- Replies 19

- Views 2.4k

- Created

- Last Reply

Top Posters In This Topic

-

pepsi71ocean 5 posts

pepsi71ocean 5 posts -

IBMobile 5 posts

IBMobile 5 posts -

Mopar1973Man 3 posts

Mopar1973Man 3 posts -

2000Ram2500 3 posts

2000Ram2500 3 posts

Most Popular Posts

-

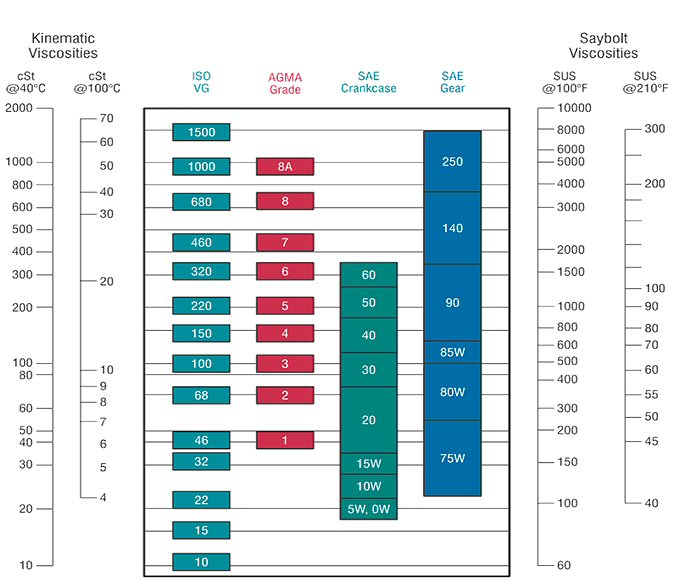

You might want to look back at my post I did look up the viscosity of ATF+4 and its thinner than you think. I was editing my post to add this information. Yes I do understand the viscosity differences

-

What I would like to do is use the momentary switch, that is on my shifter, to engage the EB when the Pac Brake controller won't let it. I think I can wire it so the solenoid will put air to the pist

-

Well everyone I checked the fluids cold, and later hot. I took it for a spin and it shifted just fine with the engine brake on. I also discovered that the pacbrake locks the torque conver

Hey everyone,

I have been playing with my 47re with my pacbrake. I'm starting to wonder what is a good healthy line pressure when engine braking.

Right now I'm seeing 80-85psi at idle in drive, and driving down the road were about 110 with my foot out of the throttle. In the throttle I'm seeing about 125psi.

When I'm engine braking I see about 115psi going from 2,000 to 1,250rpm.

When I'm downshifting and in 3rd, I can move it to M2 and it will downshift at 32.5mph 1,250rpm.

I have a lower stall torque converter and it seems to brake hard even on second. I was looking to see having the TC lock up when downshifting in second, but dynamic supposedly built it to do that, but so far the pacbrake hasn't done it.

That's another issue I need to deal with.

Any advice or input here, @Doubletrouble