. And using bolts that are beraly in is just ...... I don't think anything was done on purpose just simply things got overlooked. About the rock solid bushing, it fixed more loud clunk I had when turning onto a curb or bump, and it does feel a bit smover in column. Still valve very faint click lossnes but over all it improved. @dripley @trreed Also something to add, after fixing boost leak it spools sooner now, and on the same tune when I could only hit 29-30 psi I now can get 36 and that's pretty much maxed out canbus and 1800 wire tap. At full throttle at 3000 rpm still blowing some smoke, I would think it should spool more if there is unburnt fuel. On my economy tune I have almost no smoke at all on level 3 is where I keep it and I can very easy max out canbus and 30psi is all I can get without wiretap. But overall I'm happy with the outcome, best thing is no leaks so far, and I've been fricking out a bit as much as I bit it after new head gasket.

-

Head gasket leaking oil

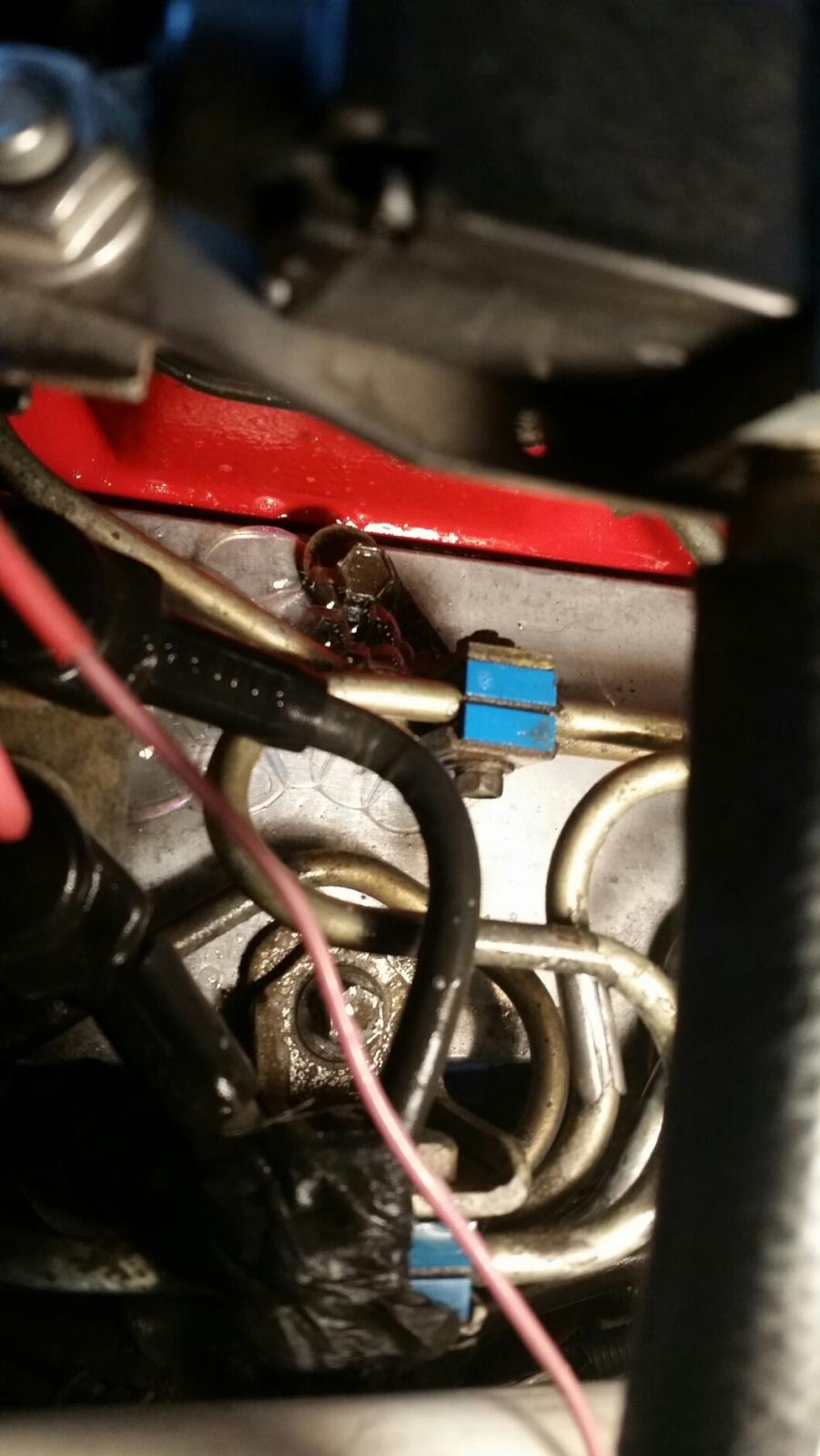

So I think I found part of the problem. The lip on compressor housing that seals against bearing housing was pitted, so I used valve grinding compound and made a nice line like on a valve when you lap them. Actually small machine marks from bearing housing transferred to compressor housing. Now it doesn't leak till about 20 psi and then it still bubbles. So now I'm thinking it's the clip maybe, but it's in as far as it can go. So now I'm starting to consider rtv, it's not right but kinda running out if options, already wasted enough time. Also found a small leak on intake plenum, had to put more dope on threads. You can see a bit better how exhaust housing is peated.

-

Head gasket leaking oil

Well I'm now trying to figure out how to stop this housing from leaking, I'm about ready to use rtv. I rotated it and had no luck stopping this pretty good size leak. Any ideas. And tested waste gate and my boos elbow. Waste gate by it self opens around 29-30 and I got boost elbow adjusted to open at 38.

-

Which injectors for compounds?

This may be an option http://www.mymoparparts.com/auto-parts/1999/dodge/ram-2500/base-trim/5-9l-l6-diesel-engine/electrical-cat/alternator-scat

-

Ceramic Clutch

- Head gasket leaking oil

Do you guys think I need to change oil after what I did. It looks good and I have a bypass filter too. Kinda feels like a waste of good oil, but if there is a good reason I'll change it. It has 3k on it but still somewhat clean on dipstick. No moisture observed. Another thing is I flushed my cooling system like 7 times and every time I went for a few mile drive and drained water out it looked rusty. I think our city water is corosive and that's what caused it every time. So I flushed it wit distilled water and put coolant back in. This is what I was draining every time. But I would get it all out every time too, after driving a bit that's what drained out. By the way I beat the crap out of the truck today trying to figure new turbo out, so far so good- Yet another FASS ball & spring post

I think anything over 20 is not needed, and of course stay above 14. I believe the reason for wide range swing is restricted fuel lines. You can try to squeeze that spring all the way over night and see if it comes back to 20 or so.- Quadzilla V2 Custom Tunes

I think I may need some help with tuning. I now have 62/67/12 made out of hx35/40 and 75hp 8 hole injectors. It's definitely laggy compared to my hx35 and 60hp I had. But I did little bit of turning and it got a little better. My starting point is 80 on canbus with 3 for increase. http://www.rapidtables.com/calc/math/exponential-growth-calculator.htm My biggest problem or maybe not a problem, is that before I changed turbo from hx35 to current l used to be able hit 45 psi (passed 35 probably nothing but hot air ) pretty quick, and now I'm struggling to hit 25. Max I hit for psi is 30 with canbus maxed and pump stretch at 1200. Another thing is cursing at 60mph my canbus was maybe at 600 and now it's at least a 1000 and boost went from 7-8 to 3-4. Is it just the nature of bigger turbos. Does anyone else has a similar set up that can post their tunes. Daily, economy, tow etc. Edit: Had a boost leak on new turbo, it's much better now on lag and canbus is down to 7-800 from 1-1100 when cruising. Still trying to figure things out.- Head gasket leaking oil

Did it again with maxed out canbus and wiretap at 1200 and got it to 30psi, pretty sure it pulls a lot harder then before at 30. I'll probably need 100hp injectors for this turbo to make it ideal, but will use what I got for now. My starting point for canbus is 80 with a 3 fore curve, by 20 psi canbus is maxed out or even sooner. Starting at 80 still got some smoke but not bad, clears out for the most part. Will be doing lots more testing.- Head gasket leaking oil

Ok got to drive it a bit. First I didn't have a thermostat in and temp never went above 134, my warm up setting is 140 so it was on default profile. Most boost I could get standing on the pedal was 20. It does spool slower and not as high but I think once I get the qwad diled in it should be much better. When I put thermostat in I was able to get 26psi on level 3 on my economy tune, which is more smokyer on take off now, injectors must be that much bigger. I'm at 90 on start canbus will try 80 and ramp it up quicker because once that turbo start to spool around 15-16rpm it gets up in boost quick. Ether way I need to spend some time tuning now. Definitely more whistle out of exhaust now, sounds like mack truck, I did put my silencer ring in, and I don't think it changed much up front.- Head gasket leaking oil

It reads 32- Head gasket leaking oil

Well got it running, didn't have luck without cracking lines, did 135. Now I got another problem my quad egt reads 480-500 with truck idling, took probe out of manifold it reads 1800 something. I think it was getting glitches before I did this job so maybe probe is junk. Any ideas if I can reset it?- Head gasket leaking oil

I'll try without cracking any lines and see what happens, really don't like fuel running down the head on new paint and then for several days you can't tell if you got a leak or its just left over fuel getting hot and pushed out through the nut. So you kept tightening the line and it doesn't need to be. Thanks.- Head gasket leaking oil

Which lines do you usually crack open to get truck started, 135? I can never remember @jlbayes @TFaoro @Mopar1973Man @trreed Getting ready to fire it up, and will it hurt to just run water with no thermostat for now, till I get it running. Maybe even drive around a block few times, then I want to flush it all out, oil and coolant.- Head gasket leaking oil

I have a boost elbow on my original turbo, I took it off and put it on new one. Also found out that it was turned all the way in and that is probably why my waste gate never worked, I cleaned it few times but since it was not in use it frost up again. This time I turned it out and going to see where waste gate is set at and then I'll turn it in till about 38-40psi and call it a day.- Head gasket leaking oil

Alright guys and gals, got my turbo today. I'm giving it 9 out of 10 and this is before driving the truck. Came with cnc machined beer opener. On first glance it looks good, on closer observation I've noted and older more pitted exhaust housing, very similar to mine( wish it was a bit better ). But I'm sure they would not send it out if they were not sure. Bearing housing is brand new compressor housing is used in very good shape ( I had to re clock it ) I'm guessing it's a hx 40 machined out to fit 62. What I did not like is flange for the exhaust brake (which is also new) was bolted with too short of bolts, literally 1.5 to 2 threads in. I reused bolts from my old turbo, (not original ) when put my exhaust brake on I changed them, but pretty sure factory ones were still longer then what this turbo came with. Reason I even took them out is I was going to reuse my old flange but decided not to, they look identical. But because of that I found short bolts. Here are some pictures, turbine is considerably bigger and so as compressor. I can only emagine bigger ones.- MPG help

https://tiresize.com/calculator/ 285/70/17. 102.7 inches 265/75/16. 99.4 inches 63360 inches in a mile 63360÷102.7=616.94 rev/mile 63360÷99.4=637.42 rev/mile That's 3.21% different 425.8÷22.3=20.3mpg 20.3 at 3.21% should be around 19.65 mpg But I suck at math, so...- trreed's upgrade thread

That spring doesn't have to be lose, that tiny bearing I took out of mine was a bit wiggly, I think a guy could push that clip that holds spring farther in (even 1/4 inch will help) to get more tention on that bearing. It's just one of them one way clips, it will slide one way but not the other. But just in case get the bushing so if that clip falls appart then you can still fix it, lol.- Head gasket leaking oil

So you guys mentioned that you weren't sure on my spray pattern, what should it look like. Is mine too much timing and that's why you see it on outside of piston and not in the bowl. Or does it look normal.- trreed's upgrade thread

Did you look in to that rock solid bushing- Which injectors for compounds?

Man that's what I just put in is 75hp 8 hole, I know when I got the truck thats what I had in there, then I put 7 hole 60hp in and noticed more smoke and less power. Not by much but did notice it. I was trying for eliminate my surging problem on hwy when towing and that was a part of the reason I changed injectors, it seemed to help but then it came back and that's when I rebuilt the alternator and been good ever since. If my surging come back then I'll know for sure it's these injectors. I thought 8 holes burn cleaner.- PCM repair

You might have something cooked in side PCM after all. It could be something as simple as a resistor. Don't know if it's hard to open and look for obvious burnt parts, may worth a try. I just fixed a 95 suburban, ac wasn't getting as cold as it should and pressure was good in system. Ended up being a vacuum solenoid that shuts a valve to heater core, but it wasn't a solenoid it wasn't getting power. Traced down to control on the dash, it wasn't putting out juce. Ended up being a resistor in control board. I think it was 3.8 ohms I didn't have one so there are 3 at 1.2 total of 3.6 but it works now. Could be something similar with you.- A/C issues

To be honest I don't know on these trucks, but on several cars I fixed ac, you'd have orings at each connection. To condenser, to evaporator, maybe accumulator could be oring on any sensor, and I believe there is more than one maybe 3. Freon isn't too expensive, if you get the vacuum pump with kit so you can vacuum your self and not pay anyone then I wouldn't worry about changing compressor or any major components, I'd try research where all the conections are and change just orings to begin with, on sensors too. And you can maybe use a meter and make sure they work, and they should since your ac works fine just leaks out. You can buy an assortment of orings from part store probably. How long did it work before it quit. I'm using some stop leak in a car I drive been working all summer, but it's a 1500 dollar car too so, probably should fix it right.- PCM repair

It almost sounds as you may have a lose ground somewhere - Head gasket leaking oil