Everything posted by IBMobile

-

It's Getting Worse Out there......

I've driven with @JAG1and lived to talk about it. Sheeple, go along to get a long. Most are to busy with work and family to know more than the 30 seconds of skewed info from the alphabet soup news media. Critical thinking is not taught but the progressive doctrinarian is. I bet they can tell you the standing of their favorite sports team along with who the star players are but could not tell you who their state representative, senators, or 4 of the 9 supreme court justices are. On another note, just a short time ago McDonalds workers were crying out that the minimum wage was to low and the mantra became $15 an hour. After months of news stories of how a person couldn't feed their family on a work force entry level job wages, states raised there minimum wage level. This new round of the highest rate of inflation in 30 years is now wiping out those gains. Will the new minimum wage target be $20?

-

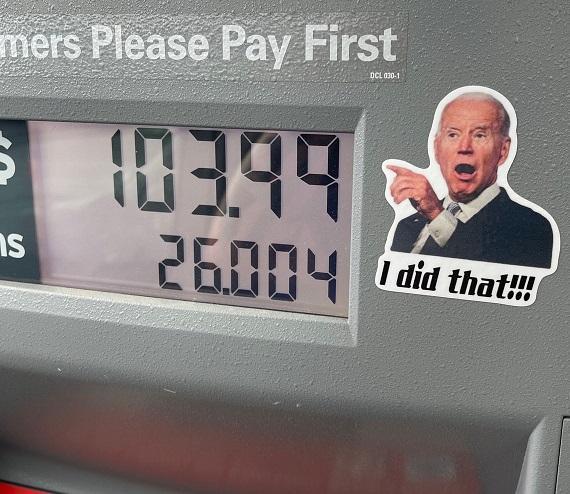

It's Getting Worse Out there......

BIDEN...the best reason to vote for someone else. You are not alone in seeing this. There have been several articles written about the books' interpretation. This is one view: https://www.linkedin.com/pulse/we-living-1984-chilling-reality-how-todays-world-big-otterburn-hall

-

Post Mod Trans Issue

This is true. The Government will always need a supply of petroleum jelly, IE: Vaseline, to help ease the pain when they're sticking it to you. This is your Government caring for you.

-

Belt Tensioner Life Span

Use to have a chirp every time the engine was shut off. I replaced the belt with a Goodyear Gatorback belt, 4080652, no more noise.

-

Rear door mechanism adjustment

Can you get one from a pick your part type yard? That's where I got three of them last year. The cable, part #55275106, is the same whether 1500, 2500, or 3500; left or right. I have a commercial account with O'Reilly auto parts and try to deal with one older associate at the commercial desk. The prices are not cheap and still get the wrong parts. At lest he doesn't ask me if I would like fries with that.

-

It's Getting Worse Out there......

No, only watch him at his regular time on Fox News. It would have shown him coming up from behind on the side and that you stayed in your lane. EXTRA EXTRA The airports and border crossings are now open to international travelers and can come into the country so long as they show proof of covid-19 vaccination. I guess all those people streaming across our southern boarder aren't considered international travelers.

-

It's Getting Worse Out there......

Hillsdale College is having a free live streaming lecture series listed below. To watch go to You Tube and type in Hillsdale College The Great Reset. It's free . Sunday, November 7 4:00 p.m. ET “What Is the Great Reset?” Michael Rectenwald Author, Beyond Woke 8:00 p.m. ET “Woke Capitalism vs. Profit” Vivek Ramaswamy Author, Woke, Inc.: Inside Corporate America’s Social Justice Scam ______ Monday, November 8 4:00 p.m. ET “Cashless Society” James Rickards Author, The New Great Depression: Winners and Losers in a Post-Pandemic World 8:00 p.m. ET “Is ‘Environmental Justice’ Good for the Environment?” Mark P. Mills Manhattan Institute ______ Tuesday, November 9 4:00 p.m. ET “The Great Reset from China’s Perspective” David P. Goldman Asia Times 8:00 p.m. ET “The Alternative to the Great Reset” Brian Wesbury First Trust Advisors Watch the Livestream

-

It's Getting Worse Out there......

Two words DASH CAM. Get a dash cam that records both front and back so when the next model driver exhibits their fancy driving moves near you there will be a video record of it. You've seen the one in my truck. You got your big "hand out". The government gave you your big hand out in the form of "CORONAVIRUS STIMULUS CHECKS". You should have received 3 checks for a grand total of $3,200. I hope you didn't spend it all in on place like I did. These things are no longer taught in the schools. History is not written in stone but rather "history is written by the victors" ¹. Todays students are not taught the hardships and sacrifices the founding fathers, immigrants, citizens, soldiers made so they can enjoy their freedom from tyranny. But yet, tyranny has been slowly dismantling this society over the last 100 years till "Freedom is never more than one generation away from extinction"². Our freedoms have been slowly given up for "safety". A prime example is The TSA and airport security. This is Kabuki theater at its finest with more showmen ship than content. Is that 78 year old lady from Denmark really a terrorist or just wants to see her grandson? These mandates are being used to see who will go along with the government and who will resist. Some people will go along because they believe the propaganda, others because it is easier to go along than to resist and the last group will do it to keep what they have or get something they want. Those that resist, as we have seen, will be ostracized from society by needing a vaccine passport and marked unclean like the lepers in the Bible. When someone asks me " have you been vaccinated" my reply is a firm yes. They didn't ask me which vaccination though; small pox and polio ¹Winston Churchill ²Ronald Reagan

-

Post Mod Trans Issue

I had Dynamic build a "Stage 2" transmission with a Goeren triple disc torque convertor and an upgraded flex plate. The input shaft was not changed out. Before that I had a local guy build my trans with a single disc convertor that didn't last 40k.

-

Oil Cap/valve cover gasket size?

You can only get the seal with a new cap. Dodge # 05014704AB Stant #10111 Gates #31118

-

Lost Brakes and Power Steering on First Cold Morning 01 Ram 2500 Auto

Here it is in the 12 valve articles. https://mopar1973man.com/cummins/articles.html/12-valve-2nd-generation/axles-suspension-brakes/diy-hotrod-power-steering-pump-r381/

-

Head studs

to replace the injectors watch this video. https://mopar1973man.com/cummins/articles.html/24-valve-2nd-generation_50/51_engine/59_fuel/injector-install-video-r16/ To replace the valve springs watch this video. you can pull the push rods out and replace them when doing the valve springs.

-

Alternator stopped charging

JB Weld would fix that.

-

New tps issues

I did the same as @Threadzywith no problems. This may help you understand how the transmission shifts. From @Dynamic 11/6/2015 You basically have two different pressures at work in the VB when determining upshift and downshift points. First, there is governor pressure, which is determined by road speed. Early transmissions (46RH, 47RH) used a mechanical governor on the output shaft, and the newer RE transmissions replaced the mechanical governor with the governor pressure solenoid/transducer setup that we all know and love. The PCM generates the governor pressure electrically via the solenoid, and monitors the governor pressure via the transducer. Either way, the faster you are driving, the more governor pressure... Second, you have throttle valve, or TV pressure. This pressure is determined by throttle position. When you press on the throttle, the TV cable pulls on the lever at the transmission, which rotates the TV lever shaft, which then presses on the end of the TV plunger in the VB. The plunger then loads the TV pressure regulator spring more heavily which, in turn, increases TV pressure; the more throttle, the more TV pressure... There are two shift valves in the VB that use governor and TV pressure to determine shift points; the 1-2, and the 2-3 shift valves. (The 3-4 shift valve and TCC lockup valve are controlled separately by the PCM via solenoids and do not use governor or TV pressure to determine their shift points.) At each shift valve, governor pressure acts on one end of the valve, constantly trying to stroke the valve to the "upshifted" position. At the other end, there is a spring holding the valve in the "downshifted" position. In addition to the spring, TV pressure also acts on that same end of the valve, assisting the spring in holding the valve in the "downshifted" position. When you are at a standstill, governor pressure is at a minimum (basically zero psi) and the shift springs hold their valves in the "downshifted" position - first gear. As you take off from a stop, governor pressure begins to rise, acting on the end of the shift valves. If you are light on the throttle, TV pressure is very low and governor pressure quickly rises to the point that the force of the 1-2 shift spring at the other end of the valve is overcome and the 1-2 shift valve strokes, commanding a 1-2 upshift. The transmission is now in 2nd gear... If you are heavier into the throttle, TV pressure assists the spring with greater force, making it necessary for governor pressure to build to a higher level before the force of the spring AND the hydraulic force of the TV pressure acting on the end of the valve to be overcome. This is how the transmission holds each gear for longer when you are heavier into the throttle. As you continue to accelerate, governor pressure continues to rise until the 2-3 spring force (and whatever level of TV pressure that is acting on the 2-3 shift valve) is overcome and the 2-3 shift valve strokes, commanding a 2-3 upshift - 3rd gear... When commanding a downshift, you press on the throttle harder and TV pressure rises. When TV pressure rises to the point that (with the spring's help) governor pressure can be overcome, the valve will stroke back to the "downshifted" position and either a 3-2 or 2-1 downshift is commanded, depending upon which gear you were in. If the throttle application is abrupt enough, and TV pressure rises quickly enough, both valves will be stroked to the "downshifted" position nearly simultaneously, and a 3-1 downshift will occur. This is kind of a simplified explanation of what goes on in the Dodge valve body for 1st - 3rd gear. As I stated earlier, 4th gear (OverDrive) and TCC are controlled directly by the PCM via their respective solenoids.

-

New tps issues

A bad TPS can cause a delayed or no 3-4 up shift, no 4-3 down shift, or a 3-4 upshift immediately after the 2-3 up shift. The 1-2 shift problem can be valve body/kick down cable or governor circuit electrical fault. Check the trans fluid level and condition along with the kick down cable adjustment and swap the transmission relay with the horn relay in the PDC to start with. If you're going to replace your TPS use a "Timbos" apps. They are better than the factory part and not made in China like the ones you see being sold for $25-$50. Those cheap ones can give you a head ache. Try adjusting the TPS/APPS the way the article below shows it. You may want to try it with your old TPS also. https://mopar1973man.com/cummins/articles.html/24-valve-2nd-generation_50/51_engine/electrical/stock-apps-sensor-voltage-adjustment-r34/

-

Alternator stopped charging

It was a cold morning at the campground, 24°F, so before starting the truck's engine I flipped the switch to cancel the grid heater bypass and let them do their thing. After the grid heaters cycled the engine was started just fine with all the gauges coming alive. Once the oil reached safe operating pressure I flipped the switch which turns on the onboard air compressor for the exhaust brake. It was now time to get the show on the road and shift to drive; what the, "check engine" light is on. I pull out my handy dandy code reader an get this: P0753 Transmission 3-4 Shift Solenoid / Transmission Relay Circuits P1765 Transmission 12-Volt Supply Relay Control Circuit P1682 Charging System Voltage Too Low The "check gauges" light pops on and the dash volt meter is not reading. With a multimeter I see that the voltage at the batteries is 12.2V no alternator output.. I'm thinking since I live in warm Southern California and never turn on the grid heaters there and this is the first time I turned on the air compressor with the grid heaters maybe when I shifted the trans to drive there was enough load load increase to blow the 5 amp fuse that I installed in the field lead, blue wire, between the alternator and the PCM. Sure enough that's what it was. I didn't listen to my own advice when I was testing the amp output to the PCM an suggested a 7.5 amp fuse be used and installed a 5 amp fuse. During testing I had a reading of 4.53 amps with the engine running and all lights on and heater fan at full speed and thought there should be a little higher amp fuse to withstand a load surge. Well, problem solved with a 7.5 amp fuse installed. https://mopar1973man.com/cummins/articles.html/24-valve-2nd-generation_50/51_engine/electrical/alternator-and-pcm-protection-r617/ https://mopar1973man.com/cummins/articles.html/24-valve-2nd-generation_50/51_engine/electrical/grid-heater-bypass-r618/

-

Boost Level with Quad

Get an adjustable boost controller so you can dial in the max boost you want.

-

Anyone seen any new 2022 Dodge Cummins trucks yet ?

- Oil Pressure and Crankcase Vent

No. It could have high crank case pressure with possible oil leaks from seals.- I have 4.10's

You can use this link to find the size tires/gear ratio you want. https://tiresize.com/gear-ratio-calculator/- Spongy brakes and Brake and ABS lights on

I was thinking the same thing. The ABS module performs a self test on start up.- So,.......I bought it. New to me 5'er

Congratulations on the score. It is a monster compared to my little 24.5' 5er. You can do one of two things that will raise the trailer height I can think of. The first thing I thought of was to flip your axles. A friend of mine did this and raised it so high he has to put an extra step to get in. The other is to weld spacer blocks to the frame then weld the spring shackles to the blocks. Don't just add blocks between the axle and spring; lateral loads can twist the longer U-bolts and pop the spacer blocks out.- Cutting Out Under Hard Acceleration/Above 68 MPH+ 2500 4x4 47re

I wouldn't. Some people here like them and others had to replace there tanks after installing a sump. @015point9 can tell you about his bad experience with one.- Cutting Out Under Hard Acceleration/Above 68 MPH+ 2500 4x4 47re

The wiring that runs along the steering column in the cab is shielded from it's rotational movement. There have been reports of wire brakeage at the point where they flex due to the column tilt feature. OP stated that the problem all so occurs " under hard acceleration from low speeds to highway speed and also cruising along above about 68 MPH" where steering is at a minimum.- Cutting Out Under Hard Acceleration/Above 68 MPH+ 2500 4x4 47re

Have you tried the push-n-pull test. You do this with the truck running; you push and pull on every part of the engine wire harness and all connectors. - Oil Pressure and Crankcase Vent