- Replies 69

- Views 16.2k

- Created

- Last Reply

Top Posters In This Topic

-

Doubletrouble 25 posts

-

Mopar1973Man 14 posts

-

wil440 10 posts

-

dripley 9 posts

Most Popular Posts

-

That switch is expensive and I'm sure if I had a manual and it failed it would be in the bin, I remember 40 odd years ago doing my apprenticeship.... HGV mechanic, the workshop foreman was servicing a

-

I have to add one from the dumb *** switch part. I had heard stories that you could back up against a wall and let clutch out and the Cummins would just sit and spin the tires. So once at work a year

-

Well, it's official. I got the call yesterday, I am laid off for at least 2 weeks. Time to get some things done at home. Clutch parts will arrive today and I also ordered a new base with valves and su

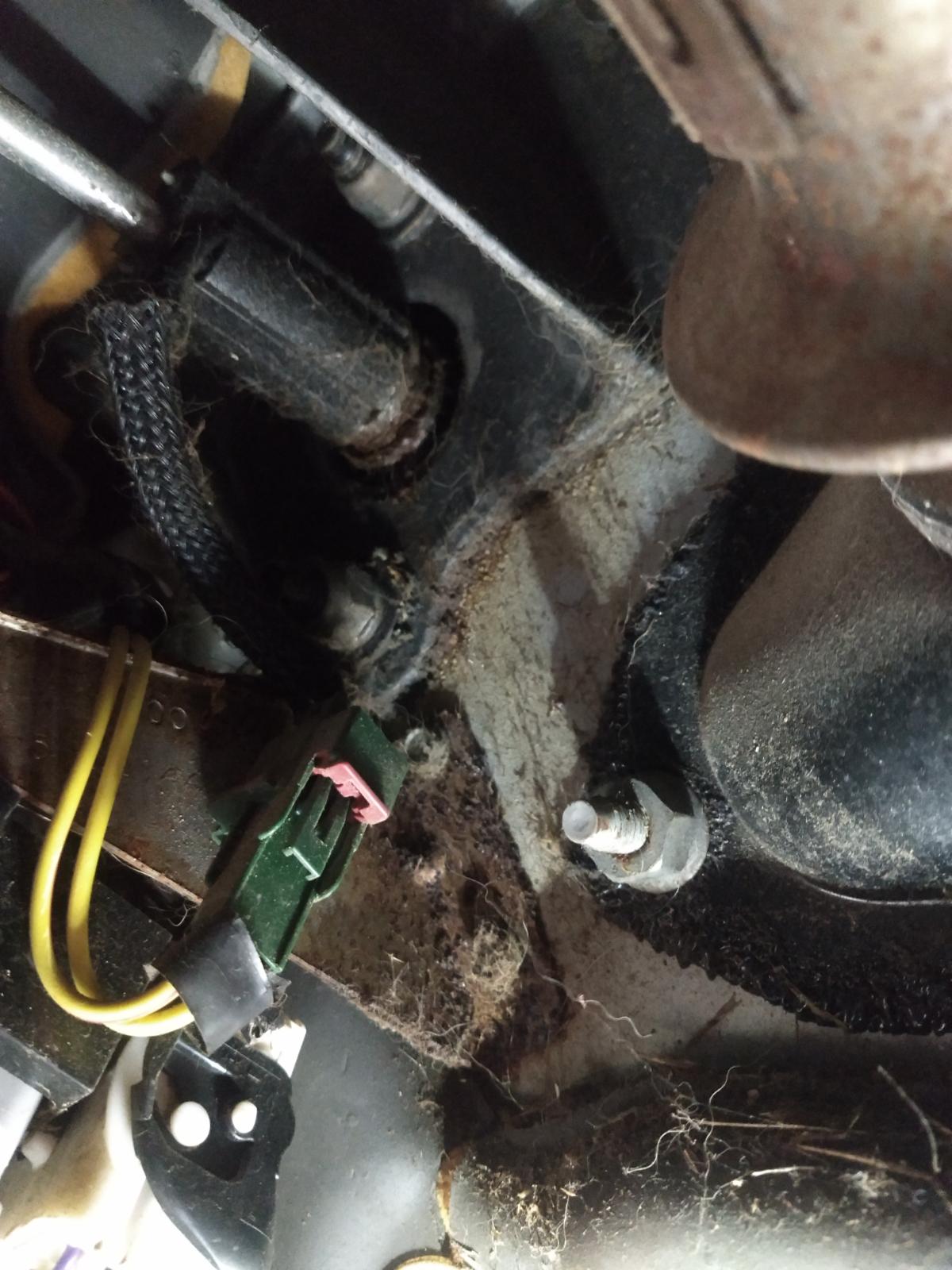

Lately I have noticed my 5 speed is getting harder to get into gear. I can feel the shifter moving between the gates like normal but then try to pull it into gear (mainly 2nd or reverse when stopped) it doesn't seem to want to go unless I press the clutch pedal firmly against the floorboard. It wasn't like that before, she used to slide into gear just fine.

With a hydraulic clutch I'm assuming there is no adjustment? Is there a way I can check anything? Any other ideas?

Thanks!