- Replies 65

- Views 11.6k

- Created

- Last Reply

Top Posters In This Topic

-

Manimalmother 24 posts

-

dieselautopower 11 posts

-

Mopar1973Man 6 posts

-

Dieselfuture 5 posts

Most Popular Posts

-

Gotcha. I'll put that on my list. By the way, I caught my pregnant wife on my security camera. She stole my hoodie!

-

Well I got the housings back this evening. The exhaust side is ceramic coated silver and the compressor housing is powder coated "titanium pearlcoat". He then masked and did "holset" in gold. We'll

-

Correct, It will help top end power. Low end spool up will be slightly inhibited as you will lose some of the pulsing of the twin volute. Reducing back pressure is important. 1.2psi bac

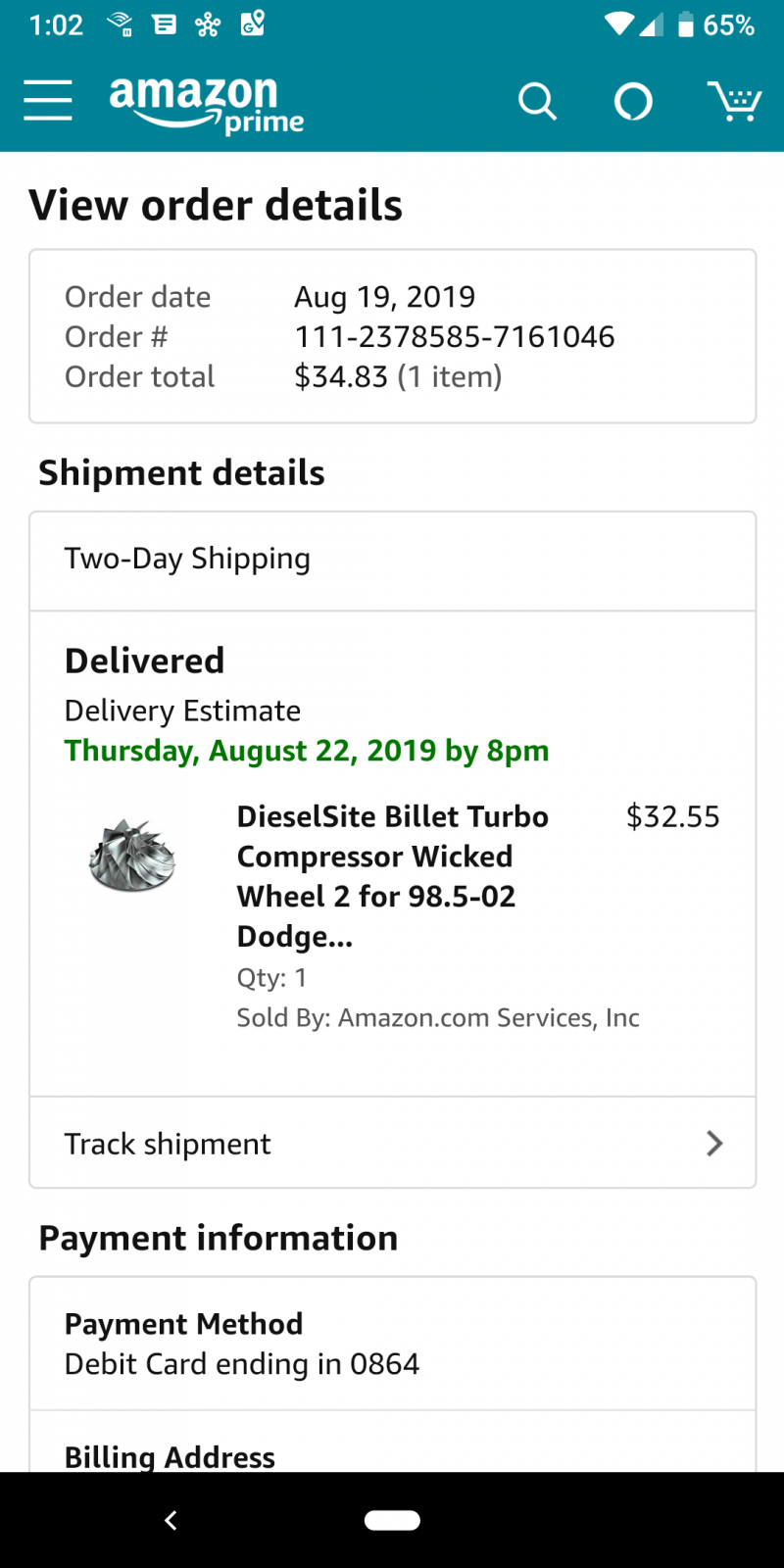

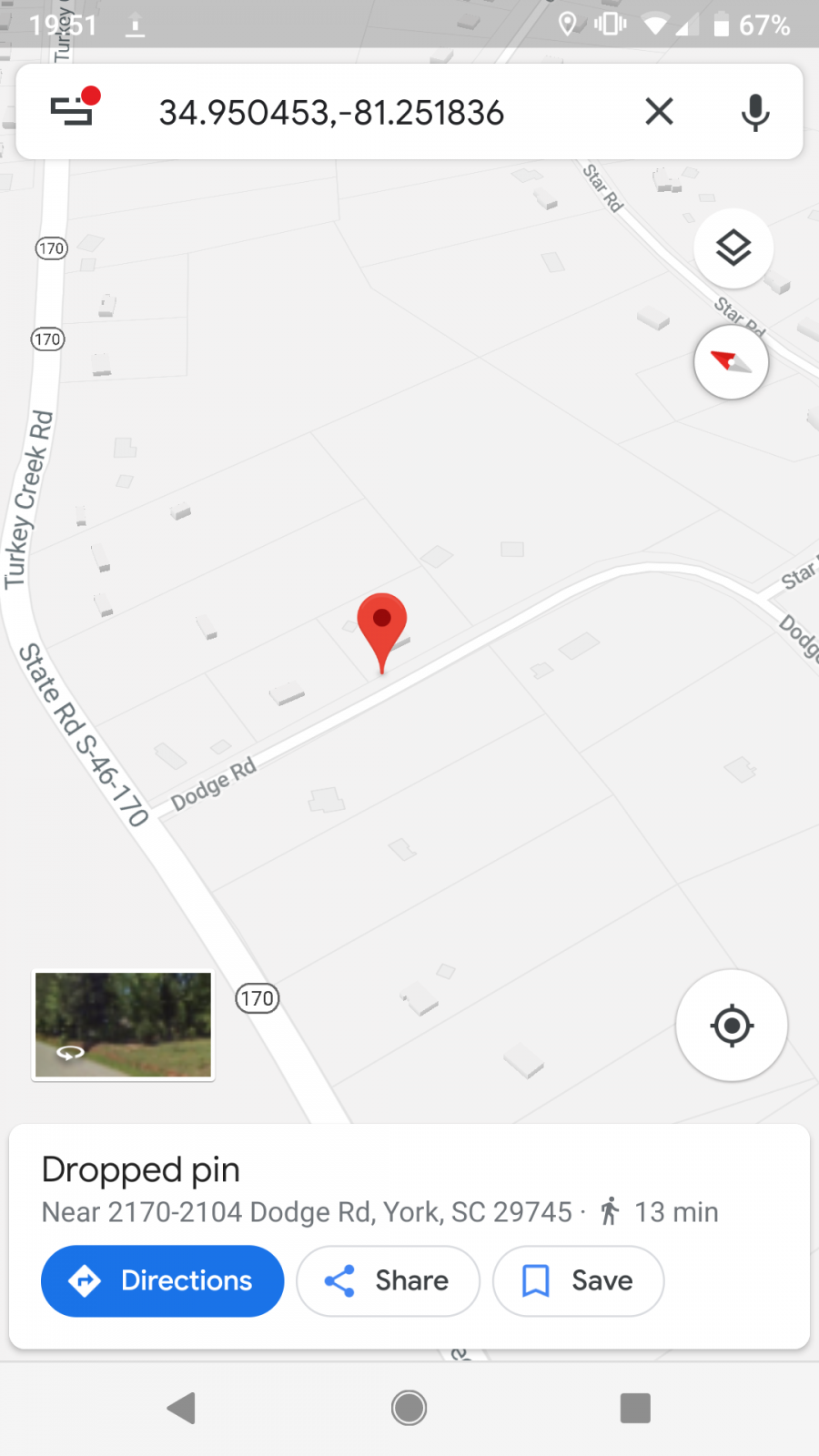

So last week I installed a set of 7x10 injectors. I am thoroughly impressed with them but they make me nervous with my stock HY35. I'm traveling for work right now and happened on a good deal on an HX35 off another 01. I scooped it up because of the price. No shaft play and looks pretty good. From what I've read this should be a direct swap for the HY. Is there anything else I may need? I'm planning on hauling my fifth wheel back home Friday and may try to install in the hotel parking deck. I'm sure they will love that! The HX should have lower EGT's than the HY correct?

Thanks!