Everything posted by Cowboy

-

fan clutch

Many have done it without issue. So yeah, it seems to work. Nice thing about it is both seals are offset from the stock one so both have a fresh place to wear to the crank.

-

Which vp44

Agreed. I had a '99 blow an intercooler boot. Had about 30k lb's strapped to it's butt and it was SOOOO LAME. Had to crawl in 1st 4L just to find a safe place to pull over. So yeah, it forced it into limp mode.

-

trreed's upgrade thread

Weight distribution is everything! I do need either some airbags or overload springs for the '96. It'll probably get swapped to a dually over the summer for hay hauling.

-

Which vp44

notlimah is correct. The steering is probably far too toe-in. If you park the truck straight, then eye ball the front tires, you should be able to tell.

-

Cracked exhaust manifold

When I checked mine, 4-6 was about 50°F warmer and had (IIRC) 5-10 psi higher drive pressure at WOT than the front 1-3 cylinders. This was with a fairly stock HX35 which has a twin scroll turbine housing.

-

HELP NEEDED ASAP

If the leak is coming from the piece he is holding, you can get new DV holders. If the leak is from the part still bolted to the pump, you'll need a new IP or send yours to Seth Farrell @ Farrel Diesel Service. Or some other Bosch shop.

-

Front Axle CAD Vacuum Actuator to Manual Posi Lock

The vacuum switch that comes with a BD exhaust brake would be perfect! It's a 4-way direct acting servo controlled valve. I had the number, but don't remember it now. Either way, I was looking for a replacement and couldn't find anything. Maybe you could contact them or pac-brake and see if they'll sell one to you.

-

Front Axle CAD Vacuum Actuator to Manual Posi Lock

You know, there are other options... You gotta go slightly custom, but the outcome is almost factory looking.

-

No 4wd

Well yeah, no one ever needs 2wd low. A nice-to-have... very much so. Either way it's your rig and is up to you. You seemed to be extraordinarily passionate about your non-CAD prefferences, so I thought I'd throw the idea out there. gassernomore, best way I've found to find a vacuum leak on the 4x4 system is to just throw it in 4x4, grab the black line off the CAD actuator on the axle, and blow into it... hahaha you'll hear it leaking from you leak.

-

No 4wd

Nice thing about having the CAD is easy 2wd Low. Then again there are still workarounds without going for manual locking hubs. Mike, if you really despise the CAD in the 96, just disable it. The collar will stay locked and it will be like it was no longer there. I'm half tempted to do this, but haven't had any problems with the 4x4 of yet that would warrant it. And like said, I don't really mind my front shaft not spinning all the time.

-

Grid heater manual control...

WE NEED FANCINESS!!!! If that means burning the truck to the ground, then it was worth it! Lol Seriously, if you really want it, the right battery disconnect switch will do fine. The couple dozers over here all have a battery disconnect switch that all the juice goes through, that includes the starter. Another option is something like this: https://www.amazon.com/Stinger-SGP90250-250-AMP-Circuit-Breaker/dp/B00TPKZV82 Even doubles as a circuit breaker.

-

Grid heater manual control...

Fwiw, there must have been a wiring change somewhere between 99 and 02. The 99's had the ECM switching the ground. If you can disconnect the big lead on the relays, it sounds like you should be able to fake the ECM out with a resistor. With the right switch, you should be able to pick between Manual On, Auto, and Manual Off. Frankly, I'm fine with my PCM controlling the grids but can understand someone wanting manual control.

-

High Idling W/Dead Pedal

Yep, it'll do it with the engine hot at 80°F. I totally forgot about the battery temp sensor. I'll have him test it and see what happens. Thanks again!

-

High Idling W/Dead Pedal

He replaced the alternator with a parts store one, but did have them check it before installing. I know, not ideal, but options are kinda limited when you're on the road. So far so good, dead pedal hasn't come back, and he said his mileage has gone up as well. He mentioned that he's been having a problem with the grids cycling when the engine's hot, it's been doing this for almost a month. Like if you park it for 20 minutes and start it back up, it will cycle the grids. He already replaced the intake temp sensor, and he said his overhead console and engine coolant temp appear to be reading correctly. Any ideas? I'm kinda of the mind that the alternator scrambled the PCM in the same way it did for the APPS. Is there any way of resetting it other than bringing it to a dealer to be re-flashed? Thanks again!

-

Nv4500 filter

That is correct, the deflector must be pointed up.

-

High Idling W/Dead Pedal

Thanks Mike! I let him know. We'll see how this second reset works out.

-

High Idling W/Dead Pedal

Howdy guys, Paps truck is down and I'm currently 1600 Miles from either him or the truck. So we could use y'alls assistance. Rig specs: 1999 Dodge 3500 NV4500 4x4 with 3 year old Timbos APPS Truck was running fine, then it started to high idle on startup to about 1100 RPM (He doesn't have a high idle kit) no delay, it just went straight to 1100. Then a day or two later he started it up to find it also had dead pedal stuck at 1100RPM (in a Walmart parking lot lol (Thank heavens for Torque!!!)) He did some research on the issue, and decided to try and reset the apps doing the 30 minute battery disconnect thing and then pumping the throttle slowly. Apparently that fixed the issue for a couple days, but now it's high idling again (didn't check for dead pedal). So what are all y'alls thoughts? If the APPS was bad, I'm a little confused as two why a reset would fix it. Last I spoke with him there was no check engine light. I forget if he checked codes or not. My current thoughts are to see if he can unplug the apps and see if that will make it idle. And then do a visual check to make sure everything is installed as it should be and the apps isn't dangling or something. Next would be checking the APPS voltage and Idle validation switch (Anyone got a good link to what it's suppose to be at?). Though I'm not sure if this is an option due to his limited tools out there. Thanks guys!

-

Nv4500 filter

Like DieselFuture said, you can only run one filter setup, and it should be on the passengers side. Reason for this is the filter needs oil to flow through it to work, so to get this flow, they use a deflector to catch the oil that's slinging around the gears. That is what this lip does here. It works like a hood scoop, in that it grabs the passing oil and diverts it into the filter. That's where the oil goes in, and in order to come back out it needs to go through the filter. That's why it should be on the passengers side, that way the sling-off from the gears is going the correct direction. Because of this, you can't run two filters, as only one can utilize the gears sling off. The second filter would not be doing anything.

-

Air filter

If you're wanting to clamp the filter on your intake pipe, you'll wanna make sure the flange diameter is the same as the outer diameter of the intake tube. So if you're intake tube is 5", you'll want a air filter with a 5" flange, like this one. https://powerdrivendiesel.com/product/power-driven-performer-air-filter-5-inlet/

-

Friday Funny.

Fun Fact, Big foot is a buddy of mine and actually dwells in California. He has a 20 shoe size, 7' tall and ain't nearly as hairy as they say.

-

Air filter

You'd have to go out and measure to be safe, but it's pretty common for 5" steel intake pipes to have an outer diameter of 5".

-

Verifying HX35/40 turbo size

Do it. Then send it to me! If I had the machining ability to throw a he351 compressor on a HX35, id have done it by now. I have a feeling most of the he351 success comes from the compressor wheel.

-

Verifying HX35/40 turbo size

Please do! I'm curious what you find. If yours is a 60mm, you'd be the first out of a dozen or so people I've talked to that measured one and got that number. If you're familiar with Will at PDD, I talked with him and he said that he's measured dozens and only ever got 58. I personally sat down with a HY35, HE341, and HE351CW, took the turbine out of each of them, sat them side by side and they were all identical, probably have the same part number. I've always wondered where the 60mm thing came about, I must have been Holset themselves. Just doesn't appear to be so by forum measurement standards.

-

Verifying HX35/40 turbo size

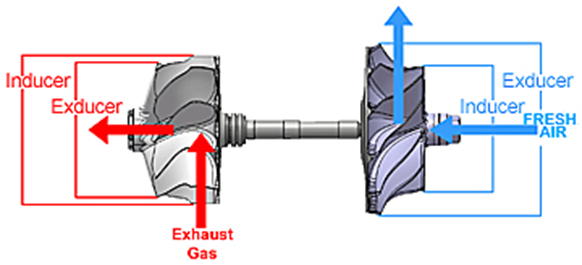

Yes the blades are curved, but in todays turbos that's referred to as a straight blade turbine. The inducer side of the fins are parallel with the shaft. Looking at AH64ID's HE351 pictures above, you can see the the inducer part of the blades are curved. The straight blades make more turbulence which helps with spooling, but limits top end do to increasing the restriction. I could never keep the inducer/exducer straight either till the obvious hit me like a brick. Inducer = Intake side of the wheel. Excuder = exhaust side of the wheel. The HE351 is actually a 60/58/9. Somehow they've managed to take a crumby HY35, redesign the turbine housing and compressor wheel, and turn it into one of the best sub 500hp options to date... The Stock HX35 Turbine wheel specs at a 60/70mm, but the inducer typically measures a little shy of 70mm, so it sound like you've got a stock HX35 turbine.

-

Verifying HX35/40 turbo size

I've always been curious what drive pressure is with a hybrid like that. You've got a tight twin scroll 12cm housing with a small straight blade 60mm turbine. The he351's do pretty decent, but they've got a curved blade and a single scroll turbine housing. Speculations. Unless, someone were to measure it.... ????? lol