Everything posted by Rogan

-

Power of words - Must see video

she's hot.Oh, the sign was perfect..

-

Cold start and block heater

agreed.

-

Little squeak

No doubt

-

"built" 47RE woes

maybe so, john.. but a sound-board would be nice, once in awhile! lolyou know, to bounce ideas off of?

-

Cold start and block heater

It would be nice, but no, they aren't. It's heating as long as it has AC power plugged into it.. This is why I use a timer to turn power on to my extension cord at a preset time... Mine is set to come on about 6am, as I generally leave the house around 700-730am. My timer is an inexpensive 15amp timer from True Value Hardware.. http://www.truevalue.com/product/15A1250W-Black-Outdoor-Heavy-Duty-Mechanical-Timer/3436.uts?refineByCategoryName=Lighting&keyword=timer

-

"built" 47RE woes

can any of you with 12V autos verify what yours may read under same conditions? - - - Updated - - - So I did a little transmission testing after I got home from work.. I disconnected the tv cable from the trans side.. I then took a piece of lace wire and tied the tv arm (on the trans) to about 1/2-3/4 position and took the truck for a spin. WOW! What a different truck to drive.. 1-2 shift occurs around 10mph, and 2-3 around 25-30mph. More so, both occur around 2000-2100rpm. They are VERY POSITIVE shifts (as to be expected with a "built trans") and the truck flat-out flies. It pulls extremely hard with about 50-75% throttle positions.. You can even feel a positive down-shift when slowing to a stop, etc., rather than feeling just.. well.. mushy.. So, I think the main issue may be a pressure control problem in the tv cable and/or it's operation. I've already tried to adjust it (previously) to no avail.. So now I need to concentrate on that aspect of the transmission issue.. Additionally, with the tv cable disco'd, the throttle response (and ease of pedal travel) is a lot better/easier. The truck pegged 25-30psi easily, as well, which it never did before. - - - Updated - - - I have to say, that I am totally amazed that this thread has gotten very little response and/or input from you guys.. I'm not bitchin, more so just surprised..

-

Brand of tires?

frictional tension.Friends of mine own and live on a campground. From the hard-surface main road, back to their office and houses is about 2miles-ish of gravel/shale. They go through tires about every couple of years, mostly due to cuts and such..

-

Cold start and block heater

would "cold wind" even be a factor, since that air is no colder than the actual temperatures? (i mean, wind chill has no bearing on inanimate objects?I plug mine in, and use a timer, so it only is "powered" for about 1.5-2hrs before I leave for work..

-

Never judge a farm truck

awesome!

-

No turn signals

For starters, check FUSE 6 (20A). From there, pull the turn signal flasher and check for power (in ACC or RUN key position) at pin 2. **Note: Hazard and Turn signals use separate flasher circuits.. [*]Turn Signal circuit uses pins 1 & 2 [*]Hazard Flasher circuit uses pin 3 & 4 You can also swap the hazard flasher for the turn signal flasher to verify if one of the flashers may be bad. If that all checks out so far, then move to the turn signal switch (TSS).. Take off the column covers to access the connector section.. TSS should have 12V constant on pin13. Pin 17 should have 12V with key in ACC/RUN position. If that tests good, then let's move on to pin 14. This should see 12V when the brake pedal is depressed. With brake pedal depressed, you should also see 12V on pins 15 (Left Tail light, Dk GRN/RED) & 12 (Right Tail Light, BRN/PNK). These get flash circuit interruptions once the turn signal is activated for whichever given side, as the power then gets pulled from the flasher circuit for that given signal choice; the other brake light stays illuminated through the brake circuit above. If you have all these power inputs into the turn signal switch, but nothing coming out (turn signal-wise, then it's most-likely a switch issue.

-

Brand of tires?

driving habits, terrain, weather, and hard-surface composition definitely play a part in how long tires last. Additionally, and maybe more importantly, is the maintenance one may or may not do with tires (air pressure, rotations, alignment, etc.)I had DynaPro MT03s (305-75-16-E) on my truck for about a year, and put about 15k on them. They barely looked used at all..I stepped down in size (235-85-16-E) and went with Federal Couragia MTs. I put about 10K on them (under basically the same conditions) and they looked nearly worn out.Tire material/composition has a lot to do with how a tire wears.

-

What fuel pressure do you run if you have a gauge?

there's a fitting on the VP pump to test fuel pressure.. I replaced that banjo fitting with one designed to hold a FP sensor.

-

Fog light wiring

Is all good, mike! I'm a man of function over form.. Thanks!

- Red neck nascar

-

Fog light wiring

So snap me a pic of the m73m bracketry :)Sent from my SPH-L710 using Tapatalk 2

-

Brand of tires?

Touche'Sent from my SPH-L710 using Tapatalk 2

-

Brand of tires?

Not to sound like a @$%& or anything, but there's tons of threads here, already, talking about this very same thing

-

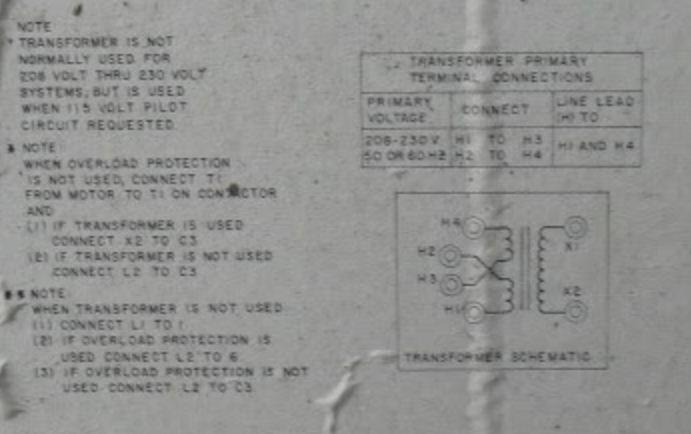

Anyone an electrician or inclined?

I think that's "K", rather than "x"...

-

Steering gear box

I haven't replaced mine, yet.. But I'm a firm believer of the 'if it ain't broke, don't fix it' routine. You can rebuild the PS pump and such for fairly cheap, and it isn't that huge of an under-taking.

-

Steering gear box

Borgeson Box if you're gonna replace it.. Spohn Performance has if for like $380-ish. It's ~$410 at Genos. So look and price around..PN# 800112 The new box is 13:1, vs 16:1 (3.5 turns L-to-L, vs. 4.5 turns L-to-L) so it's much more responsive.

-

Anyone an electrician or inclined?

NOTE: - transformer is not normally used for 208 VOLT thru 230 VOLT systems, but is used when 115 volt pilot circuit requested. NOTE - when overload protection is not used, connect t6 from motor to t1 on xonnector and (1) if transformer is used connect x3 to c3 (2) if transformer is not used connect L2 to C3 ##NOTE When transformer is not used (1)connect L1 to ... (2)If overload protection is used, connect L2 to 6.. (3)if overload protection is not used connect L2 to C3 [TABLE=class: outer_border, width: 400] [TR] [TD=align: center]TRANSFORMER PRIMARY TERMINAL CONNECTIONS [/TD] [/TR] [/TABLE] [TABLE=class: grid, width: 400] [TR] [TD]PRIMARY VOLTAGE [/TD] [TD]CONNECT [/TD] [TD]LINE LEAD (H) TO [/TD] [/TR] [TR] [TD]208-230V 60 or 60 HZ [/TD] [TD]H1 TO H3 H2 TO H4 [/TD] [TD]H1 and H4 [/TD] [/TR] [/TABLE]

-

Edge Comp Locked Up

The unfortunate of that is the older gens cannot quite take advantage of a true hex writer, like you can :(I ran open source tuning (hex programmer) on my Subaru and I will totally agree with you.. There's nothing like having the ability to do that, from a tuning perspective.

-

"built" 47RE woes

At idle in park.. 13.7% LOAD, 28.2% TPS.. Seems a little high for both, no? Pay no mind to the Coolant temp, as the 12V PCM/ECM doesn't read the coolant, only the gauge does. Sent from my SPH-L710 using Tapatalk 2

-

Transfer case blow up

My buddy's tcase in his 04 did it, too.. cruising down the highway in Alabama, on his way back to VA.

-

Edge Comp Locked Up

I wish my truck's problems were that easily rectified.. :banghead: