Everything posted by leathermaneod

-

Snubber, needle valve, or both?

Yes I tighten mine the same way and I can relate to your feeling of apprehension. On top of that it's hard to even get those fittings started because of the pressure of the rubber hose trying to twist it a different direction and I can't get two hands on it lol. That may be the cause of my leak. It's also really annoying to get two wrenches on those things because of the limited space. It is especially difficult for me to pinpoint leaks because I have a tapped 90° at each end of my "Big Line". That way I could keep the test Schrader valve at the vp44 and have my gauge tap at the other end like I have pictures at the beginning of this thread. So all those extra joints make for a real pain when trying to find leaks.

-

Snubber, needle valve, or both?

I am hoping that's is just what is going on. That flanges are not sealing together correctly. Possibly because of dirt, or maybe they just didn't get seated right due to the tension on them from the hose between them. Because of the size and the way it bends, it's a little hard to get them on straight. Especially since it's so tight down there. That's also what makes it so hard to tell where it's coming from.

-

Snubber, needle valve, or both?

Oh ok. Yes all of mine are at least into the washer.

-

Snubber, needle valve, or both?

Yes I believe that is where the vp end is leaking. Hopefully that one just needs to be loosened and re tightened or taken off cleaned and re tightened. With the filter housing end though, I checked and checked and felt all over and it really seems like that's not it. But I'm going to try it anyway. I have to wait for warmer weather again now and I may have to wait on a new piece of hose too. I'll let you guys know when I figure it out. i was just thinking, I guess it's possible that it's not on far enough? There's more than one of my push lock fitting that didn't go on quite right enough to make that plastic washer tight. I didn't think that was an issue though....never had a leak anywhere else...

-

Snubber, needle valve, or both?

Lol nice. I haven't done that many, but I found that heating the ends with a small propane torch works pretty good. The odd thing with this situation is that it didn't leak before. I took the whole 18" long filter to vp hose off the truck to add the needle valve and now I'm having issues. The stupid thing should not be than sensitive imo. Now I can't play with my new toy till I get the darn thing fixed again. I have to put new brakes on my wife's crv tomorrow so after that I'm going to try popping each end off and make sure there's no dirt on the mating surfaces an then tighten them back up and see what happens. Provided it's not 25° with 20mph winds. I'm 99% sure the filter end has fuel coming right out the end of the hose, but it is very hard to see down there so maybe I'm wrong. I'm also going to call Vulcan and see if they've heard of anything like this and see if they will send me a new piece of hose since it was their big line kit.

-

Snubber, needle valve, or both?

That's kinda what I thought, but I was looking and feeling around and it really seems like it's coming out the end of the hose. It's def on all the way and it didn't leak before. However it is in a different position now and I did spray the brake cleaner through it as I said. So I'm not sure if those factors could have messed it up somehow. What do you mean about a bad push lock fitting though? Bad how?

-

Snubber, needle valve, or both?

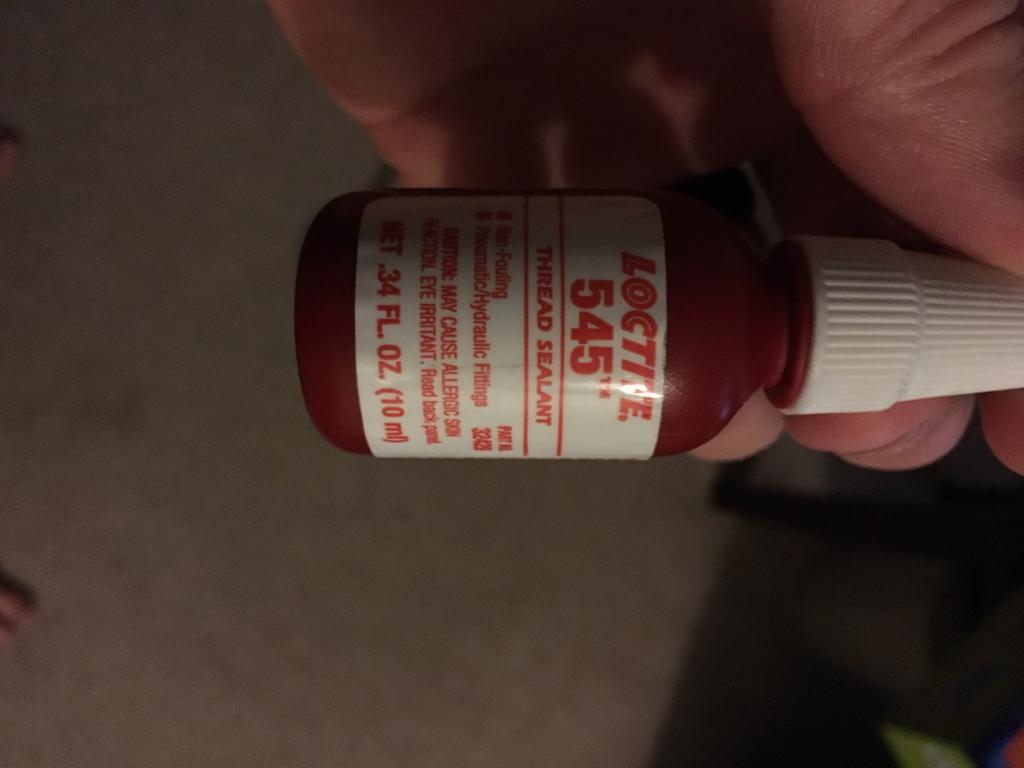

I don't have pipe dope on it anymore. When I did put it on I was extremely careful not to use very much and to keep it from getting on the inside. When it leaked with the pipe dope, I took it back off the truck and disassembled it all and cleaned everything with wire brush, brake cleaner, and compressed air. Then I put it back together with locktite 545, the purple stuff. I let it dry for at least 24 hrs, then reinstalled it. Now the problem is something is still leaking. But it really seems like the fuel is coming from the hose where it meets the fitting. Should I be getting a new piece of 1/2 push lock fuel hose? I thought pushlocks didn't leak? unless the brake cleaner degraded the hose? I didn't think that could happen either....

-

Snubber, needle valve, or both?

Thanks Katoom. I just got back from the first test ride with the comp all hooked up and i think its working fine. I am very impressed. The top end is AMAZING. I hit almost 2500 without even realizing it(thats pretty high for me). Unfortunately, when I got back I realized that I have an almost new belt that won't stop squeaking, and much worse, more fuel leaks. It really hard to tell exactly where its coming from, but it seems like its the push lock fitting that comes out of the bottom of my filter housing, not any of the fittings I just put together with 545. Maybe thats where it came from before when I did the pipe dope?...but can push lock fittings leak??? Its not that old, like less than 10k miles and like 6 or 8 months. Weird thing is, its also leaking from the other end at the VP, but that seems to be coming from the fitting itself, where the swivel nut part meets the body of the fitting. So hopefully that one just needs to be loosened and tightened again. I guess Ill try that for the other on too, but it really seems like its coming from where the hose meets the fitting...anyone ever had a push lock fitting just randomly start leaking? I did spray break cleaner in there to make sure there was not dirt from old pipe dope when I took it apart....could that have degraded the fuel hose??

-

Snubber, needle valve, or both?

Thanks for the call Mike! I really really appreciate your time and all your help. Plus its great to chat with a person who can teach me a think or two(or 100 lol) about these trucks!

-

Snubber, needle valve, or both?

Lol I wasn't shaking it, it was very obvious when moving it/turning it over ect. But ok sounds good. I will take your advice and see what happens. Probably nothing wrong with it, it just seemed odd to me. While we are on the subject, I have another question. I was looking at the parts and the instructions for the install and I saw they have a sweet fuse tap that is a 10 amp fuze with a wire soldered onto one leg. Now the instructions are very specific that the it should be used in place of the #9 fuse and the tap side of the fuze should be the HOT side. My question is, wouldn't that make the comp unfused and able to draw as much power as the truck will give it, possibly frying things?

-

Snubber, needle valve, or both?

Very interesting! Have you ever noticed anything like what I described with your comp box?

-

Snubber, needle valve, or both?

Really? Even ones with NPT threads? Also, random question. Finally got my edge comp today. I should have had it yesterday but they sent me an EZ. They got it taken care of very quickly though by overnighting me the comp without even waiting for me to send the EZ back. Anyway, when I first picked the comp box up, it kind of rattled like something was moving inside of it. I quickly realized that the plug port that comes out of the back moves somewhat in its hole(and whatever it is attached to inside). I made sure the screws were tight and they are. Is this normal? Or should I be calling edge again to swap it out?

-

Longer cranking...

The military or Ordnance style battery terminals are awesome!!! I needed new ends on my cables and switched to ordnance terminals. I also replaced my crossover cable(between the two batteries) with 2/0 cable and had the ends crimped on by the local tractor dealer where I got the cable.

-

Longer cranking...

If you are really worried about the batteries you can pop them out and take them to a place like autozone. They should have a load tester that will tell you if one or both are bad. Make sure you specify a load test though. I was fighting similar issues a while back and it was a combination of one bad battery and a weak starter. If you suspect it is your starter, you can pop the solenoid housing apart to check the contacts. Rebuild kits are readily available, that way you can keep the original rather than replacing it with a reman. Hope this helps!

-

Snubber, needle valve, or both?

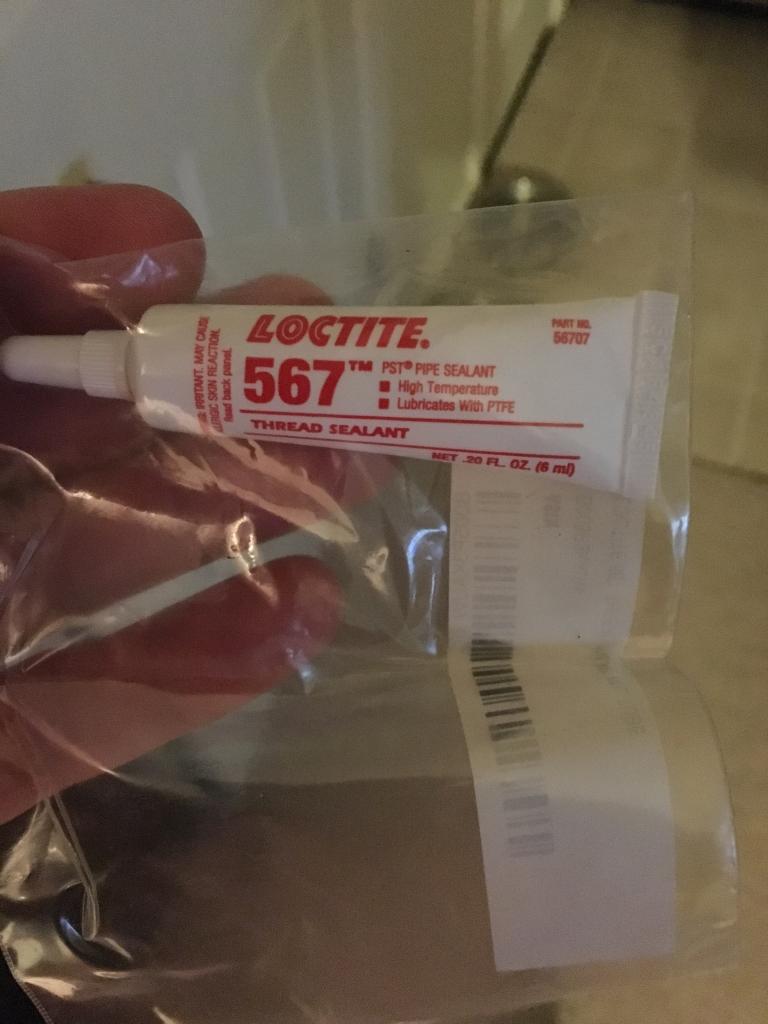

I did use it after the dope fail. I just liked the idea of the dope staying somewhat soft and pliable so that you can move it slightly. Where as the 545 gets rock hard and can't be moved once it's cured.

-

Snubber, needle valve, or both?

Dont you guys find the Teflon tape a pain to work with on such small fitting? I mean there ends up being a lot of extra even on air hose fittings. And what's the difference between yellow and white? I actually did not check to see if it was compatible with petroleum. I bought the stuff when I installed my Fuel Boss because it's what Rich at GDP recomended. I just made sure that it was PTFE because that is what he specified and I have had no problems with it. I used it on the 3/8 fittings where they thread into the pump. I'm guessing there just wasn't enough of it on these tiny fittings.

-

Snubber, needle valve, or both?

Edit: just wanted to say that my post above is not meant to offend anyone who mentioned pipe dope and I do not want to sound ungrateful for anyone's input. I was just a little annoyed with my leaks when a wrote it lol so I decided to get that stuff back apart right away while the weather is still nice. When I took everything apart I noticed that it literally looked like the fuel was dissolving the pipe dope. I got it cleaned up and back together with the 545. That stuff is great to work with btw! Had forgotten how nice it is. I didn't re install it yet though because the bottle says it fully cures in 24hrs. Since I have time I decided to wait and be safe. I also forgot to mention earlier earlier that I changed my fuel filter at the same time. Went from a Baldwin pf7777 to a 7977. I also removed my fuel filter canister and cleaned it. It had a TON of sediment in the bottom! I tried to remove the fuel heater but it didn't come out easily and I couldn't find instructions so the whole thing got hosed out with brake cleaner and then compressed air. Then I used a rag on a screwdriver to reach all the way in the bottom to get the stuck on stuff. Is the fuel heater connector supposed to have some kind of gasket where it mounts to the housing? Mine doesn't and it has a decent gap on the bottom where dirt can get in to where the wires are...

-

Snubber, needle valve, or both?

Well after my experience today I can not recomend regular pipe dope to anyone. I'm not sure why, if I didn't have enough or what, but I redid everything I had pictured plus the Schrader valve in the tapped 90 at the other end and I have multiple leaks. Like I said I'm not sure why, I didn't use a lot because I was trying to be very careful not to get any on the inside, but I did use plenty. Maybe it's just because the fittings are so small. So now next time the weather is nice I've got to tear it apart again. I guess I should have just used the 545 to begin with, but I like the idea of pipe dope staying somewhat pliable, where the 545 gets very hard. Anyway just figured I'd throw this out there as a caution.

-

Snubber, needle valve, or both?

Wow thanks for all the replies! Those of you that said you like the 545, how long do you wait for it to dry before running fuel through the system?

-

Snubber, needle valve, or both?

Thanks for the tips! I hadn't thought of Teflon tape. You think that's safe to use in a situation where there is no filter between it and the injectors? I thought I had read of guys having trouble with pieces of it breaking off inside though...I guess it should be ok if I keep it back a few threads...

-

Snubber, needle valve, or both?

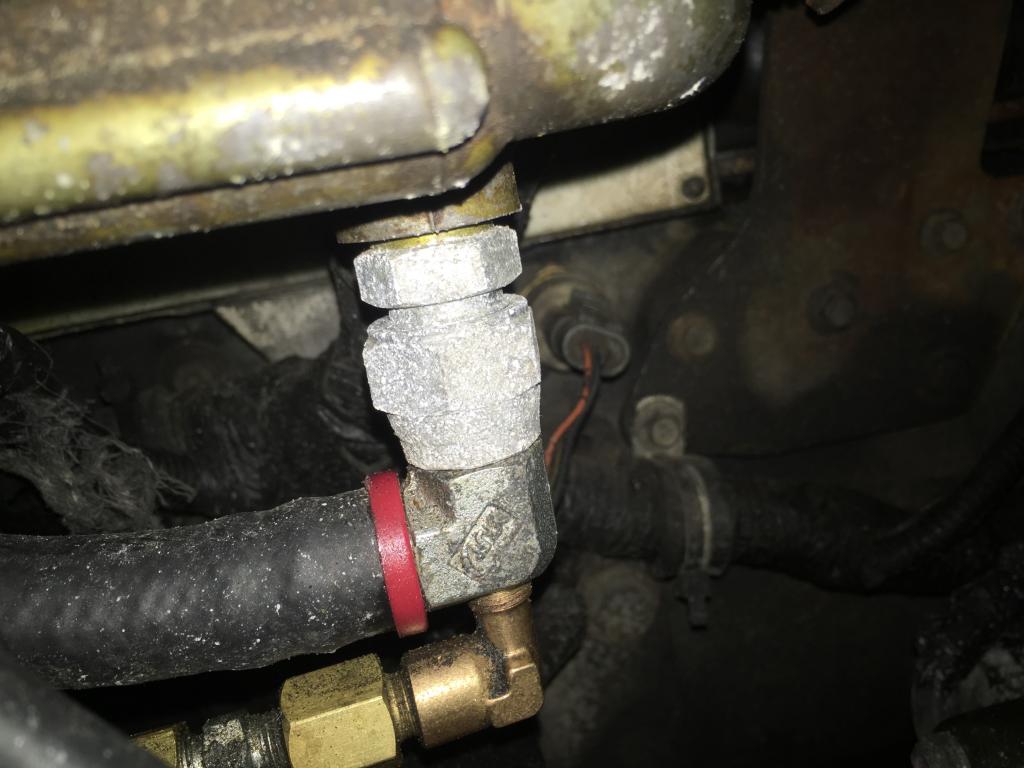

Hi all, So shortly after getting my Fuel Boss lift pump and big line kit installed a few months ago I noticed that I have a 1-2 psi needle bounce in my autometer mechanical fuel pressure gauge. I am using a snubber from Geno's and my pressure tap is located on the filter canister outlet. As you can see here. The items are from left to right, Female JIC end of Vulcan Universal Fuel line(brass), Male JIC to NPT adapter(silver), Geno's snubber(brass), Street 90 from Ace(brass). This setup comes out of the tapped 90 that attaches to the bottom of the fuel filter canister. Anyway, I've dealt with the needle bounce for this long, but I always regretted not installing a needle valve so that I could turn the gauge supply off in an emergency. The more I thought about it, I realized that adding a needle valve would probably help with my needle bounce and make my gauge last longer. So I got one from Vulcan. My question is, should I used the snubber and the needle valve? or just the needle valve? The only thing that concerns me about using both is that assembly is getting long and heavy where it comes out of that tapped 90. Also, does it matter what order I put the items in? I am also looking for recommendations on thread sealant for the NPT threads. I have used this and this in the past and both seem to be ok. The 545 is the purple liquid stuff and I always feel like I need to let it sit overnight before running fuel through it. The 567 is more like regular pipe dope. I always figured the purple liquid stuff was safer for a post filter application than pipe dope just incase some got to the injectors. But I was told when I did my Fuel Boss install that regular white(PTFE or whatever its called) pipe dope was fine for that. I would like to know what you all think and normally use. Thanks in advance!

-

Having trouble getting my Scanguage calibrated

Gotcha! Yes I know the space is limited, but I figured without removing the pump, it's as good as its gona get the way it is. But if/when I am removing the pump, I'd like to fix it as well as possible and solder the wires, then use adhesive lined heat shrink tube. I was just concerned that the heat from soldering could damage the vp's electronics since it will be so close to where the wire goes in there. This would also be a case where it is critical to use solder that does not have acid correct? I guess it's time to start getting all the parts together for doing the vac pump. And all the other little odds and ends to do at the same time. Hopefully I don't have so much trouble with injector line leaks this time. Although maybe if I remove the intake horn and vp plug and all that ill be able to fix all that without removing the pump. Guess I'll have to wait and see.

-

Having trouble getting my Scanguage calibrated

Well I may just do that sometime soon then. Is there a reason not to solder the wires? Or why so keen on the heat shrink butt connectors? I mean I like them too but isn't soldering better? Since we're on the subject, what do I need to know for pulling the vp? I know about not loosing the little key, but how do I get it pointed up? Is there a good way to keep it from falling out when I'm reinstalling? Is there anything else I should do to the vp while its out like tighten the deliver valves or anything? Maybe I'll pull the vacuum and power steering pumps while the vp is out to rebuild the vac. Having the vp out should make that job easier. Once all that's done I can just get the stealth plate. Does that need to be installed with the vp off?

-

Having trouble getting my Scanguage calibrated

You mean that's what you would do to fix it properly? Or that's what you would have done to begin with? I would have used them to begin with if it was me, or if I thought I had room solder and heat shrink. I'm pretty sure I can't do either at this point without removing the vp. Just not enough room in there. I think that liquid tape will hold up for a good long time though. And there's no reason, in my opinion, that a crimped connector like that should fail as long as it's protected, which, with the liquid tape it is. maybe I could do it if I unplugged the vp connector, idk if it's worth messing with though...

-

Having trouble getting my Scanguage calibrated

I have seen those and I would definitely go that route except for the fact that my pump wire was tapped in the past. One of the PO's cut the wire and spiced in a little bit longer loop. He also added an extra leg out one of the butt connectors to make it easy to connect to. Shortly after I bought the truck, a place that did some work to the truck for me, cut that wire off way to short to do anything with other than crimp a cap on so that it wouldnt short against anything. Until now I had no plans to ever tap the pump and I almost cut that mess off to fix it all correctly with solder and adhesive lined heat shrink. But as I was getting ready to do it, I decided as long as everything works just fine, it wasn't worth messing with and risking ruining the pump or at least having to remove it to get more space. So I just liquid tapped all the ends of the connectors to protect them from moisture. Sometime in the future I will remove the pump and fix it right, but until then a regular wire tap will be fine and save me the $70. this is what it looked like this is how I "fixed" it. I know its a mess, but hopefully it works for a good long time.