Everything posted by Mopar1973Man

-

Time for New Injectors, will 7x10s be ok with stock turbo

Minimum pop pressure is 293 bar and its time to replace. This is why I don't like aftermarket injectors typically set below 310 bar which is stock. Then aftermarket builders know they can improve flow but at a cost of shorter life span. Hence why I popped at 320 bar, idle is 7% after close 100k miles.

-

2001 Cruise Control Issues

Look at the VIN number chart and modify the new VIN to what you want.

-

Sheared fan pulley bolts???

Photo please... I wanna see.

-

Vp44 dead?

No longer capable of setting timing correctly in the given time. It will run still but the economy and power will be poor. Timing piston is more or less jammed and not moving properly any longer hence the code. More or less on a gas engine like taking the vacuum advance off a distributor and taking out the fly weights. Then set the distributor to a retarded timing and drive that. Power is low and economy is poor.

-

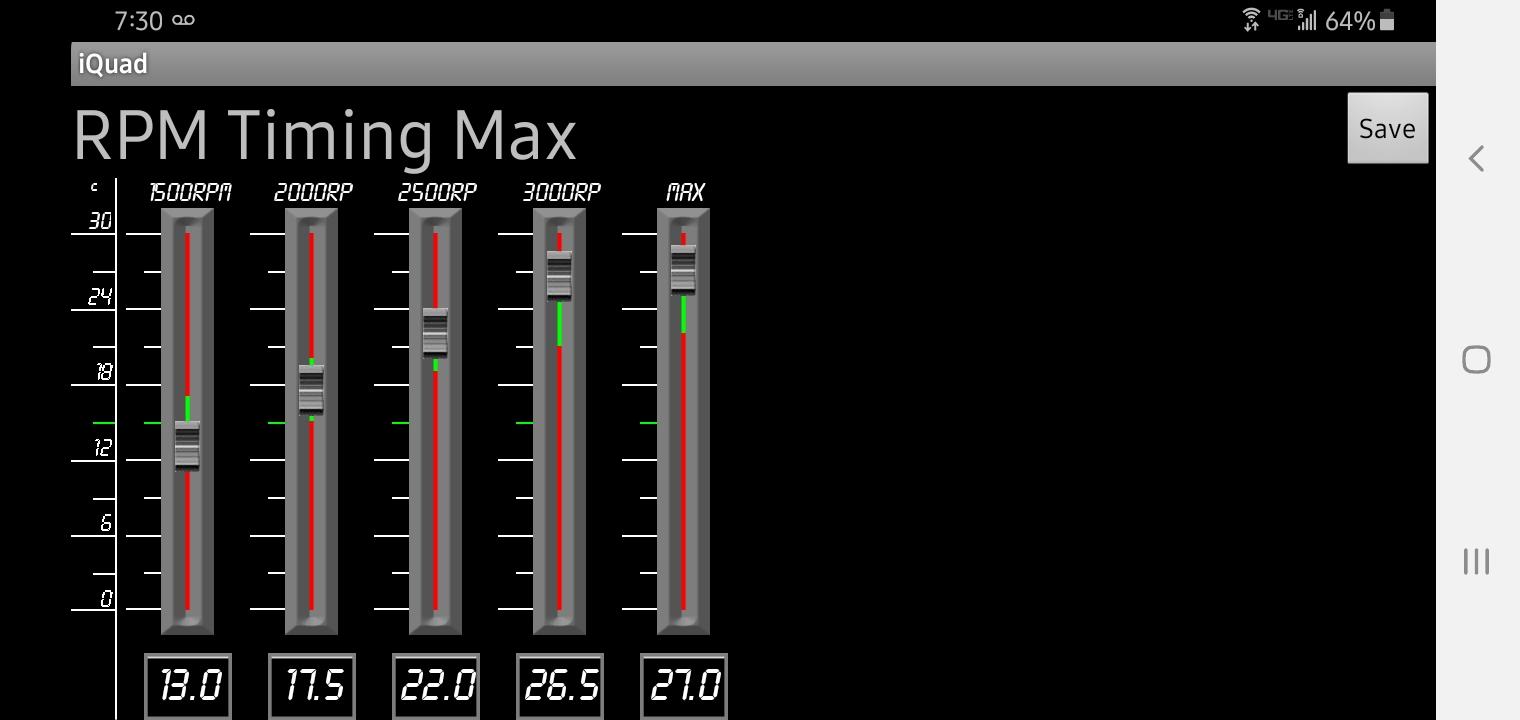

Need truck to be running better, less smoke

Post up your tune your running on the Quad. I'm behind you with 150 HP injectors and run completely clean. The biggest factor is too many are trying to build low down power but tend to be too advanced in timing on the 1,500 RPM band. As the cetane here is rising because winters coming I've been retarding timing because the bucking is starting to show up as cetane rises the ignition quality goes up, less timing is needed. To clean up smoke you need a good retard curve to spool quickly. Again people get to wrapped up in advancing timing they forget to retard enough to launch cleanly. Currently my economy tune is starting at 13° and work up +4.5 per band. I was so impress in this change that on level 2 yesterday climbing a 7% grade and managed to spin the tires free at mere 1,800 RPM and heavy throttle. This is due to the deep retard I built into the tune in the lower RPM range this place more flame on the turbine and spools quickly net results is the tires can't hold the torque... Now once the turbo is spun up then it kick back over to advanced timing and continues to power up more. Reaching 15 PSI of boost and the wire tap follows with more power and turbo is already spun good and just continues to build more power. I've got to ask another important question what sized tires are you running? This is a huge factor if power gets out or not. If your final ratio (after tires) is lower than 3.55 then your power is trapped in the driveline and transmission. Tire sizes and gear ratio make a huge impact on power and performance. Like Myself I've got 3.55 gears in and running 245/75 R16 tires. This comb creates a final ratio of 3.69:1 to the ground after tires. Hence my power is place to the road not to the transmission. Don't ask... I've manage to create enough power last year to break the teeth off the 5th gear at 80 MPH.

-

P0122

Timbo APPS has no voltage to set. It's fully mechanical APPS and no electronics. Stock APPS requires the voltage to be correct for the IVS (Idle Validation Switches). The voltage is used to tell the ECM if the driver is THROTTLING or IDLING. When it in the IDLING state the APPS sensor is igniored and the ECM software is used to set the 800 RPM. Once the voltage rises past the idle state then the ECM is told to listen to APPS sensor value. OEM APPS sensor has electronics in it to tell the ECM what to do.

-

Random Miss at idle and constantly feels like it’s detuning going down the road. 01 24v 6 speed

Boost fooler is not working correctly. CCD Network issues.

-

Turbo choice.

Rebuild kits are cheap. For RV275 injectors that HX35W will work fine.

-

Anyone paint or dress up their Cummins? Let's see some pics!

I never done anything per se to dress up my truck. The only thing I've done is kept my engine bay clean. When a leak occurs find it and stop it. Wash down the engine when I wash the truck. Lately I need to do that more really. Pretty dirty. Typically I don't bother with a bunch of paint or dress up. Just keeping it clean is just a big crowd pleaser for most. When you own a 18 year old truck and its still clean under the hood and in the cab. Most people are shock when I open that hood and there is a clean stock looking engine.

-

2001 Cruise Control Issues

Airbag light is most likely the clockspring in the steering column. Again the clockspring takes care of the cruise functions. It's a variable voltage. Say like 1 volt does one function, 2 volts does another, etc. There is 5 volts in that line but the cruise sends back different voltage message for each function. Transfer case is easy just remove from the truck and split the case open and seal the mating faces again. Then there is a front seal and a rear shaft seals just pull the out and replace. Make sure there there is no wore groove in the shafts. Fly by wire cruise basically the throttle signal is sent from the PCM directly to the ECM. No vacuum motor used being there is no automatic transmission with a Throttle Valve (TV) to pull. Since the only reason for vacuum direct cruise is the automatic transmission. Now if the PCM is the wrong one it will send out on the 4 wire plug. there is roughly 50 some odd software version per year for the PCM. Wrong software on just one module makes all kind of weird issues. Both the ECM and PCM should be matching years and should be matching VIN wise too... I know several have done swaps of modules but it has to be done right. I've used Auto Computer Specialist to get my PCM replaced after my alternator fried it. Provided me correct VIN number and even proper software for my year, make and model. They even have a harness repair there too so you could send in your harness and have it repaired like new!

-

Can someone help with factory height

Please do... Articles really do help a bunch of folk to just read what it took to make the upgrade or project...

-

Can someone help with factory height

Exactly!

-

2001 2500 Rapid Torque Converter Cycling

I would have to refer you to @Dynamiche's our site transmission guru. He should be able to tell us why the torque convert is cycling all the time on you. Jon Elford is a good guy. He's built my 46RE to be pretty bulletproof for 5.9L V8 gasser. Even when last winter my 1996 Dodge was dropping to first gear randomly he had the answer. https://mopar1973man.com/forum/173-dynamic-transmissions/

-

Thoughts on an electric fan?

Cold mornings (< 32*F)... Mine will act like it locked up for about 30 seconds and then unlock and the oil moves to the reservoir in the hub. Normal spring,summer and fall it just spin loose. Still factory OEM fan clutch and still fully locked typically by 210*F. The rest of the time free spins.

-

Is this clutch engagement normal?

Air in the hydraulic system? Have you tried to bleed the clutch out again. Pull it all out as a full piece. Then hang the reservoir high and let it all hang. Now quickly press the clutch slave in rapidly and hard and hold for a few seconds. Then slowly release the pin back out. As you press it in you quickly pushing air upwards to the reservoir to get out. Then when you pause you allow the air to continue up as far as possible. Then slowlly letting out the slave pin allows to reload the slave cylinder without pulling air back down. Do this about 5 to 10 times and you should be ready to install again and work better.

-

Can someone help with factory height

The whole thing behind the rake is so you can carry a load without your headlight shining in the sky because its swatting in the rear. Any leveling kit you put on the the rear will sag down when loaded. I've been up close to the 26,000 pound limit on my registration of my plates. Here I am with GCW of ~17,300 pounds, and about 62 foot long total. Sitting level. (Nevada 2020) Another... My truck is always level towing. No need for lift in the front. Level hauling 2 cords of firewood... Another hauling hay... Five 1-ton bails that's 10,000 pounds just in hay on a bumper pull car trailer.

-

Heater core replacement coming soon. Anything else?

Vacuum controlled. The door motor is on the passenger side near the kick panel you might see it. You would have to apply vacuum to the side that pulls the door closed.

-

Quadzilla tuning

Mopar1973Man replied to 24valve gear jammer's topic in 2nd Generation Dodge Reliability / PerformanceThere is a bunch of pre-made tunes in the download area. Take a peek...

-

2001 2500 Rapid Torque Converter Cycling

Ok. The only thing I can think of output speed sensor is goofy. Possibly rear axle speed sensor.

-

2001 2500 Rapid Torque Converter Cycling

Alternator can generate any power with the field lead unhooked.

-

Quadzilla tuning

Mopar1973Man replied to 24valve gear jammer's topic in 2nd Generation Dodge Reliability / Performance

-

Truck bouncing with load

I was talking to a gent today about this and he was suggesting a air bag system for people that tow heavy constantly to have a independent air controller for left and right in the cab. Makes the best towing when you long hauling. You can adjust on the fly to smooth out rough patches. For people just once in awhile.. Shock would be the first stop. Kind of like myself I tow but not daily. Hence why I don't have air bags...

-

Can someone help with factory height

Not to hijack... Matter of fact. I just got me a local guy (J. Stewart) that is retired and willing to do alignments and custom alignments for lifted Dodge Truck and he lives right in Riggins, ID. I told him if I had any that needed help I would send them. He dropped off a Chevy A/C for me to look at... His story was of a Chevy car that had alignment issue. The owner was a very obese lady. He was the only one that was capable of customizing the align for the offset of weight to make it right. All the shops were using factory numbers which won't work. Same applies to the truck when you lift you change everything so you have to customize the alignment because it no longer factory height.

-

2001 2500 Rapid Torque Converter Cycling

Personally I think it still the alternator. The only thing I can suggest is measuring while your driving and see if the AC noise is rising while under load. The only thing that causes the AC noise is a alternator. If you pull the field lead and test drive again it should be normal.

-

Can someone help with factory height

How I know this I managed to destroy my 1972 Dodge Power Wagon with a lift kit and manage to eat ball joint for lunch, tie rod failures very common. I made myself a promise I'd never lift or modify my new truck. Ever since I made that promise I've NEVER had any steering issues. Keep the geometry correct. In a mere 100k miles I managed to ruin that 1972 Dodge to the point I use it for the trade in on my current 2002 Dodge.