- Replies 16

- Views 2.2k

- Created

- Last Reply

Top Posters In This Topic

-

Unreal Summit 6 posts

-

wil440 3 posts

-

Bullet 2 posts

-

dripley 1 post

Most Popular Posts

-

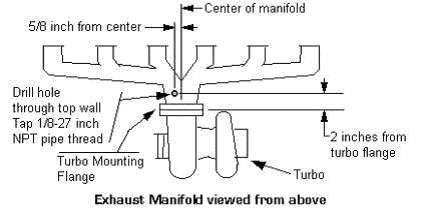

Here's where mine is drilled... turbo was off so I can't be any help with the filings

-

Measured while off and cold. Drilled while cold but running...no grease. Started with real small pilot bit so that each following bit had constant air flow passing around it. Smaller increment bit

-

I drilled my hole most of the way through then started engine and completed hole. Shut engine off and cut threads with greased tap. Very easy process.

So I am finally going to drill and tap for a egt probe this week. My question is should I start the truck or just let er rip and use a pen magent after I get the hole drilled? Wouldn't running the truck suck the shavings instead of blowing them out the hole? Just wondering what's my best plan of action as to not cost myself more later? I don't want to take the turbo off because I am sure the bolts will be wonderful to take off.