- Replies 23

- Views 6.2k

- Created

- Last Reply

Top Posters In This Topic

-

David454 7 posts

-

Mopar1973Man 6 posts

-

Dieselfuture 3 posts

-

Tractorman 3 posts

Most Popular Posts

-

The 2 wires going to vp module are stainless steel, the ac noise is measured at alternator with good quality vac meter at alternator stud not batteries or any pumps. Sounds like dirty connection are a

-

Metal Fuel line likes to crack or rot right at the top of tank.

-

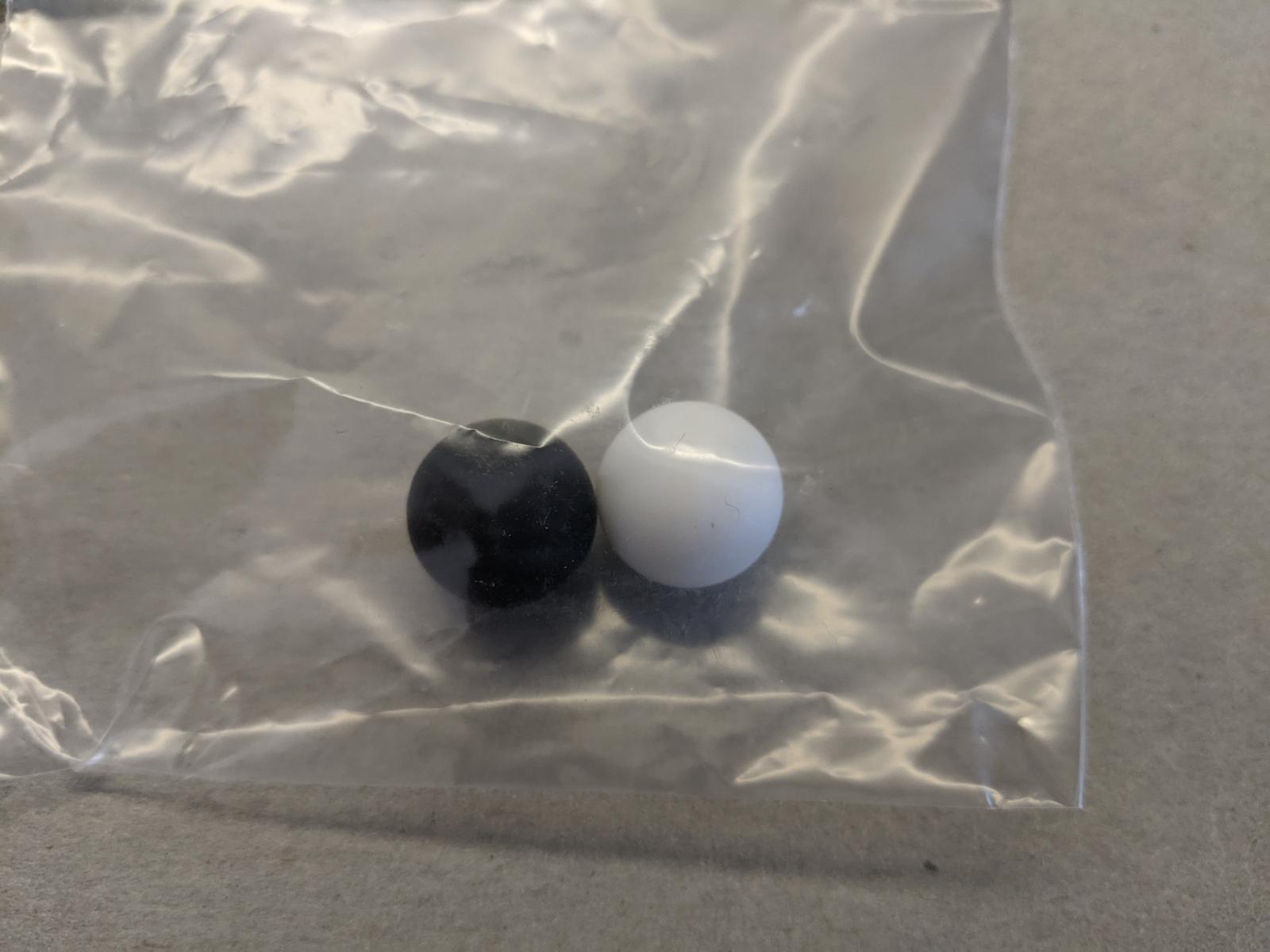

Ok. You need a snubber installed before the pump and stack on the sensor. Similar to this...

I've got an 01 6 speed HO with 160k on it I bought not too long ago. Previous owner had installed a FASS and Edge Juice on it. I went to clean up some line routing/wiring and noticed what I now know to be the timing solenoid wires were completely bare at the top outside the sheath. I poked around that area a bit, looked over some fuel pump wiring/hoses and then quit for the night after I saw how much work I needed to do.

Next day I fired it up (still hadn't done anything but literally poke the wire bundle around to look at it) idling rough, p1690 pops up (no other codes) I shut it down and decided to swap the crank sensor. No change with the new crank sensor, so I went through the rest of the diagnostics I had found on here with no luck. All wiring to the ECM and Cam sensor is sound. All wiring from the vp is sound, grounds are good (less than 1 ohm on my volt meter). I don't know how to check the AC noise from the lift pump but I have a FASS so I would hope it's fine.

I decided to look more at the bare wires for the timing solenoid I had poked, found that there was no evidence of ever having insulation on them (I found other pics of similar situations that seemed like they came factory like that). I wrapped them in electrical tape the best I could, started it up and wala, no codes and idling well. 5 min into the drive I heard the timing change and the CEL popped back up, no power of course, with the same one code p1690. Back to the way it was.

I figured my electric tape job might have been the fix but just not done well enough, so I redid that with some liquid tape added too, and this time only got a minute or two into the drive before the issue came back. Also during this process I tried unhooking the alternator and didn't notice any difference. Tried letting it get back completely cooled off without touching the tape and still having issues so I'm not convinced it is engine temp related.

Only other pertinent information I can think of is that it got below zero here last week and I'm sure the fuel gelled, but I didn't drive it until the temps were over 40 degrees. It always showed good fuel pressure (13+) and made an hour round trip the day before the issue started without a problem. Could the fuel gelling cause pump issues inside it or some residual wax floating around cause issues even after over on hour of trouble free run time since temps were below freezing?

Do yal have any other ideas on what this could be? Truck is undrivable at this point.