Everything posted by Cowboy

-

The Rise of the Shawty

I bought it as a rcsb. Yours must be a blast to drive being 4x4 I bet theirs not much on the street that can touch it.

-

2000 47 re

That is correct, do you know if they’re are any adapting options for that? Or are you stuck not using it?

-

2000 47 re

Yep they are the same.

-

Explain to me how the 47re shifts

The easy way is to buy a manual valve body kit from Transco, it’s gonna include the new valves and springs you need to both convert your trans to full manual as well as bump your pressures up to help your trans hold power.

-

The Rise of the Shawty

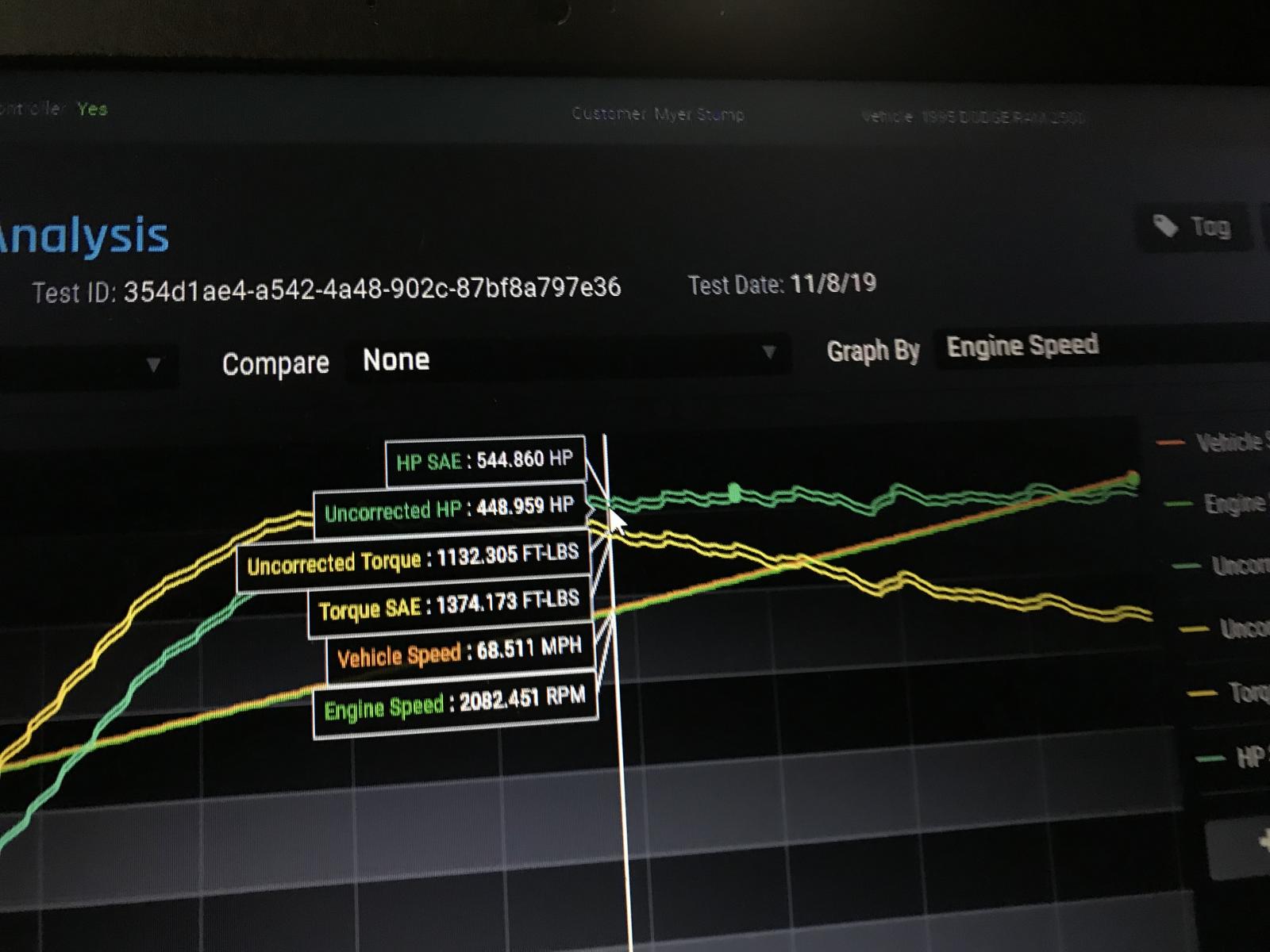

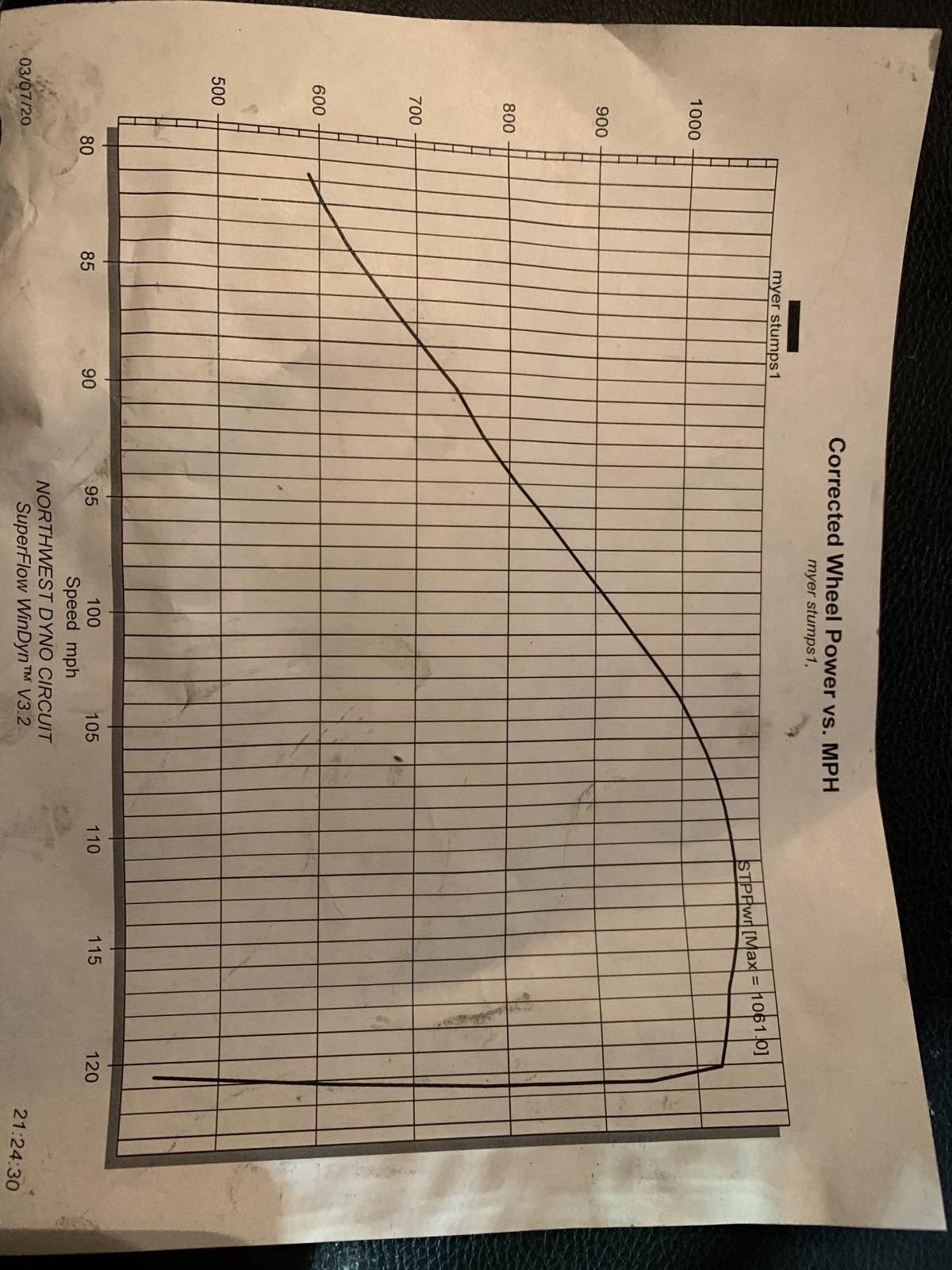

Howdy guys, it’s been some time since I was at all active online, but hopped on to see what was new and figured I’d let y’all know my current project. About a year ago I bought the shawty, it’s a 1995 rcsb. did the basic round of mods, maxed 180 pump, injectors, a s362, and a transmission that could hold it. Did 540hp on that setup that setup was a blast to daily drive, but I wanted to play with something new, so I decided to common rail swap it with some pretty good size wirly boiz all this was done in a rush to try and make it to the ATS gauntlet challenge, first fire was a week before the competition. I am glad to say we made it there! Overall made way more power than I was expecting to, I was 30hp away from the winner of my class at 1061hp. I found out later my boost controller was defective so it was fully opening the gate by 35psi so it wasn’t quite ideal, and put me down on power. I’m still tinkering on it, trying to squeeze a little more out of it, but hope to be above 1200 by the next time Northwest Dyno Circuit has another competition. Ive been dailying this thing to work every day, and can confirm it is a blast to drive. IMG_1593.MOV

-

Low boost overfueling

are you sure you're not lugging the engine down a little and then applying throttle? On mine, below 600 RPM the governor arm will slide under the AFC foot and allow full fuel, and will get stuck there for a second until the RPM's rise. Nothing unsafe or scary about it but it does belch out smoke unintentionally.

-

97 12 valve possible 05 turbo install

300 can be had with the stock turbo easily. Honestly, a little pump tuning on a stock engine will just about do it. and honest 350hp is all the stocker is good for, that he351 will help take it to the 400-425hp area. The HE351 didn't seem to have as much scooch below 1600 as the HX35, but after 1700 RPM it's pretty wicked. The swap can be done pretty easily, just drill out the 2 threaded holes in the exhaust flange, a downpipe adapter, and then a 2.75" to 3" 45° boot for the intake. You will have to pull the housings off so you can remove the alignment pins out so you can clock the housings.

-

trreed's upgrade thread

This is how they're plumbed. And this is kinda a crude drawing of the advantage of compounds. Red is a small turbo, Blue is a large turbo, and purple are compounds. You can see that the compounds don't spool quite as well as the secondary (small turbo) and don't flow quite as well as the primary (large turbo), but the broad RPM band and being able to keep the turbos in there efficiency range is the advantage.

-

Lets see who you are!

-

Tire balance

I've always used the chart from http://www.innovativebalancing.com I've done a couple dozen with the .177 BB's you get from walmart and don't have any complaints.

-

leaky brake booster

Here yar.

-

95 12 valve busted gear case

17-22 psi idling, 25-35 psi @ 2500 RPM no load is the spec. I got mine at 35-40psi because it gives me the warm and fuzzies.

-

95 12 valve busted gear case

These diesels can rattle a house down. The pins job is to keep the timing case 'centered' on the block, due to the injection pump and vacuum pump being bolted to the case, if it shifts, the gears will no longer be in alignment with the cam gear which drives them. Because of all the weight hanging off the case with a 50lb injection pump and the engine vibration, it's not unlikely. The handful of bolts holding the timing case to the block are also known for backing off due to engine vibration. So it's a good idea to take them out one by one and red locktite them.

-

95 12 valve busted gear case

I'd get a new pin, It keeps all the gears aligned properly. '95's came stock with vacuum boost brakes. The connection should be here.

-

No 4wd

This may help as well:

-

EGT's after the turbo

I have to agree with you John on many points. A part in me really wanted to get all technical about a formula for calculating the post turbine temps. But after reading your last couple posts, reality hit me like a brick and I realized no one is going to grab a calculator while pulling a hill to find if there temps are acceptable. And likewise, no one is watching their boost gauge at 5 psi like in my previous example. So I did a little datalogging while bringin' in the hay the last couple days. Nothing scientific, hard to get nice smooth data on gravel roads. Here's one graph, the X axis is time in seconds. Towards the end of the pull, Pre-EGT's are at 1415, while Post-EGT's are at 981. That makes for a delta temp of 434°F. Boost stayed pretty steady at 35 psi so that's 12.4 Degrees per PSI. And again: At 31.4 seconds: Pre-EGT = 1202°F Post-EGT = 830°F Delta = 372°F Boost ~27.2 psi Degree per PSI = 13.6 And one more. I shifted down this time to try and get the revs a little higher for increased drive pressure. At 14.8 seconds: Pre-EGT = 1147°F Post-EGT = 789°F Delta = 358°F Boost ~25.2 psi Degree per PSI = 14.2 So overall 10°F per psi boost is pretty close. Especially when you're swagging at it with a general rule of thumb. The number does seem to go up with RPM slightly, which makes sense due to increased drive pressure. On "measuring the temperature of the flame coming out of the head" I don't believe that to be necessarily accurate. Pre-turbine temps are 'artificially' (using the word loosely) inflated by drive pressure. Post-turbine temps better indicate the air to fuel ratio, when you're trying to make power at an RPM that the turbo isn't happy with, then it takes a lot more fuel to make the same amount of boost thus like you say John, Post temps can be out of hand, while pre-temps (which arn't being inflated much by drive pressure due to the lack of it), don't indicate anything as being wrong. As for my comment about turbine efficiency. I have always assumed that the inefficiency of the turbine adds heat to the exhaust just like the inefficiency of the compressor adds heat to the intake.... But. I just tried putting together a calculator for it assuming Adiabatic decompression, and well, either I fricked up somewhere, or that's not really the case. It will take more thought at a later date. EDIT: Quick test of my formula using it to calculate pre-IC temperatures puts it pretty accurate... I don't know anymore.

-

EGT's after the turbo

On a single-scroll turbine, I can see the 10° per psi rule of thumb being fairly accurate. But the efficiency curve of a twin-scroll housings are far more dynamic than a single scroll. And in the end, that is what determines pre vs post temps. When the pressure drops over the turbine housing, that causes a temperature drop. But just like the inefficiency of the compressor adds heat to the intake, the same goes for the turbine heating up the post turbine exhaust temps. As an example, I was pulling a grade yesterday, 850°F pre-temps & 650°F post-temps with 5 psi of boost. Another example, pulling a grade at 1900 RPM, 1140ºF Pre-temps & 780°F post temps with 20 psi of boost.

-

G56 Trans

Forgive me if I'm wrong. But Mercedes recommends a 50W fluid. The closest obtainable fluid to their spec is a Mobile Delvac 50 (SAE 50). However It's fairly thick and doesn't shift very well, especially cold. I'm personally thinking on trying a redline product. I'm currently running the CD-50. I've hauled 14k trailer weight running 65 mph and all sorts of other bullshitery and the highest I've seen was 160°F oil temp. At some point I'll be hauling a lot of weight at low speeds, I'm curious to see how it does then.

-

EGT's after the turbo

I did a little data collection as far as pre vs post turbine temps. This is on my 12V'er so your mileage may very. Not as scientific as it could be as the hills were short, and post turbine temps are heavily influenced by heat soak. 1680 RPM @ 860 Pre-EGT = 700 Post-EGT. 1875 RPM @ 1000 Pre-EGT = 740 Post-EGT. 2060 RPM @ 960 Pre-EGT = 720 Post-EGT. 2120 RPM @ 910 Pre-EGT = 710 Post-EGT. 2190 RPM @ 1050 Pre-EGT = 760 Post-EGT. 2240 RPM @ 1250 Pre-EGT = 840 Post-EGT. 2640 RPM @ 1040 Pre-EGT = 735 Post-EGT.

-

Ceramic Clutch

I buddy ran a cheap single ceramic he got off ebay for a while. When I pulled it out, it also had a 13" dual drilled flywheel with HD pilot bearing. So it's not necessarily from SB or Valair. I threw a 13" Organic in in its stead and he couldn't be happier.

-

EGT's after the turbo

Ehh yeah, but you don't get redneck point for that.

-

EGT's after the turbo

That's the idea yes, works like a charm.

-

EGT's after the turbo

You the man.

-

EGT's after the turbo

If you use the engine running method, you get extra redneck points for stuffing a piece of firewood in the exhaust pipe while doing it.

-

EGT's after the turbo

If I'm not mistaken, when cummins gave the 1200°F limit, it was for post turbo like all the big rigs are setup.