- Replies 106

- Views 15.1k

- Created

- Last Reply

Top Posters In This Topic

-

Callsign 21 posts

-

Marcus2000monster 17 posts

-

dripley 16 posts

-

Mopar1973Man 15 posts

Most Popular Posts

-

Whats happening then is the AD is running at a full 18 psi (your setting) when the key is ON. This means the VP is receiving fuel incoming pressure while the engine is cranking, which then increases

-

I should say that I have NOT heard it in a good while. My heating aint what it used to be. You reckon 434k in the 2nd gen might have something to do with it?

-

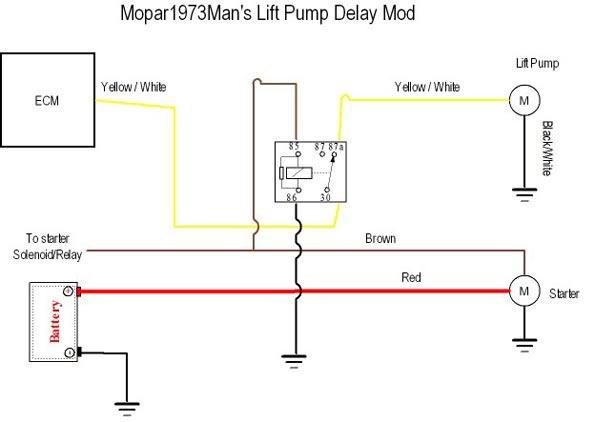

Fuel pump relay is ONLY for the vp44 in these trucks. It looks like the ecm 5v ref is shorted based on the P1475.

First real post here, been lurking in the back ground but now I have a issue you all might be able to help me with. Ok got a 02 gen 2 nv5600, air dog pump. Start it in the morning to warm up (plugged in over night) and blocked wheels cause my driveway is on a incline and my ebreak is not the strongest. Come out to leave and have to put it in gear and shut off truck then remove blocks. Go to start back up and will not start just cranks but does not fire. Now I've been able to get it to start 2 different ways when this happens, either with ether or with my smarty using it to clear the 4 codes it shows. Those codes are as follows.

P0232

P0230

P1475

P1693

Now ive been told i need a new vp, a new pcu or ecu, could be ground issue, could be fuel pump relay issue (already replaced).

Who has had this problem? What was your solution?

THANKS IN ADVANCE!