Everything posted by Cronus577

-

VP44 info needed

I like it, my theory would be - It would still make 125mm3 of fuel per stroke due to the fact that the pump is untouched and the delivery demand for the pump is left the same. The only thing changing is the amount of fuel injected by the injector, which is completely mechanical and a computer wouldn't adjust for that hence why bigger injectors on a stock truck smoke so much. So the fuel per stroke would be a constant in this situation. With the overflow valve it would simply recycle less unused fuel with a bigger injector because the pump can still supply adequate fueling required by the injector demand. But we would need to know the amount of fuel actually injected on each injector and figure out how much fuel it injects per pop to get an accurate variable to make the mathematical equation.

-

1 EGT probe to 2 devices?

Haven't tried a torch. Pb blaster soak sprayed several times over 2 days while doing a compound setup and it didn't want to budge, now the manifold is upside down and would be difficult or dangerous using a torch now that the bung is on the bottom near the oil return for the small turbo

-

Fuel tank straps

No reduction of vibration could hurt, was under my truck doing the exhaust last week and I looked at the tank straps to make sure nothing was rusted, and I didn't see any type of vibration damper in between the strap and the tank. I'll be putting my truck on the lift tomorrow afternoon to do my DD clutch & built transmission install and can snap a few pictures for you.

-

Quad ADR BT Issue?

Had an issue with my iQuad not connecting, ended up uninstalling and reinstalling the app and it connected right away.

-

1 EGT probe to 2 devices?

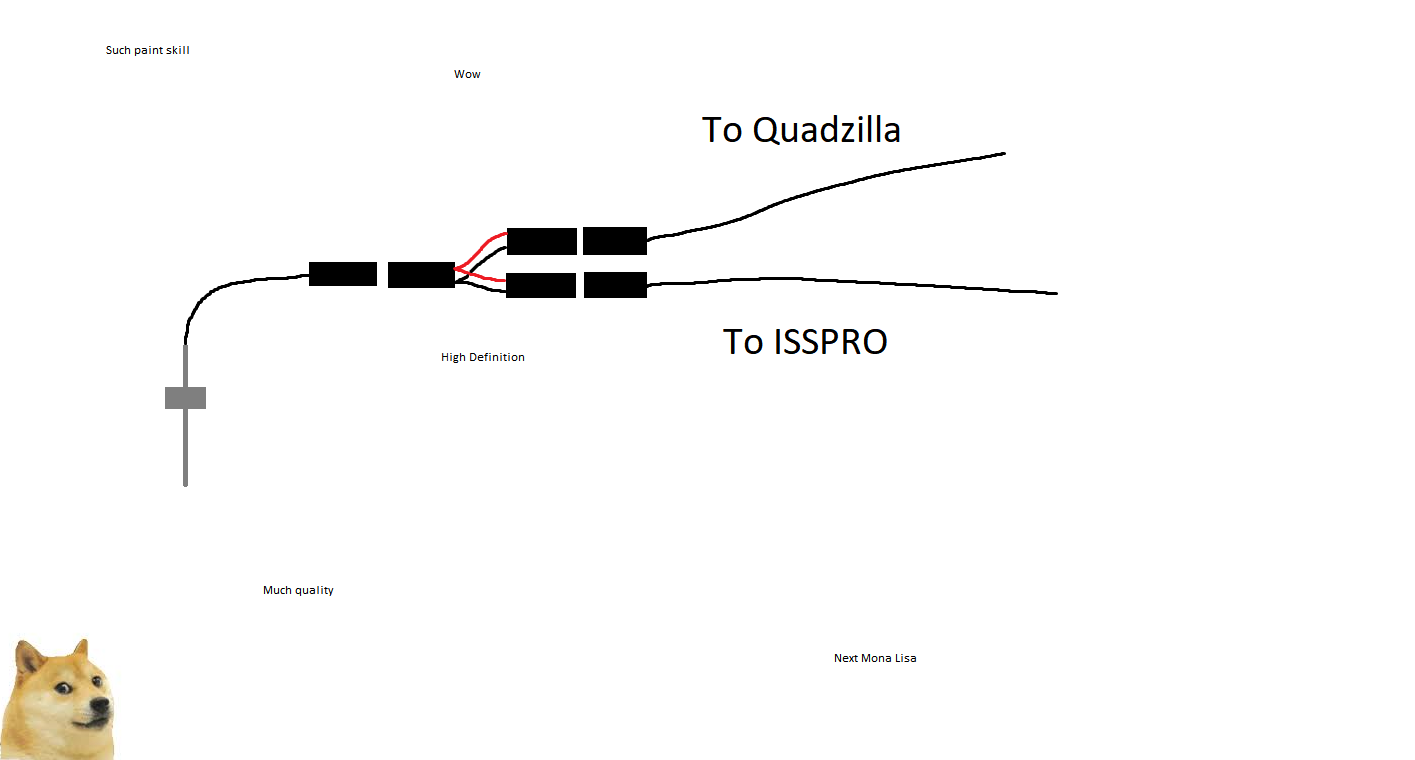

Like I said, I'll do some data logging and see if there's a big difference, I understand that adding some wiring will cause resistance which will cause the reading to be inaccurate, but how inaccurate would it be? I'll do some testing, if it's more than 50 degrees off i'll put in another probe.

-

1 EGT probe to 2 devices?

I can test it and do some data logging and let you know. I read on another thread this morning where one guy did it and his read correctly.

-

1 EGT probe to 2 devices?

Hmm, I have the EGT probe for the Quadzilla just in my parts box, I just really don't want to tap into this manifold considering it's almost $500. But if I run the risk of frying anything or misreading I'll have to bite the bullet and tap it. Would just have to get a tap. I'll put the Quadzilla probe on the back of the manifold to monitor temps for cyl #5&6 so it can backdown from more effectively.

-

1 EGT probe to 2 devices?

I'll keep that in mind, I wasn't going to cut into any preexisting wires or anything just simply make another connector. I might just do a couple of datalogging runs with the Quadzilla hooked up to it and get an accurate reading and make a Y connector and do more data logging to see if there are any changes. Hopefully running the connector in parallel won't give any odd readings.

-

1 EGT probe to 2 devices?

I would but i'm running a BD manifold and I'd like to not drill into it. It has 2 pre-tapped spots for an EGT/Backpressure gauge, one of which I'm using already but the other has a bung to plug the hole and after many heat cycles it's stuck in there.

-

1 EGT probe to 2 devices?

Hey guys, was wondering what ya'll's thoughts were on running 1 EGT probe to 2 devices. I currently have my EGT probe hooked up to my ISSPRO gauge so that I could monitor the temperatures easily, but I wanted to make a Y connector connecting the 1 EGT probe to both my ISSPRO gauge and my Quadzilla so I can datalog and use backdowns. Would there be any issue as far as voltage drop causing inaccurate readings or would I be in the clear? I drew a picture in Paint to show exactly what i'm talking about.

-

Boost questions.

Like @Me78569 said, need a boost fooler and I have one for sale for a 99'. You would also benefit from a boost elbow so you can change when the wastegate will open. As far as the stock motor, 45+ psi and you will start running into the territory of blowing the head gasket without head studs. 150k miles is absolutely nothing, My truck has the notorious 53 block with 355k miles and I push 55-60 PSI Get a boost fooler, and a boost elbow and push it up to 33-34 PSI. Anything more than that and the stock HX35 isn't efficient and you run the risk of blowing up the turbo

-

Engine squeak, NOT serpentine belt

Thanks I'll check to see if I have them somewhere. I did my injector change when upgrading to DAP 50hp injectors and made sure all those were on. But I took it to a company in town that "specializes" in diesels for the 50 to 100hp injector upgrade and I found 2 of the clamps in the back of my truck, I kept them thinking they were important for something. I just have to figure out where I put them because all of my stuff is in a storage unit. I'll check the lines and make sure they're all good to go, when I felt the lines for #5 & #6 I could feel a hard pulse going through them while #1-4 were pretty smooth. Hopefully these clamps fix the issue, would be crazy to me that such high pressure fuel could cause a metal squealing noise. I'll keep y'all updated.

-

Engine squeak, NOT serpentine belt

I thought it could have been something along that nature but now that i'm watching the video i'm tracking where the sound is coming from and when it transfer from one ear to another. I think it might be #5 and #6 high pressure lines. Considering I also see that one of the clamps is missing right at where the sound is transferring ears.

-

Engine squeak, NOT serpentine belt

Got a video, also went under the truck and listened but I can't hear it from underneath. It sounds like metal on metal screeching. Will be putting a Velair DD clutch and a built NV4500 in the truck this weekend so that would tell me if it's clutch or flywheel related. Video

-

Engine squeak, NOT serpentine belt

The noise is coming from about cyl 3 to 6. Its not towards the front of the engine. Looks like this might be some bad news

-

Engine squeak, NOT serpentine belt

Was sitting at idle in the parking lot before shutting off the engine. I noticed a squeak under the hood, I know my serpentine belt was squealing a week ago after hitting a big puddle and thought that was the case, so I popped the hood and had a listen and it's not coming from the belt. It's loudest on the driver's side around the valve cover. Is there anything under the valve cover that would make a squeaking noise, injectors, valve springs, could it possibly be the vp44? I don't notice anymore smoke than usual, loss of power, and there's no blow by

-

Hid retrofit

I went off of the instructions at 270* for 7 minutes. I didn't want to melt anything so I didn't raise the temperature, just left them in for about 13 minutes. Was able to get it off but not as easily as most of the instructions say.

-

Hid retrofit

Did mine as well. Not sure if the ANZO housings use a different kind of adhesive, but I followed the instructions on baking them and they just did not want to budge, took about 2 hours just to get both housings covers off. Definitely a huge improvement over stock though!

-

ECM oddity

Possibly, when I replaced the batteries to the red tops I made sure that the terminals and the contacts were cleaned. Tightened them down like I did this last time but I still had the WTS problem. Although with my EJWA and my new TIMBO APPS would only read 92% at WOT. Now with my Quadzilla it will read up to 100%. Electrical gremlins are strange. Hopefully the issue doesn't return but so far it's looking pretty good. Also just replaced my drum brakes and shoes along with a snapped parking brake cable. Never again, I'll pay a dealership to do that.

-

4 Inch Exhaust Needed!!!

Can attest to this, two muffler bearings made my truck MUCH quieter. Don't forget to check the clamps after 50-100 miles. The vibration made my clamps come loose even though I thought i had gotten tight. Now just add a small tip to finish the look!

-

ECM oddity

So, back before I deployed I used to have to wait for my WTS light to come on. Usually around 5-7 seconds. Started preparing to buy a new ECM for when I got back --- While I was gone I let my co-worker have the keys to my truck, after 2 weeks of being gone he said he killed my brand new Optima red tops that I put in 2 months prior to leaving . Luckily Advanced replaced both of them free of charge and I told him to just keep them on a trickle charger until I got back. The truck went without any kind of battery connected to it for around 5 and a half months. When I got back I put the new batteries in and fired her up and drove away. I've been driving it for about a month now and almost put 1k miles on it since getting back and the WTS delay has completely gone away. It's the first thing to come on as well as the lift pump prime. It hasn't had a single delay.... So far... Did disconnecting my batteries that long essentially "reset" or clear the memory in the ECM causing the delay?? TL;DR -- Had ECM WTS delay, left batteries out of the truck for 5½ months. Now I have no WTS issues for a month now.

-

Lets see who you are!

-

Quadzilla V2 Custom Tunes

Hopefully but probably not. The only thing the changelog says is: "Increased default fuel maps fueling for added fuel for stock vehicles. "

-

Quadzilla V2 Custom Tunes

Just went to check on some downloads and the Adrenaline has a v2.6.1 update released on Wednesday for Standard_fuel if y'all are trying to keep your box up to date @Me78569 Do you happen to have the new timing parameters on the default tune since a few of those parameters have been replaced with * ?

-

Where do I find a genuine HX35W turbo?

I ended up getting a rotomaster rebuilt core for $300 instead of having to buy another turbo for $1100 but holy hell getting that snap ring on sucks