- Replies 69

- Views 10k

- Created

- Last Reply

Top Posters In This Topic

-

Manimalmother 26 posts

-

dripley 13 posts

-

Mopar1973Man 12 posts

-

Dieselfuture 10 posts

Most Popular Posts

-

As stated it is not required.. thou many do it and get some decent movement out of them. When I did mine it was all per the install instructions. I then re-torqued them and got movement on all of them

-

She's alive. I was only available to work on it at night after work and it took me a couple of days. After lots of fuel line bleeding I finally got her started yesterday after

-

@dripley, I think he just hung the head from the wiper arm while he cleaned up the block. They don't make wiper arms like they used to. - John

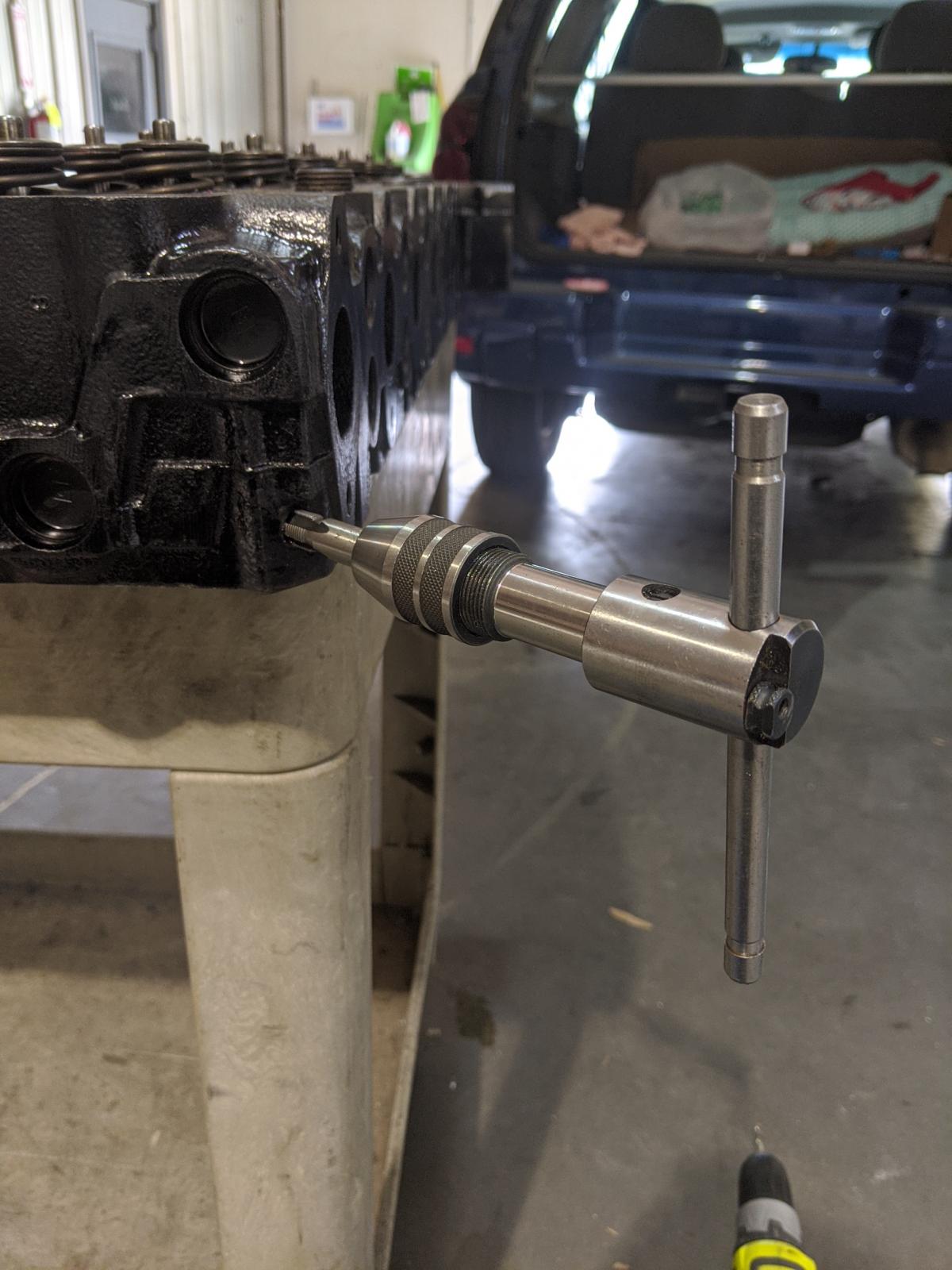

So Im in the middle of swapping back to the HY while I rebuild the HX and the sun caught the back of the block just right and I see this. I'm guessing it's the head gasket. Agree?