- Replies 29

- Views 2.8k

- Created

- Last Reply

Top Posters In This Topic

-

Tractorman 9 posts

-

wil440 7 posts

-

Mopar1973Man 3 posts

-

Silverwolf2691 3 posts

Most Popular Posts

-

Some of us kept reading but let you two discuss out the finer points without too many jumping in the middle of the mess. Thats one of the nice things you two can discuss out your different views and c

-

100% agree John and this thread has been well worth the hijack (probably more me than you though that's done the hijacking) As you said my friend each one of us waking up in the morning to

-

@Tractormanand you were doing a fine job discussing this issue. If I had injected may into this conversation that's about what it would be worth. Sometimes it's better to sit back, eat popcorn, an

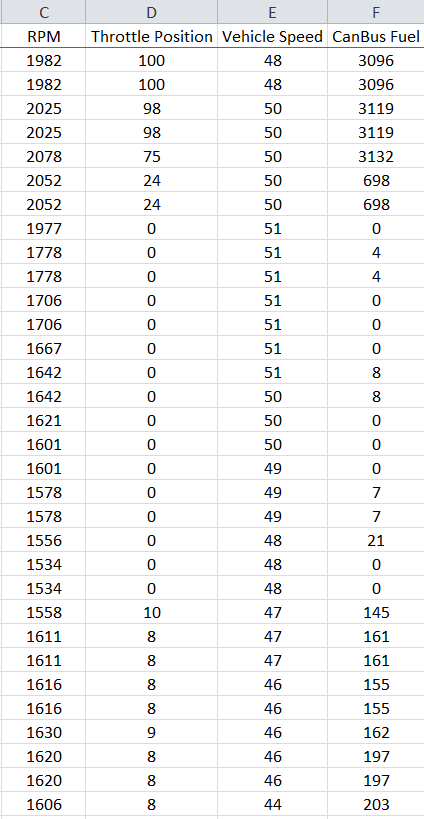

I can't seem to find a source that has a conclusive answer to the question, "Does the VP44 completely shut off fueling when truck is coasting in gear on a downgrade?" It would seem to me that the VP44's high pressure solenoid valve would stop receiving signals under this condition if the APPS signal was at 0% (foot off throttle). Does anyone know if this is true with certainty?

An example would be: truck with a manual transmission coasting along on a down grade at 1700 rpm with foot off of throttle.

- John