- Replies 91

- Views 16.1k

- Created

- Last Reply

Top Posters In This Topic

-

Dieselfuture 39 posts

Dieselfuture 39 posts -

Mopar1973Man 13 posts

Mopar1973Man 13 posts -

mossyoak71 13 posts

mossyoak71 13 posts -

wil440 5 posts

wil440 5 posts

Most Popular Posts

-

Will do, it was my plan. Now we just need some hope they fit. And also if they fit on my head I'm hoping that's how rest of heads were machined. All else fails we already have a great place to b

-

I'll try to dig around here in the industrial field, but I remember at our Loc-Tite seminar the one point the guy pushed about what makes Loc-Tite work is absence of air, presence of metal. Loc-Tite w

-

Took a look at the Lions Head bottle and it says it's not bothered by gasoline, oil, and specifically mentions diesel oil being OK. Just thinking, what about one of the many Perma Tex products? They'r

These ford seals may or may not work with sertain valve springs, be sure to measure all Id/od before committing.

So I'm in process of figuring out why some of my seals are tore/smashed. Finding out that new style seals 03 and up may work on our 2nd gen. They are held in place by spring and can't come up from too much boost etc. I've spoken with https://ussealparts.com and they have both styles at great prices, although top hat style is listed for 03 and newer. The difference I believe is in ID where it slides over guide, sounds like top hat is slightly bigger but that should not affect the sealing capabilities as valve still same diameter. I ordered both styles and let ya all know. Now this place advertising them as they do fit. https://puredieselpower.com/dodge-products/dodge-6b-cummins-intake-valve-seal-exhaust-valve-seal-set-b45962-b45963.html#/product/21380

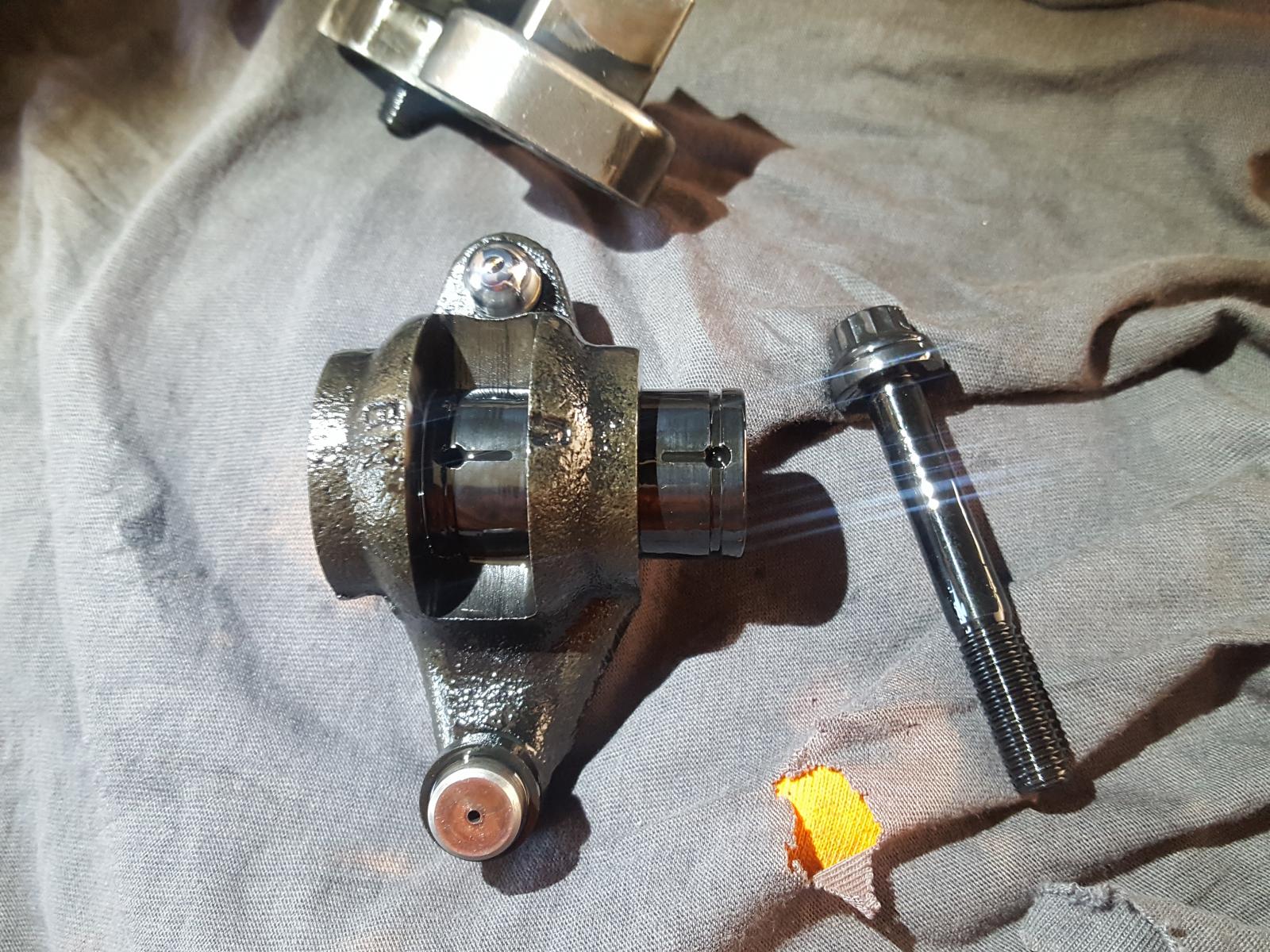

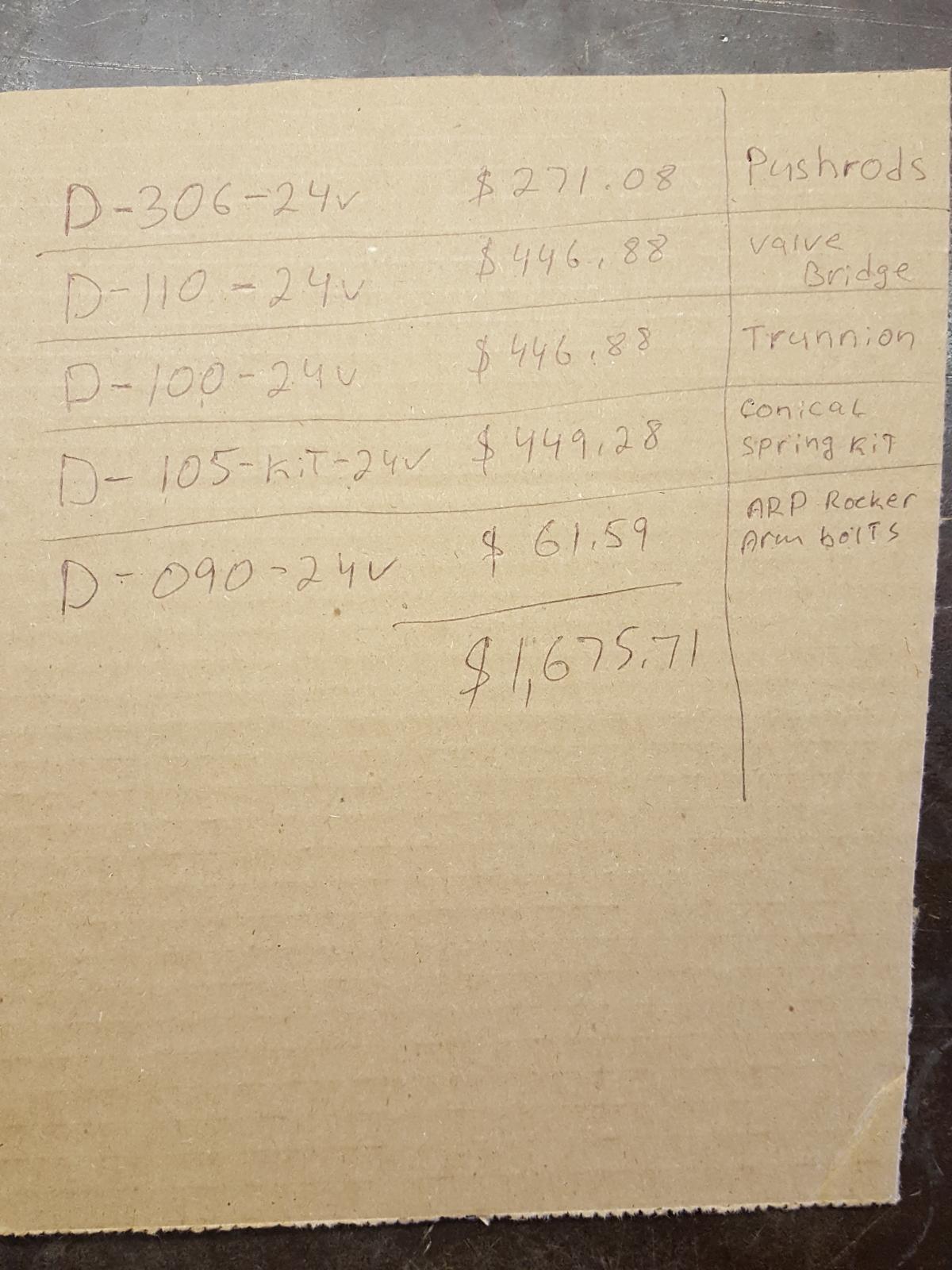

Another thing I might be doing is upgrading to better push rods, springs, trunion bearings and roker arm bridges from Manton. That may explain my ovaled guides and smashed seals, or so I hope.

Let me know your thoughts

Edited by Dieselfuture

Added info