Everything posted by TFaoro

-

Ijection lines so tight.....

@Me78569 or @Mopar1973Man can one of you guys move this to the correct section?? I would just try to use a different face, or get an line wrench to tighten and loosen them.

-

7x0.0085 +75HP SAC Injectors from DAP

Normal with bigger injectors. I'm guessing it's the ECM overcompensating and undercompensating. As you go bigger with it'll lope more to an extent, then remain the same.

-

Advice on Exhaust Manifold/System/Brake

1 - If you know you're planning on a turbo upgrade, go with the "in line" exhaust brake. It'd suck to buy a turbo mounted brake and have to buy another in the near future. 2 - I prefer the stainless, but you should be fine with that 3 piece. It shouldn't crack like the stock one. Go with the divided gasket because the manifold is divided. 3 - I don't see the need for stainless. It depends on the quality of stainless too - low grade stainless will rust too. I personally painted my exhaust with 2000* paint and it's been holding up well, although I doubt it would rust quickly without paint. I've yet to hear of any of the aftermarket exhaust companies using a muffler that keeps the 4" drone down very well. Especially with an aftermarket turbo.

-

Teardown and Rebuild

Picked up some parts to fix the girl. Injectors from DAP showed up. There are 3 new nozzles. Pretty disappointed they didn't put caps over the tips though. Baffled tappet cover with two -16 AN fittings (3/4in) 10ft of 3/4 hose and 8 ft of 1/2 hose Stant oil cap drilled and tapped for a 1/2npt fitting. I'll run this to make sure the engine will be okay with these 3 breathers. If all is good, I'll probably pull the valve cover and have a 3/4in fitting welded in. Now finding time to get home and fix the friggen thing. I don't want to pull the effin pump for the 3rd time in 10 miles!!!!!!

-

Exhaust manifold

-

Exhaust Brakes and head gaskets

Correct. 12V motors came with weaker springs and have a larger surface area per valve.

-

Teardown and Rebuild

If mine didn't show any signs of wear I would be content.... Being this isn't the case and I'm using it with used tappets I can only assume it'll start to wear faster. If the guys at Infinite recommend on I think they can be trusted.

-

7x0.0085 +75HP SAC Injectors from DAP

Boost is NOT a good reference for cylinder pressures. It depends on timing, boost, temperature, etc. If I were Mike I would at least check one of the head bolts to make sure the gasket hasn't seated over time. Studs wouldn't be a bad idea, but when money is tight ya gotta do what ya gotta do

-

Exhaust manifold

EGT's I liked my 3 piece other than it had a defect in the sealing surface and I had to have it machined when I sold it. I really really like my stainless. Yes they cost more, but to me it's worth it.

-

trreed's upgrade thread

I HIGHLY doubt that at 500 miles on a new pump and 20 miles from the pump that I pulled would cause it that quickly. First place I would start (before you meet Nick) is fix the GARBAGE battery cable ends, clean all grounds, remove all electrical connectors and clean / fill with dielectric grease, and open the wiring to make sure you don't have a chaffed wire between the ECM and VP.

-

Teardown and Rebuild

It's not like they tried to deny it was their fault or say I did something wrong. They fully accepted responsibility when they said it doesn't happen "often." I was at least expecting them to ask for pictures so they could figure out what went wrong, or ask for the cam back so they could know where one of their processes went wrong. They just didn't seem to care.... didn't seem surprised in the least bit that it happened. I will be recommending against their products from now on.

-

Teardown and Rebuild

I could send a sample in now, but it'll have assembly lube, probably a bit of fuel, and some other garbage in it from the swap. I called Hamilton and they were less than helpful. I told them how I installed it, how I had ensured clearances were good etc. etc. All he had to say was "well this doesn't happen often. I can get you a new one for $450" - Like hell I'm going to pay another $450 after ruining one in 25k miles.

-

Teardown and Rebuild

No.... This oil change was going to be my first. However, I will definitely be doing them at every oil change now.

-

Teardown and Rebuild

I'm not sure what's going on with my PM's right now. I think I need to delete some.... I apologize, but I have already sold the TST. It really is hard to believe until you do it yourself. Other than the cam, everything in my motor is healthy as can be but always idled stupid. Now it idles so smooth it's weird!

-

Ground posts and preservatives

At my parents place we have a couple of round wood posts that get all of the old oil filters placed on. That fence has been up since before I was born (23 years) and shows no indication of rot. Oils are good for keeping the moisture out of the wood, but even if you choose not to I think it would still live a fairly long life if you use the gravel around the wood. Like the others have said, moisture can be the enemy.

-

Pre or Post for EGT probe

Pre-turbo gives a better indication of combustion temperatures and the heat the turbine wheel on the turbo is seeing. If you want to run a pre-and post, I think that would be fine. If you are only running one, I would strongly advise you stay with pre turbo.

-

7x0.0085 +75HP SAC Injectors from DAP

I hope they sent mine with crossover tube O rings as a couple of mine are leaking bad. The "removal tool" is literally a nut that is supposed to thread onto the tubes. I don't think the nut will work though because the tubes are recessed.

-

Engine Oil leak

Try to get a light and see behind the injection pump. It could be the tappet cover gasket back there.

-

CJ-4 vs CK-4 diesel oil

Where's the oil man @AH64ID??? I'm sure he can tell us everything we need to know about the new oils

-

What a day

That's sad to see.... I'm sorry for that happening. Steel can be bent back and replaced. As long as the drivers are okay, that's what matters.

-

trreed's upgrade thread

Fluke. They aren't cheap, but they last forever and are accurate

-

trreed's upgrade thread

Hmm I remember saying you should check AC noise "cough cough"

-

Teardown and Rebuild

The dowels get shoved into the tappets to hold them up. Otherwise you can't get the cam out Oh it's very nice to drive. I was FAR from having it dialed in correctly and the engine sounded 10x better than a healthy VP. Also made a ton more power with those stock injectors than I could have imagined.

-

trreed's upgrade thread

And for the low price of just $350 it can be all yours!!

-

Teardown and Rebuild

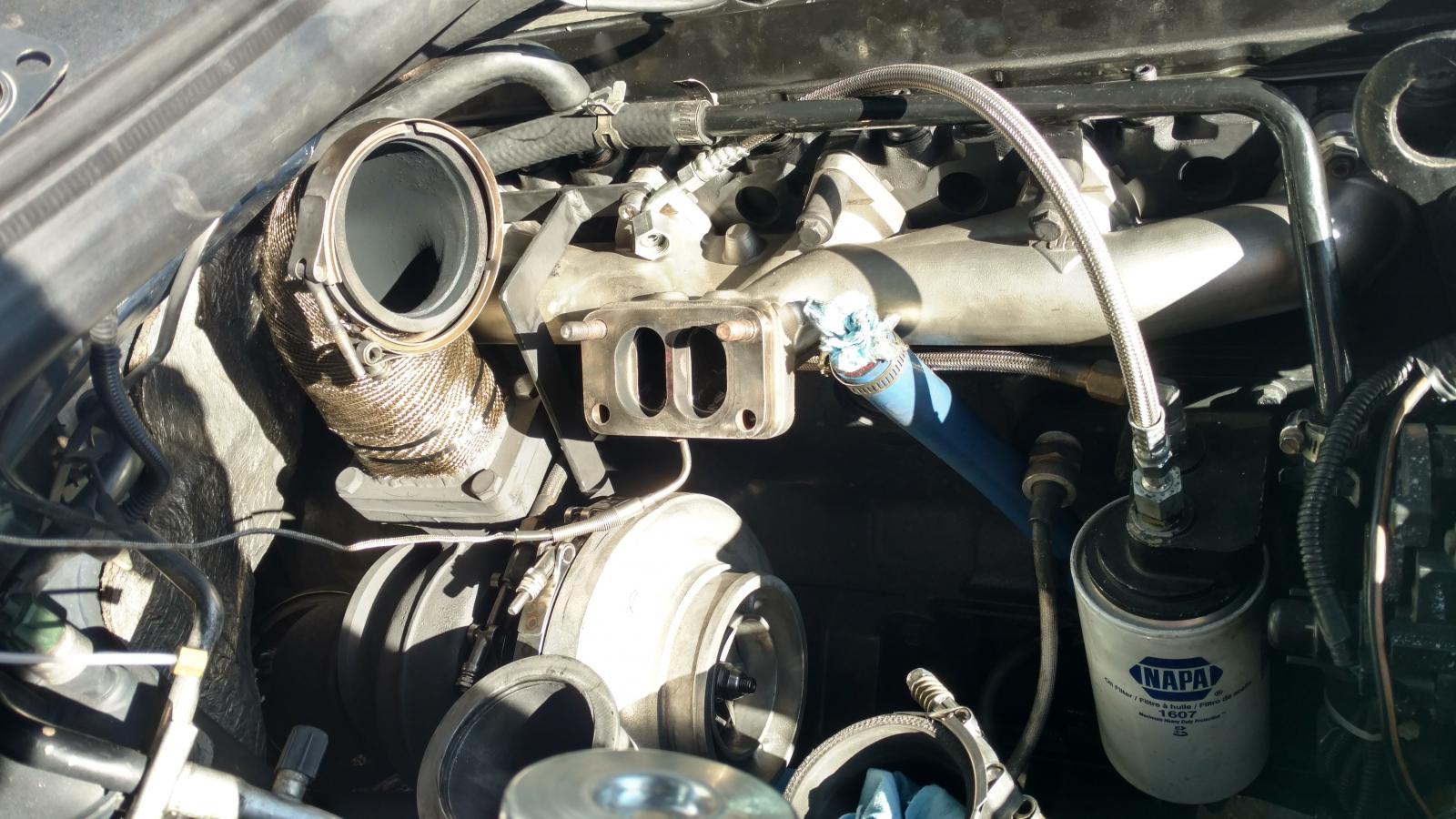

Teardown was pretty fast and easy. I got some POS dowels and #1 intake tappet fell into the pan later, but I was able to fish it out. Then I pulled the cam and that's where things got ugly. Only a couple of the lobes weren't worn down bad. I checked the tappet on the worst lobe and it was just fine, so that tells me the cam is a POS. I did hamilton's break in procedure, always ran their zink additive and what not so I put the stock cam back in it. My dad built an ECM mount since I have a 12v tappet cover and the ECM couldn't just be spaced out like people normally do. I put the case in, stuffed the cam in, and realized I forgot to file out the cam sensor adapter hold. So I pulled the cam back out, filed the hole out, put the sensor in, and stuffed the cam back in. I then put the pump in, timed it (pin timed to 14* then moved pump 3 holes on the adjustable gear to get 20*) I put the rest of the front together, pump lines, etc so I could start it. Then the pump was leaking around the O ring hole. So I pulled the pump out, went to Cummins, got a new O ring and put it back together. It leaked again after that, so after talking to Seth and Jacob I RTV'd it in the hole and it quit leaking. I made new studs for the intake horn until my tunnel ram shows up (@turbolvr you guys must be swamped with orders to be backordered that far!!!) I ran the AFC live hoses, wired in the shutoff solenoid, hooked up the APPs stuff and probably a bunch of crap I'm forgetting. I then took it out to drive and for some reason the shutoff solenoid keeps dropping anytime the truck builds boost or gets to higher rpm. It dropps at about 3800rpm or 40psi of boost. Whichever comes first. I even tried hotwiring the solenoid open with no luck. If anyone can give advice on this I'd love to hear it!! So I wired the solenoid up to drive it a bit. I had one small leak on the front cover where a bolt goes in, but I think I can RTV that to fix it. I got it on the highway and made about 60psi of boost with stock HO injectors :hehe: Took it back into the shop to find it puked over a gallon and a half of engine oil. I think it was the tappet cover, but I didn't have time to tear it all back apart and put it back together. So I left it at home and headed back to school. I'm going to pick up a billet cover, run a breather out of the oil fill, and possibly put another in the valve cover. Maybe @turbolvr has some advice on this?? So at the end of the day it's still a cursed pain in my a$$ that doesn't want to be reliable with a Ppump....yet.