Everything posted by Great work!

-

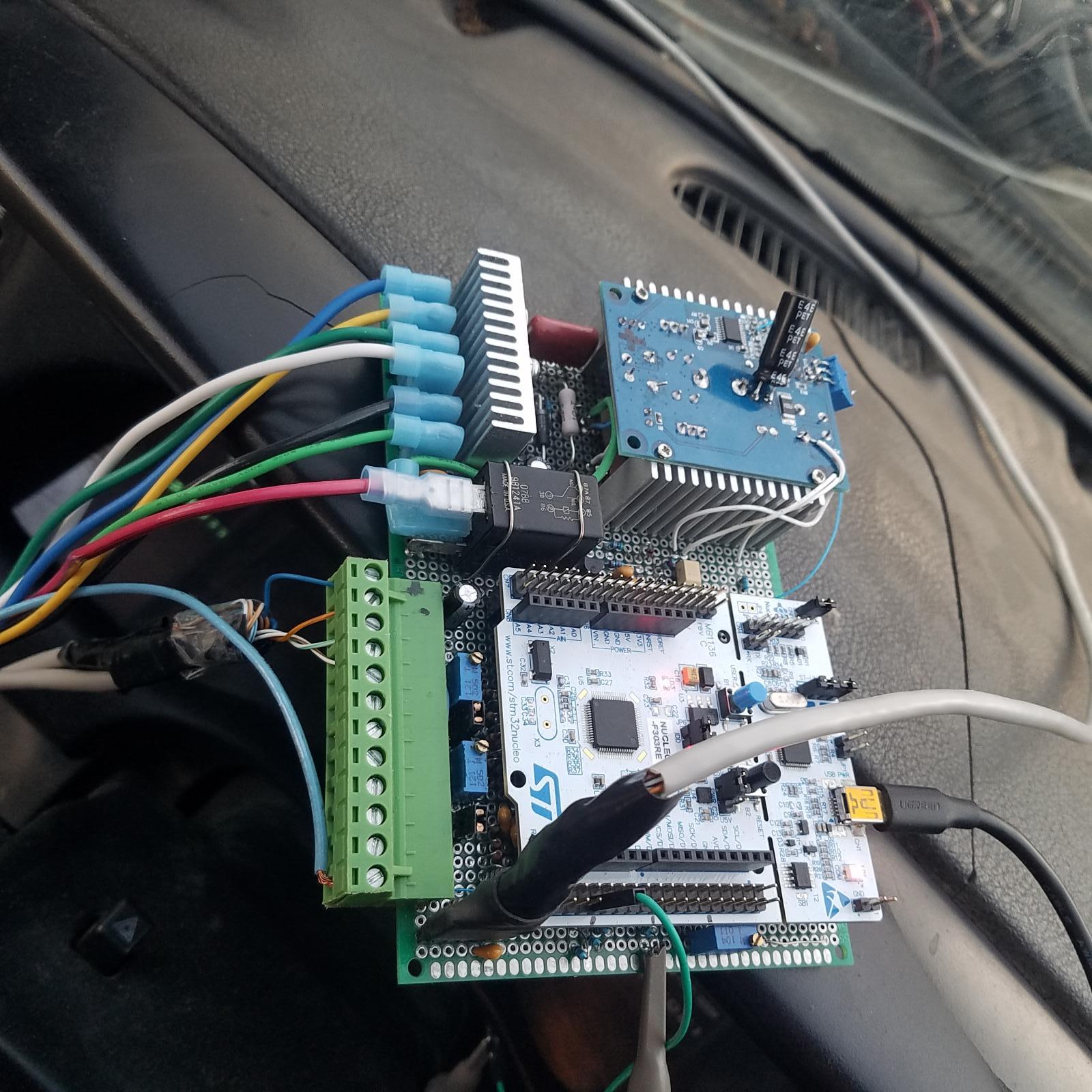

DIY vp 44 and ECM. It runs, very happy

Originally this was going to replace the controller that sits on top of the pump. But when me ecm failed and I found out they aren't made anymore I just combined them. It can do 45 deg of injection and 9 to 30 deg of timing. 40 deg of timing is possible with a shorter timing piston. I ran a simulation at 4000 rpm and that is asking alot of the inj sol. It only moves so fast kinda like valve float, and that's what will probably happen with my stock tired motor.

-

DIY vp 44 and ECM. It runs, very happy

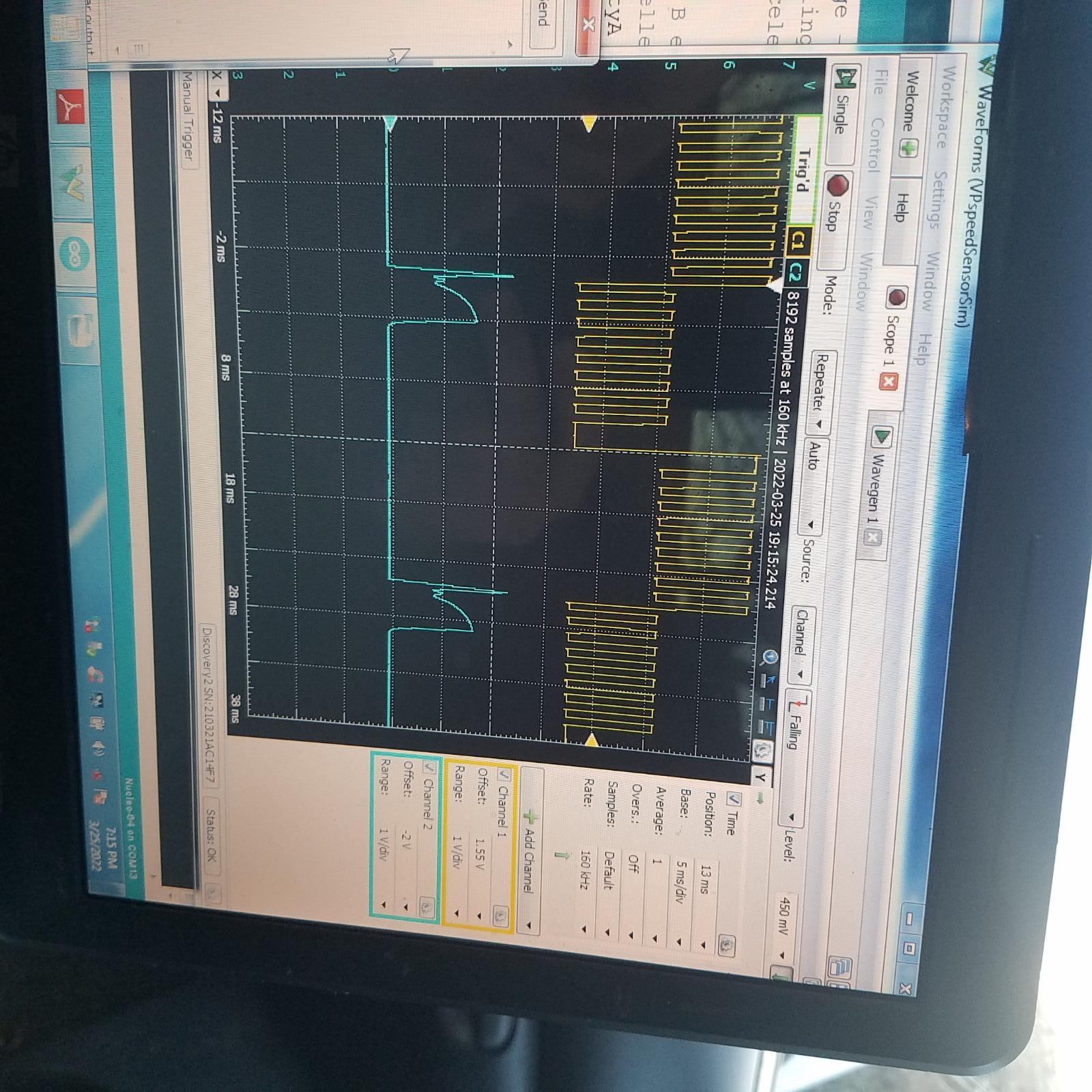

Update: hooked up APPS today and set some limits on that, made a better idle governor and improved the transition from idle to off the governor. Added a crude rev limiter and over speed shutdown today. Even with the WT-mod the sensors are very noisy. I tried smoothing the tps with software and hardware but to seriously reduce noise the throttle response gets a little slow. I'm going to try sampling the tps when both solenoids are off instead of randomly, the high current spikes seem to cause most of the noise. @Linuxpointed me to a method to chart temperature sensors using 3 voltage vs temp reference points and the Steinhart - Hart equation. I also saw @Chris O.and Lorenzo's github about CCD and I played around with it a couple years ago on a spare inst. Cluster. Definitely going to add some sanity checks as @Mopar1973Mansuggest. I actually had it idling at 575 RPM now I know why they idle at 800.

-

Engine only revs 0 to 1400 RPM and “no bus” issue

Are you getting a wait to start light blink when you turn the key on. That means the ECM booted up and is alive.

-

DIY vp 44 and ECM. It runs, very happy

Main difference is there is no CAN bus. The tune / tables will be self contained and work off of TPS and MAP. So far I have 2 timing tables full load and no load indexed by RPM. A value between full and no load is chosen by load or simply fuel quantity in a diesel engine no fuel to map table yet. Fuel is just what ever the TPS is. Other differences are the cam and crank sensors feed directly into it and are decoded into engine position without the ECM. A tach signal is output to the PCM to turn on the rest of the truck. There is still much to do. I need to translate the other sensors from voltage to temp and pressure and the convert that to CCD protocol then add a bus driver to the hardware so that the gauges work. Grid heaters are manual for now and lift pump power is tapped into the auto shutdown relay just like a gas truck for now.

-

DIY vp 44 and ECM. It runs, very happy

The hookup is pretty ugly right now. Since I had the ECM open anyway I soldered wires on the circuit board in there on the connector instead of hacking up the wire harness. I cut the wires from the psig to the solenoids and put quick connectors on. I also had to tap into the speed / angle sensor of the vp under it's cover. Tried to make a 5 min video on YouTube but I forgot to record it in low res so it was going to take hours to upload so I skipped it for now.

-

DIY vp 44 and ECM. It runs, very happy

My truck finally runs again. My vp failed and was rigged with an external transistor years ago. Then the dreaded delayed wait to start issues for a long time then the ECM finally died a few months ago. It only ran in the hot wire test mode, idle only. So I made a microcontroller project to do it all. 3 hardware versions and 7 software versions and a lot of simulation and testing later I hooked it up for real today, turned the key and it started and ran, pretty good actually. I'm very happy😀. Still a long way to go though. The mysterious VP44 has been cracked.😎

-

Midna's build

8 to 9. Degrees is as low as the vp goes internally the cam ring won't retard any more. Mine wont go below 8.8 degrees. The vp does a little trick electrically at cranking RPM to reduce it 6 degrees more by starting injection on the 21 tooth edge instead of the 19 edge past the index tooth. Each tooth of the vp tone wheel is 3 deg at crank. A single byte in a mostly static CAN message from the ECM changes from 0 to 2 to command it.

-

1998.5 47re auto hard OD shift

There is a strictly hydraulic valve in there that prevents downshifts when ever the converter is locked. The PCM has to electrically unlock the converter clutch solenoid before a downshift can happen. many shift kits have a bigger port in the separator plate for firmer OD and TC lock. There's also an accumulator/valve for the OD. It's very common for the spring on that accumulator to break. Most people don't notice when it breaks.

-

01-02 motor swap

You might be able to simply screw the 02 sensor into the 01 engine. The engine should not have a sensor by the starter, the hole should be blocked off or never had a hole cast. Keep all the 02 stuff and swap it over to the 01 that's the easier way.

-

Anyone here run Gloshift gauges?

I have a glow shift all in one. It's a bit flimsy but has worked for years. Biggest complaint is not very dimmable at night, but thats the same problem with many other brands.

-

2014 Ram with slipping clutch and blown rear main seal

I hate messing with all the crazy wire clips and plastic locks on fuel lines and hoses. You can't reach em or see em and need some special tools.

-

HX35/40W Turbo bearing failure

Have you ever thought about a newer gen variable turbo on it? It would probably be a big hassle controlling it. I just wonder if it would bolt on.

-

Dreaded P0216 code, help/advice

Mine was a gearotor style looks like an old Carter type. The motor runs dry and only has bronze bushings on the shaft instead or bearings.

-

Dreaded P0216 code, help/advice

I still have my stock lift pump torn apart in a box. It looks like a well built OEM style pump but nothing fancy. The pump, motor and brushes look pretty beefy. I think the mounting location was a big mistake. The heat and vibration from the engine plus drawing fuel up hill from the tank was what killed them. The ECM powering them directly was another mistake. Not having a fuel pressure warning system was the biggest blunder I bet all the warranty claims wiped out any savings from skipping a $5 pressure switch and snubber.

-

Fuel in Oil, not sure what to do!

You can add UV dye in the fuel filter and then use a UV light to look for leaks.

-

Dreaded P0216 code, help/advice

So to muddy the water further, suppose that a small leak on the pump intake causes foaming that's not the same as cavitation. In that case a return line prevents a big air pocket from forming down stream.

-

Manual to Auto trans conversion

Most parts shared with gas trucks are easy to get at a junk yard or online. The diesel stuff like flywheel and heat exchanger are much harder to get and cost more.

-

24v partial pedal issue from hell!

That part at the bottom is the timing control solenoid.

-

24v partial pedal issue from hell!

It's because they don't want to replace the computer and solenoids on the pump. They lose money on that part it costs almost half the rebuild and has to be programmed. The wires on the back of the pump get old and crumble too. The timing piston is probably just 'cleaned up' and reused. If you destroy the electronics to guarantee it gets replaced they void your core even though they say it always gets replaced.

-

Squirrels Got Me Good

Every Cummins in a Dodge I pulled the cab. Three trucks now. I use 2 tractors with buckets and 4 inch wide straps, bolted to cab mounts. Lift cab pull truck forward set cab on planks across bed. Always remove radiator first. Me and a helper can do it in about 1.5 hours. Unbolt master cylinder from booster leave lines connected . Parking brake cable and AC lines are the biggest hassle. Good luck on the wiring. That would be a very expensive job at the dealer they would replace it all.

-

Squirrels Got Me Good

That's going to be a real mess to repair. You can try to find new pins and then try to crimp them without a special tool and still the wires will be shorter. You may have to resort to soldering the wires together and using heat shrink tubes. I have the same rodent problems at my house. I have some new kittens that are getting bigger now so that should help. The rats ate every thing in my jet ski, even metal parts.

-

Injector size as it relates to Quadzilla tuning

I would like to see the vp44 cam donut from an HO and SO side by side to see if one has a different ramp profile.

-

Replacing the Cooling System

Check valve is in the fittings for the steel lines you access it from the bottom with lots of cussing. OEM hoses lasted 20 years so replace with top quality or silicone hose.

-

Another radiator leak thread, this the season

In a pinch, I have used the green bondo with fibers in it, some call it tiger hair. It sets in minutes and can be packed into the cores even.

-

Oil Analysis Readings

Oil analysis tells you about the oil more than engine wear in my opinion. Look for high silicon or copper that's usually from wear. Any fuel residue over 4 % indicates needs looked into especially on electronic injectors. I send in lots of Rotella for tests it's good stuff. The Cat red coolant is good stuff too.