Everything posted by Mopar1973Man

-

Working on the trucks

Now I got to revisit the alternator on the Beast. I gor @Wet Vette to help me clean the truck. Then ran to town for chicken for dinner. We packed up some more stuff like a blanket. Made it to Smokey Boulder Road but the alternator quit charging. Double checked the field, circuit breaker, and protection fuse. I turned around and had dinner in the yard. Now the next thing is verify the field leads and voltage. If I got to I could bench test this alternator. Post more tomorrow...

-

Working on the trucks

Just working on The Beast. Got the steering box adjusted good. Fixing my fuse for the alternator. New seat covers and even washed The Beast off. Had to have a few tools so Thor got in on the photo.

-

2017 Ram 1500 EcoDiesel

I still think it was injectors being it won't start or run. It was sent back to the dealer and traded back in.

-

New 2022 3500 Dodge Tradesman 6.7 HO Aisin ordered and coming in the fall ???

That's about the only solution. Add it to the price of the truck.

-

Starter quit!

More to add on this... I found the ultimate cause of all this. (Be gentle ) So my exhaust brake switch is on the stick. The previous owner added a aluminum angle metal to mount the switch. Sad part is the terminals on the wire are not insulated. So when the switch loosen up a bit it will swing over and touch the nut. Now it blows the fuse under the dash. It happened a few times and I thought I wonder if the previous owner used the right fuse? I used one bigger 10A fuse. Well the circuit that the exhaust is wired into is only a 7.5A supply so it blew that fuse and then prevent starting. After I replaced the fuse in the TIPM and both systems started working. So I need to fix the exhaust brake switch, install a 5A fuse again for that circuit and then the 7.5A in the TIPM. Then everything will be well in the world again.

-

Water and Heat

Here we go again. I finally starting to get water on the yard and @Wet Vettecalls me to the bedroom. We are looking at the window and see the filter trap wiggling. I head out side and look the filter is plugging up with debris from up top. No biggy. I open the purge valve and it cleans up fast. Still watching close and seeing air being sucked in. Dang! I waited till after dinner and hauled up the mountain to my dam to just check and the water level was barely reaching the pipe. I pull the boards and clear the dam quickly. Pick up stones and debris and re-lay in the boards and seal them with moss. Nearly water tight now. Then head up the road some more to the upper diversion. Get off the ATV and the weeds are shoulder high on me. Tough to hunt for the trail buried in 5 foot of weed. knowing where the creek was I kept pushing. Finally find the creek and hiked up a bit farther to the diversion. My pipe has a spike in the middle of it and just my luck the pipe had a stone just about perfect size to plug it. Cleaned that up and gain some good flow. Packed up and hike back to the ATV. Stopped by the neighbor house to let them know water changes. I found a place near me that sells the sediment filters so I'm going to try calling the company Monday. I got back home and the sprinklers have gained about another 20 feet of radius. Now we are getting the water on the lawn and yard. As for my creek the water is low and it way early for low flows like this typically its mid to late August before low water happens. The river is about 500 CFM lower than normal too.

-

Summer time heat

Rust will be for sure in the block. Like the last time I had the head off the coolant jacket is just surface rust and meaningless. Nothing to do just leave it alone. Now if your flushing and seeing large flakes of rust you might have to discuss this with a radiator shop on different products or possibly have a shop capable of dealing with heavy rust. Scale that builds in the radiator is a sign of wasted coolant. Coolant main purpose is to correct the pH balance in the system. As the additive package is consumed now you start eating metals in the block, gaskets, etc anything that touching the corrosive coolant. This might be either direction acidic or basic. Now the oxides of metals cool at the core tubes in the radiator and deposit themselves to the metal tubes. I don't have ANY scale in my radiator even my factory radiator is perfect yet but a blown tank seal. There are chemicals that can eat at those materials but the problem is how strong of a chemical, how long to leave it soaking, etc. Again a professional radiator shop would know more. Personal I've never had any issues because I typically flush the coolant system by about 70k to 80k miles. If there is ANY color change of the coolant it already too late! A side thing I love to do. I'll get a client that needs a radiator flush and I'll start draining the coolant they always say "See it still looks good!" I just smile and stay silent. As it comes to the last gallon and coolant start to change to rusty color I now speak up and say"Nope. The rust just proves the additive package was gone". Then typically I look in the tanks of the radiator and you'll find starts of scale blooms. The owner is now speechless and like the last one said it was factory coolant and nothing ever been added. Just because its factory coolant doesn't mean the additives will last forever. Another side note. I've been doing my own testing. Now I've been doing my coolant system flushes with creek water or well water. Never used any distilled water in 431k miles. The block is still clean inside, light surface rust that is all. ZERO scale blooms in the radiator. Both waters I use is very clean and clear and drinkable. Very low mineral content. Water pump... Hmmm... I'm still running factory OEM water pump. I've never changed a water pump yet on my truck. Again I keep good coolant in the system so there is lubricant package for that too. Again wasted coolant will no longer be able to keep water pumps lubed so the shaft seal fails and now you see the weep hole bleeding coolant.

-

Runs rough when warm, mixing diesel and oil

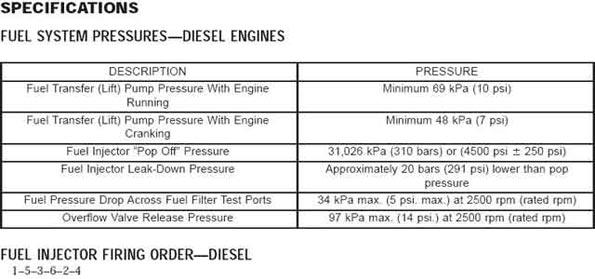

They should be all popped together to be matching in flow rate, and pressures. What good is to have one cylinder flowing more fuel and the other cylinder could be lower amount or higher volume yet? This is one reason I do not suggest Bosch stock or Bosch RV275's. Now all injector shop will start out at a +50 HP injector. Now you able to flow match and set pop pressure. Now I will not suggest adding extra pop pressure till your up in the +100 HP or higher. There is no real gain for small injectors being popped higher pressure. Give you an idea typically I see stock injectors that are newish idle with about 6-7% engine load. My DAP 150 HP injectors (7 x 0.010 @ 320 bar) when I fired up and was watching the Quadzilla it idles at about 13% engine load. This gives me an angle of longevity because once an injector set finally reaches 1% or 2% for engine load at idle they are basically done and wore out. Why the change in engine load? Ok that's easy when the injector is new like what I've got set at 320 bar the ECM calls for more throttle 13% just to make it idle because of the high pop pressure. Now as the injectors wear and the pop pressure falls now the engine load will get down to 6% to 7% like stock injectors might see. As it continues to wear out the pop pressure falls below 290 bar the engine load will drop to 0%. Now you see idle speeds rising above 800 RPM which the ECM is programmed too. ECM can't cut any more fuel because there is nothing left to cut. Being the injector is opening easy and early the idle speed will rise. When I finally gave up on my factory stock injectors at 150k miles the idle speed was 875 RPM and engine load was 0%. Now this is why I say to replace injectors between 100k to 150k miles because most injectors are well below 290 bar for sure by that time! My old +75 HP injectors I got from Vulcan Performance they falled at 75k miles and they started life at 305 bar. So it didn't take long for those to get below 290 bar and idle again was rising above 800 RPM and the engine load floating 2% to 0%...

-

Water and Heat

Video is a must watch... Still in all all this talk of Global Warming or Climate change is just a democRATS scare.

-

Water and Heat

I'm sure there isn't any animal that can out run a bullet. Dead or alive... Then there is proof of the 3 legged chicken. Next time I plan to head towards Lewiston Idaho. I'll call ahead and get one.

-

I'm Back, Finally! And I have some good questions/ topics

I'm in line to getting a new dash in my truck its starting to crack badly and tough to keep up with super glue.

-

Water and Heat

Only find those in North Carolina... @dripley most likely has a private farm out there somewhere... Most likely takes them out in the "Chicken Caddie" for rides at night. Yeah its been a real task to keeping water flowing here this year. More down time than up time. I've got to find a new sand or sediment filter for my 1 inch supply line yet. I've only band-aid the problem for now. I found one in Tractor Supply I might just order it and get it coming. Funny part I bought the filter last time in Lewiston ID at Home Depot and they no longer carry it or the filter cartridge. Most of the fruit trees have been pruned pretty hard last spring so most of the production right now is slow. The cherry trees produced cherries but with the heat and lack of water they were small and dried out quickly on the tree. I'm getting water on the black berries which are now popping up and looking good gotta keep some fruit around here.

-

Water and Heat

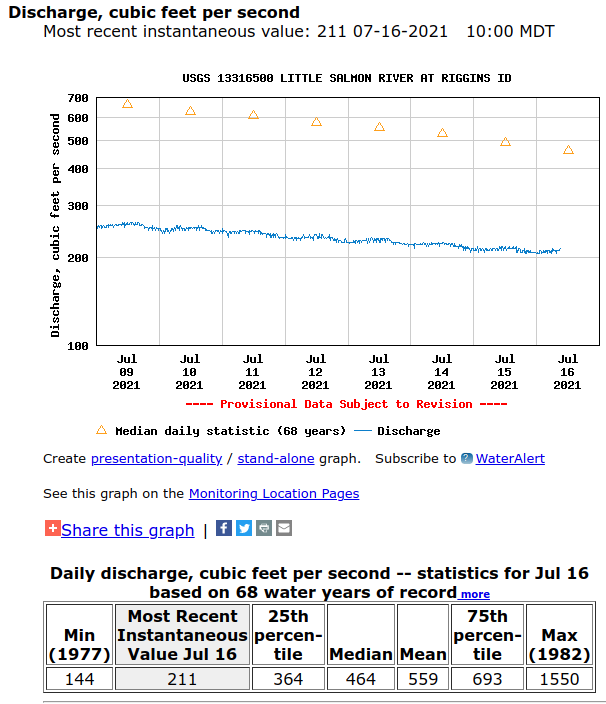

I'm starting to hear on the local radio that McCall ID is calling for water conservation. Giving guides on watering at night, using hose timers, etc. For myself its been a bad year just trying to keep water going. The loggers that log out behind us happened to damage two pots in the water line. Between the neighbor and myself we managed to get water going. Shortly after that fix I ended up having a filter problem down hill at my place. Mud and needles washed down and plugged the sediment filter. Clean the cup out and filter and now noticed the sand wore the bottom of the filter cup out. so thin it was leaking water out at 120 PSI through small cracks in the cup. I happen to have a tube of epoxy and started mixing up batches of epoxy filling the wore groove in the cup. 15 minute set up time. Managed to just get water back up. Now my yard is super dry. I lost all the cherries (fruit not the trees) being extreme heat and lack of water. Now got 2 good hoses and going to head to town soon and pick up hose mending supplies and repair my hoses and get the place watered. Weather wise its been floating right at 100 degrees here day in and day out. We maxed out at 108*F here for one day. I've seen over 118*F in Riggins, ID and Lucile ID just out working job. Rivers are all down on flow and even rafting companies are wondering how much lower the river might get. Here is the river acros the road from me. The triangles are the average flow.

-

Head Leak

So does carburetor cleaner, brake cleaner, acetone, MEK, you name it. It will dry your skin and nails out. One of the leading causes of cracked nails and super dry skin.

-

Pilothouse/RAM3500 build

I've seen a few of the older bodies back to life like this with a Cummins engine. I use to see a guy down in Weiser ID every morning for breakfast with his Cummins power oldie! He did his on the 6-BT p-pump engine but still in all its very cool to see.

-

Head Leak

Mineral Spirits will remove most of the heavy oils. Then the brake clean will remove the last of the oily residue and dry quickly and be ready for silicone and will now bond with the metals. Brake clean is about the only solvent that will dry without leaving any oil residue.

-

Runs rough when warm, mixing diesel and oil

Right out of the Dodge FSM book... So if you look stock is 310 bar (4,500 PSI). Then the lower limit is 293 bar (4,250 PSI) then the upper limit 327 bar (4,750 PSI). Little secret I did on my current injectors. I've got 150 HP DAP injectors popped to 320 bar (4641 PSI). This is something you can do with custom built injectors (but no Bosch stock or Bosch RV275's) The higher pop pressure does limit the flow a bit but the spray is much finer and economy is good to fair depending how you drive. Just remember pop pressure below 290 is most likely a total failure. I did the high pop pressure for longevity being all the past injectors only lasted mere 70k to barely 100k and started to either misfire or smoke excessive. You have to remember as pop pressure goes down the timing advances for the firing event. With my 320 bar injectors the timing is retarded but since I'm running a Quadzilla I can add those couple degrees back to the injector and get it back on time. One last thing to mention its possible to lose about 10 bar of pop pressure just in the break in period of the injector. Just something to consider...

-

Summer time heat

I'm starting a general all around thread about trucks and summer heat. I know there is lots of you out there doing searching about overheating, high EGT's and other heat issues like transmission. The biggest thing to remember anything thing that is creating heat is cause by some sort of load. Engine Cooling System Now how long has it been since you flushed out your cooling system? Don't buy into those coolants that claim 100k to 150k miles before failing. I would say about every 3 years tops should be flushed. Then about 70k to 80k miles in miles. Completely flush the block out with garden hose till there is no solid material or coolant color running out. Make sure to have the truck idling as well this will make sure the heater core is flushed out too. Flushing coolant and then refilling with fresh coolant reset the additive packages within the coolant. There is corrosion and lube package that get depleted. One of the few reasons I've not had any cooling problems or water pump issues. For those worried about thermostats NAPA I've been using for YEARS now and never had a bad thermostat. Transmissions (Manual / Auto both) I've seen a few coming to me with transmission temps getting above 200*F. Like a friend lives near me has Chevy Duramax shift issues and higher than normal temps. He did a full pan dump and change the internal filter and all this issues went a away. Make sure you changing out your transmission fluid before the summer and installing a good filter. Clean all the coolers on the front of the radiator. Manuals for us the biggest thing to help in reduction of transmission heat is just placing a heat shield between the transmission and the exhaust pipe. This will reduce the amount of radiant heat from the pipe adding heat to the transmission. You can do this for both auto's or manuals. EGT's This one could be other issues. Oversized tires, improper final ratio to the ground, excessively big injectors without enough boost to cover the fuel. Excessive weight on the truck and/or being towed. Don't be racing the truck up grade with heavy load take a minute and slow down and grab a gear lower. Climb the gear at a slower speed. Possibly with tuners improper timing for said load could also produce high EGT's. Like Edge product does not give a control for timing and typically stacking timing on top of the ECM stock timing typically this is a bit too high for towing applications. Tires and Final Ratio I know there is alot of people that like the look of oversize tire and lift kits. Just remember the higher you stand in the wind the more drag comes with that lift. Just remember the drag value is based on a square foot measurement from the ground to the top of the truck and the full width. Now as for tires remember 3.55 gearing for most of the 2nd gens. Now add larger tires to that axle and your pushing that final number down so from 3.55 it will head towards 3.00:1 like 37 inch tire will do. Anything below about 3.40 it adds a lot of heat ot the engine and EGT's attempting to roll those big tire. Correct ratio makes a huge difference. Optimal ratio is 3.55 to 3.73 final to the ground after tires have been figured in.

-

Runs rough when warm, mixing diesel and oil

Warm engine with low pop pressure injectors can product a misfire or stumble. I know he changed injectors. I've seen injectors with low pop pressure do weird things. The funny part was the set I had this problem with was RV275. Only different was mine I had test the first time and they were barely 300 bar. I cleaned them up internally and ran fine for about a year. Then failed again with stumbling and misfire. I would look at having those injectors tested. If a injector is stuck open it would explain the fuel mixing in the oil. Also bad injectors can wash out the rings too. Hence whay I dropped the RV275 and when to +50 HP and got them pop tested and flow matched. Can't do that on Bosch stock or Bosch RV275. Those are just 6 random injectors picked off the shelf.

-

Yet Another Fog Light Thread

@Silverwolf2691is correct. The Fog Light style switch the knob pulls out in the parking lamp position or head light position. I skipped all that junk setup because you can only have fog lamps in LOW beam only. Hi beams the fog light are cancelled. My original setup used 2 relay and I had four 100w aircraft landing lights below the bumper. Two bulbs were lo beams and the other two bulbs were hi beam so the second relay got it sense from the fog lamp relay. The turn on relay got sense from the trailer relay. This setup needed a 20 Amp fuse to power this setup. Current setup still comes on with the parking lamps. Single toggle to turn them off. But I'm running 18w PIAA LEDs Driving Lights. Way brighter than my Morimoto HIDs and on in both hi and lo beam modes both. I'm only using a 5A fuse on this. I draw way less current for lighting. I had way more light than most here. There is nothing about old school halogen bulbs that hold up to any LED or HID lighting. Again the factory fog lamp only work on low beams. Living out here in the forest of Idaho you need lots of light. Not just lo beam with fog lights. Then for the daytime running I swapped out the turn signal bulb in front for switchback bulbs. With the parking lights on the bulbs light up white. But turn on a turn signal they turn amber and flash. When cancelled they return to white again. Shown in the parking lamp mode and camera shutter speed was enhanced to show the bulb clearly. With my Morimoto D2S HIDs I can cast light out both sides of the highway at least 20 to 50 feet. Then vertically I've seen tops of trees that are 50 to 70 feet tall. Now the PIAAs give a good patch of light out ahead of the truck to see debris in the road or even animal working there way to road edge. This truck has right at $1,000.00 worth of lighting... Again there isn't much out there that can beat this.... Selected D2S lens which have much wider path than the H1 Minis. https://retroshop.us/collections/custom-lights/products/2g-ram-hid-projector-retrofitted-headlights Selected driving lights because the cast length is longer than fogs. https://www.piaa.com/store/p/187-LP530-3-5-LED-Driving-Light-Kit.aspx

-

Head Leak

Yup. I've got a similar problem mine is leaking on the back side a bit near the cam sensor I've already attempted to tighten as much as I could with the gear case cover off.

-

Head Leak

If you wanna fix it correctly you'll need the gear case gasket. Then you would remove everything in front. Radiator, intercooler, etc. Now you would have to make a set of wooden dowels to pull the tappets up. Then pull the cam out and then the gear case comes off. Now you can re-seal the gear case properly.

-

Head Leak

I would use grey RTV to attempt to seal that.

-

Help, looking for comparable trucks for sale… insurance co is not even close

Just today I got a buddy I work with make a selling offer on his 2nd Gen 24V for 28,000. Twin turbo, edge tuner, I think he's running 150 HP injectors. 2 inch leveling kit and 35 inch tires.

-

Truck randomly dies. Please help, pulling my hair out, and loosing sleep!

Taught you well being you just told my secret.