Everything posted by PilotHouse2500

-

Pilothouse/RAM3500 build

-

Last job I'll ever need...

sounds like a good gig!

-

Pilothouse/RAM3500 build

-

Pilothouse/RAM3500 build

-

Pilothouse/RAM3500 build

Another door I had laying around made the ultimate sacrifice yesterday (at one point I had 17 doors, got down to 6, will now be down to 2). I like how it's looking, trying to keep the "look" of the styling of the era.

-

Pilothouse/RAM3500 build

Video?

-

Pilothouse/RAM3500 build

No, I meant I was likely a few hundredths of a second from not being on this planet as a living being....if he had T-boned us at 60+ mph....I don't think I'd have made it.

-

Pilothouse/RAM3500 build

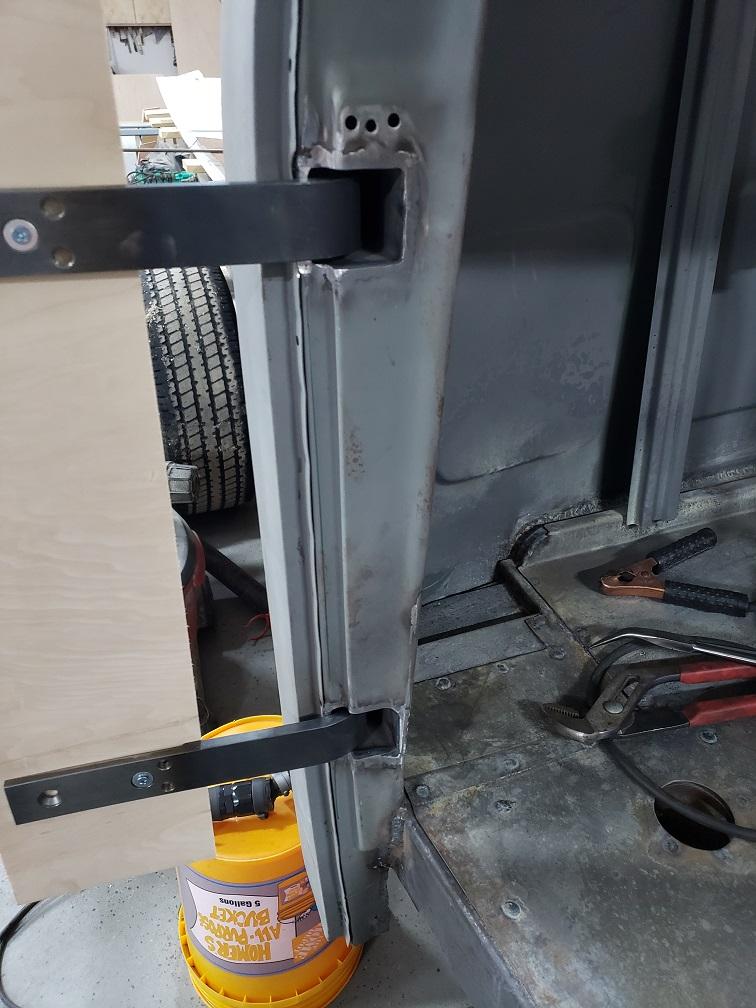

yah, I likely was a few hundreths of a second away from never posting here again... Meanwhile, first latch installed in the door, today I'll get the pin mounted and pray nothing locks up!

-

Pilothouse/RAM3500 build

been a while, but got some work done finally. What took 2 days should have taken a few hours....was in a highway speed accident lasy weekend where a guy blew his stop sign...not fun.

-

Pilothouse/RAM3500 build

Few steps further along. Thinking this is how the top "corner" will be. Gaps will all have to be "normailzed" with weld wire welded to the door edges at some point. Next steps will be to skin the doors and build up the inside.

-

Pilothouse/RAM3500 build

-

Pilothouse/RAM3500 build

Top infill panel all in, just need to finish it with a piece of 1/8" weld rod on the top edge. I know several here have said make the seam vertical, but that just does not go with the styling of the cab, so pointy bit it will be.....trust me.

-

Pilothouse/RAM3500 build

-

Pilothouse/RAM3500 build

Yah it was just being held in place with my left hand, eventually will be part of the read door. The pointy bit is currently WAY too pointy. The whole things needs to be gapped properly, but as proof of concept it'll work...I'll likely change my mind 4 times before I really settle. I'm still leaning towards a pointy type bit but blunt it a bit. Know that that is about 6'8" in the air....so not as worried about spearing myself on it as much as it getting damaged thru an "oops" moment. Other thought is to possibly make a small section live on the top sill and fill in a inch or so down between the 2 doors (making more 90 degree type joints), but it adds a few more body lines and gaps I'm trying to avoid (too busy).

-

Pilothouse/RAM3500 build

-

Pilothouse/RAM3500 build

thanks....the plan of the front part going on last night looks more like this weekend....lots to do to get there.

-

Pilothouse/RAM3500 build

I HOPE to have the front of the rear door put on tonight so it will be more obvious. Sealing these might be....interesting....

-

Pilothouse/RAM3500 build

-

Pilothouse/RAM3500 build

Well, the door "sill" beam that runs across the side of the cab is a 2 x 4 x 3/16 piece of tubular steel, and the rear cross tie is 2 x 2 x 1/4 tubular steel. The cab mounts are welded thoroughly to these members....if I get broadsided I think I'll be in pretty good shape except for NO crumple zones....PLUS I plan on schedule 40 pipes to be bent and made as the running board main frame. not fer sale! LOL. But I hope to do some serious road tripping before the morons make fuel unavailable and a loop thru the PNW on the way to my buddies in CA is on the list.

-

Pilothouse/RAM3500 build

Yah you have to open the front to open the rear. The straight line up just doesn't seem like a 50's era look, hence the pointy.

-

Pilothouse/RAM3500 build

The rear door will have a pointy bit towards the front, basically filling in the open spaces.....don't feel bad...its been a point I've struggled with: do I just run a vertical line up (like modern) or go for it all and do the pointy bit (full coach style build).

-

Pilothouse/RAM3500 build

Think modern vehicles with the suicide rear door with bearclaw top and bottom. Once both doors are open, no middle pillar. Next step is to build the rear door on the passenger side....I'll update as things progress.

-

Pilothouse/RAM3500 build

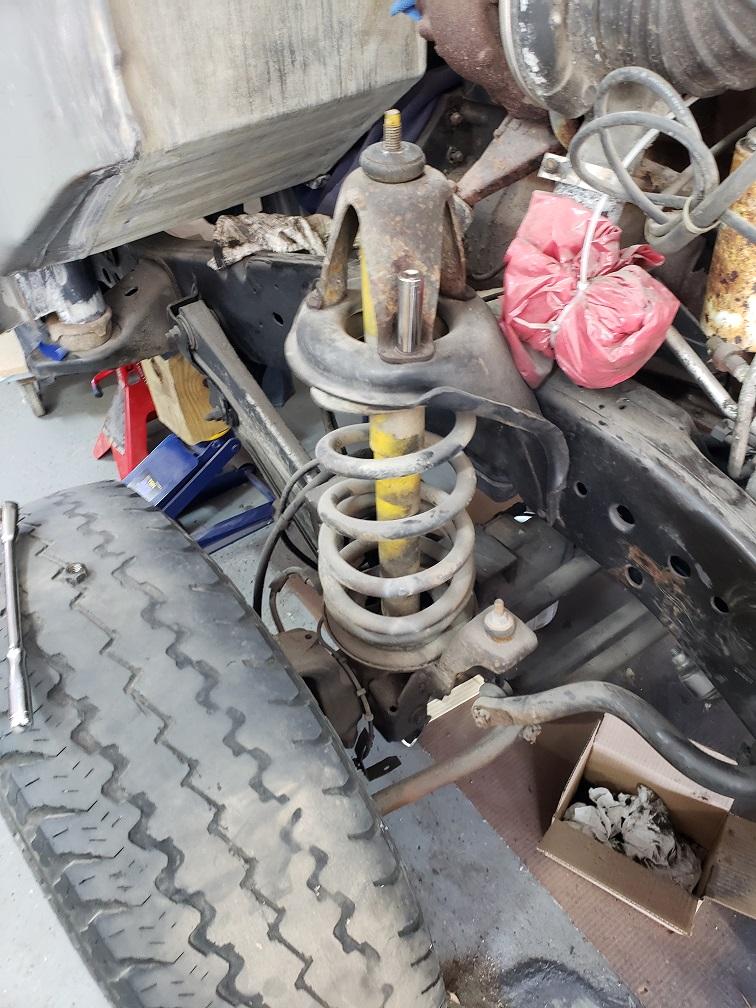

Actually Kelderman makes a complete kit for the rear....plug and play and tested for safety/workability. Replaces the springs and all. Some things I'll just pay for. I little door work going on to get it where it needs to be.

-

Pilothouse/RAM3500 build

yah $1500 for the fronts and when I can afford the rears at $3500...but seeing as I won't be hauling much weight much of the time, it will smooth the ride out and be less like a farm wagon.

-

Pilothouse/RAM3500 build