Everything posted by Mopar1973Man

-

Water in fuel, light. Truck died on me.

The WIF sensor / WIF plug is sensitive to just the water touching the contacts. All you got to do is blow it dry and push dielectric grease into the plug.

-

Another quad - mpg question

Back in the day I found that if you want to get good MPG you had to limit your speed to about 55 MPH. Above that the engine load was too high and stripped off the cruise timing. Being the Edge Comp basically adds timing on top of stock. With the Quadzilla you set all your timing yourself. Just like I'm finding out on level 2 your completely stock fuel (limited to 100%). Now any and efficiency is based on timing. Just "close" timing should get you to the 19-20 MPG range with winterized fuel.

-

Christmas pup

Ummm... @Wet Vette is right now on the floor with Ruby and she already is getting the concept of fetching a tennis ball. She runs after it and brings it back a few times but she is already chasing a tennis ball on the living room floor.

-

Another quad - mpg question

Yup. Zero smoke emission.

-

Carrier bearing shot

Same here I would rather force clean grease in and push the dirty grease out. Be careful that you don't ruin the boots on the tie rods and track bar pushing grease out. You don't want to create a hole that water and grit can enter.

-

Christmas pup

Called lazy loading. This delays the photo to the last second. This is so the page renders quickly but if a photo is in the veiw window then it loads the photo last. All other photos not in the view area those are not loaded till you scroll over them. Then it loads the photos to the page when needed. Instead of burning massive bandwidth to render a long page. This way the pages load faster and only burn what is needed for that viewing position of the browser.

-

Manual Fuel Pump

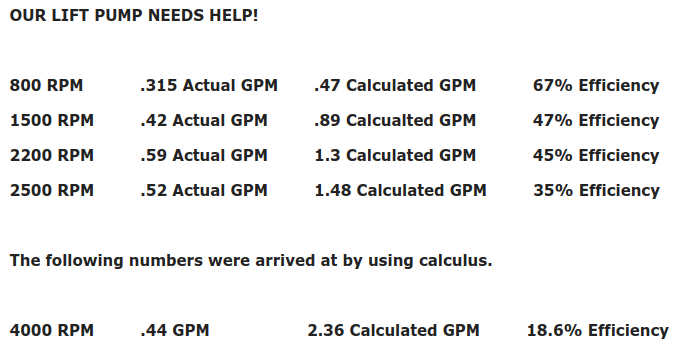

I would have to say more so Cummins. Still in all the mechanical pump did poorly for volume. Here is the article on the mechanical pump and how poor they are... http://www.torkteknology.com/technical-article-1-cummins-lift-pump/ Hence why most pull the mechanic pump off and install a FASS or AirDog with increase pressure spring for the P-pump requirements. Kind of hard to compare stock Cummins lift pump of mere 2.36 GPM (calc) or 0.44 GPM (actual) to AirDog or FASS at 150 GPH (2.5 GPM actual)

-

Crisis Proportion or Covid Craziness.......

Being away from people is super simple for us here. I'm 15 miles from Riggins, ID and 20 miles from New Meadows, ID. Now being out here and working from home makes it better again don't have to mess with people. Now so far like yesterday I stopped in my buddies shop to have my tires rebalanced on the Cummins. Steve has been through the COVID-19 also his wife and son all went through the infection he told me is like a nasty chest cold and flu. 2 weeks later he's doing good. Steve never had any hospital stay either. Eileen's @Wet Vette daughter (Jessica) had got the COVID-19 as well again like a nasty flu bug. Jessica's ex-husband that was caring for there son they both got it too. Again after 2 week they done and over it. I will admit she was spooked a few times with breathing problems and every time the hospital sent her home again. She was was check for fluid on the lungs but she never stayed in the hospital. Now around home, I never wear a mask even in Riggins ID. No need. But in McCall ID mask is required. Lewiston ID mask is required. Boise mask is required Required. Ontario, OR mask is required. I just do the basics, keep my distance from people, wear a mask while in larger crowds, and wash your hands.

-

Another quad - mpg question

With winterized fuels this winter I'm been floating about 18 MPG. Dec 29 - 18.11 MPG Dec 26 - 18.29 MPG

-

Another quad - mpg question

Just at idle in park or neutral and 8 to 10% is good yet. When it hits zero engine load and the RPM is higher than 800 RPM. Your injectors are done.

-

Carrier bearing shot

I'm like yourself I prefer grease-able parts. Not like I'm going to jump through hoops for it though. My ball joints are only upper grease-able but since I've never ran oversized tires I'm up to 200k miles and counting on this set of ball joints. U-joints are another story being the bearing cup typically fail to water / salt failure for me by spring I will of wiped out at least one u-joint in the rear shaft. Carrier bearing on my truck was more so the rubber failing and the shaft had one bad joint adding excessive vibration to the cab. I looked at this way it already cover like 200k miles back when I changed the carrier bearing last time. With all the salt and water I'm going to be look at changing again soon. Like my front wheel joints (U-Joints for the axle) I changed the first set at 350k miles. The problem was it took over 60 tons of pressure to break the caps free on the passenger side shaft. The driver side shaft took me 4 hours of beating on the caps to remove them. I learned even if the part is still good at hundreds of thousand miles later it might be a good though to just replace it because it will be well rusted and locked in place and nearly impossible to remove. Just consider I do brake jobs every +200k miles. No joke, not a typo either... Everything on my truck typically last a good long time.

-

Christmas pup

We were all sitting around the bedroom last night. (Breck and Jacob, then Eileen and myself) and talking about the pup we see small amounts of the Border Collie. Mostly the Chocolate lab in this pup. She is extremely smart. She is only 7 weeks old and already whining to go out but not quite understand to go to the door yet. Getting there. She is about half and half to respond to her name. More so whistle she comes. It's time for a new pup anyways I' lost Diesel two years ago. I see a very intelligent dog that is going to be sucker for water. Opps there is a about 2,000 gallon pond out back I'm sure as that dog grows up and spring gets here we will have troubles keep her dry. Oh yeah the fetch idea she has down already but the return is kind of like "I'm busy Dad I'm killing this tennis ball, Grrr!" She has a good health appetite, sleeps often and plays hard when she gets up. Nice to hear that little bark come out that tiny body. Or when you roll on here side kind of pinning her down and she growls back at you, fighting back. Heck I've already had her draw blood on me with those needle teeth.

-

Is there a "recirc" for heat?

Yes I've got grill inserts I bolt on in the winter but I've been forgetting to install this winter. My engine oil temp is now as low as 158 to 162*F which is getting to cold for my liking. Coolant is 188 to 195*F. MPG is down about 18 MPG without the winter fronts. Engine needs more heat to light the fuel off properly. My winter front does not interfere with the radiator or the intercooler. If the coolant temperature rises too much the fan can still lock and pull the heat out. Same with the intercooler if there is heat generated the fan can still cool the charge air without a huge loss. Majority of the grill face is covered and the direct cold is not blowing direct through the face at 65 MPH. BHAF typically gains me about +10*F after the grill is covered. MPG should rises again.

-

Care to share Your Most Horrible Vehicle Repair Nightmare?

Ok I can toss another I've seen. Working with one of the shops I was hired at and customer requested for a 2 inch leveling kit installed on his Ford. I was there and helped install the leveling kit but now the track bar wouldn't reach so the mechanic used a big come-a-long to pull the axle over in place to fit the old track bar. Serious thrust angle screw up and should of had a adjustable track bar. Something I'm backing out of now. Russ my landlord for my second shop is know for hitting salvage yards for replacement parts. I've seen way too many used transmissions that lasted a short time. Get the donor transmission out and drop the pan in the fluid could be black or contaminated. I even told Russ no more of salvage parts because I don't want to stand behind a gamble. Being one truck that he owns I shoved 4 transmission in and finally Russ blew the engine on that Chevy truck.

-

Manual Fuel Pump

Because they total screwed the pooch on that pump. The pump actually only pumps as the piston returns back out ot the cam so at 3,000 RPM that old 12V mechanical pump is only 10% efficient. Lower RPM's it does very well but at faster RPM's the efficiency drops fast and hard because the pump piston can 't return fast enough. Hence why guys that truly race 12V don't run the mechanical because it will starve out the p-pump. Daily drive those are fine but not good for any type of racing or high RPM uses. The cam pushes the pump plunger in and it pumps on the return stroke so if the cam is spinning too fast it only hops on the tip of the lobe being that the return spring is doing the pumping till the plunger makes contact with the cam again. As for the first gen the fuel pump is not high enough volume rate and only produces about 4 to 6 PSI total. This why the 1st gen was dropped because the volume of the lift pump and the limit of VE pump was good enough to keep up with HP. So the p-pump came out.

-

Crisis Proportion or Covid Craziness.......

- Trac-Loc Clutch replacement

One of the few reasons I love my standard open diff only one wheel spins per axle. Still keep my traction. Last trip back from Lewiston coming up Whitebird I felt the rear tire slip a bit but she kept tracking straight on.- Crisis Proportion or Covid Craziness.......

Personally I don't see masks doing anything. After a year of wearing them what I found is cloth or paper once they as wet from your breath just working or walking its no longer filtering. Im breathing around the mask typically fogging my glasses more so and making me blind. This makes shopping hard trying to she through fogged glasses. It also makes you tried because your oxygen level drops a bit more under working conditions and damp masks. Keeping my distance from others and washing my hands is priority.- Christmas pup

Well @Jthor was playing sneaky and left for day ride... When he returned he picked our new family pet. Named Ruby. She is Chocolate Lab and Border Collie. Ill love having fur babies.- FORD - For Only Retarded Drivers

Does matter what kind of vehicle. Typically I see either Red vehicles drive slow and like a F.O.R.D. Then the Ford owners are just as bad. Leave late, drive fast and reckless. That is one of my things I would rather leave early and take my time back down the cruise and just relax. I typically set about -2 MPH lower than posted and just chill out. Dodge, RAM or Cummins owners typically are very polite.- Care to share Your Most Horrible Vehicle Repair Nightmare?

Well I can roll back time. Back to my 1972 Dodge Power Wagon (4WD). My previous truck I did all the things a pup would do. Oversized tires and lift kits. Managed to tear up the wheel joints over 4 sets of wheel stubs damaged. Wore out 3 steering boxes 2 I've rebuilt myself. Suspension failures tie rods and ball joint issues stemming from lift and over size tires. I turned around and trade both my 1972 Dodge Power Wagon and Mom's 1976 Dodge Power Wagon in for trade in. I gave Mom the 1996 Dodge Ram 1500 to drive at that time and then took over the 2002 Dodge for all the work load. Ol' blue was so hard to get parts for I ran it till I couldn't get parts any longer. Axle parts for that partial truck was a strange half year axle that was rare with front drum brakes. Sorry for the poor quality photo but that the only one I've got. This was after pulling all my oversized tires and lift kit out and sold them. Then Mom's 1976 Dodge Power Wagon (727 Auto, 4WD)- Manual Fuel Pump

Just wait till the day and the return tee starts to leak air. Oh the sealing washers at the back of the head are leaking. Crossover tube o-ring failed and you now lost prime you not starting and it can randomly happen. I've seen it happen even on my truck which I see the fuel pressure fall flat to ZERO as the electric pump tries to reprime. Mine will start again. But mechanical pumps will not, kind of like when the stock block mount pump dies. No different.- FORD - For Only Retarded Drivers

Mine happen to be the Ford people coming from Boise or Lewiston crossing paths or they are coming for the snow in McCall, Idaho. When I pay attention to license plates you can see then next one is from a big town. Idaho list it registered county as letter number combo. Like most of my plates are Adams county (2A) but I got a few Idaho county (I) or Valley county (V). I'm looking for (1A) plates for Ada county (Boise). C plate (Canyon County). N (Nez Perce County) Lewiston Idaho. So in all the ownership of my truck (425k miles and 18 years) I've never had a speeding ticket, never been in a traffic accident, and one of the safetest drivers out there I've dodged many close calls and pulled off the impossible. Missed a head on at 55 MPH on ice and managed to get stopped safely off the road. @Wet Vettewill never forget this one she was there.- Another quad - mpg question

100% is true stock. 143% is equal to the 150 HP (7 x 0.010) I'm running.- S472 over Hx35 Sizing Options- Another Conversation on Compounds

I would suggest calling DAP and asking on options for your current injectors. 7 x 0.009 isn't really all the big. I'm still running 7 x 0.010 with my current single turbo. Too big of turbo you'll never get it to spool. I've seen this once where guy use to big for the second and it never built boost and he was building on 7 x 0.0085 injectors (+75 HP). - Trac-Loc Clutch replacement