Everything posted by bjytech

-

Master parts diagram or software?

I have a full parts breakdown for 97 truck I'll edit this post with a link once I get home here in the next hour. EDIT: here it is 97 dodge ram parts breakdown

-

Coil Springs

I just did a little searching and found 3 options at napa. Part # NCP 2773271 spring set which is rated at 2640 per spring, Part # NCP 2775415 rated at 935 per spring, and Part # NCP 2775414 rated at 807 per spring. I did some measuring on my truck and according to the wire diameter measuring I have either the 807 or (probably) the 935 rated springs on my truck. My coil spring wire measurement: 0.849 (with some surface rust and dirt on them) 807 coil spring wire measurement: 0.843 935 coil spring wire measurement: 0.843 2640 coil spring wire measurement: 0.937

-

Boost Fooler Really Needed?

Your raptor pump just supplies fuel to the injection pump, The injection pump is where the defueling occurs which is controlled by the ECM, so you would still need a boost fooler.

-

1989 7.3L glow plug issue

I think I know what connector you're talking about, If its what I'm thinking I see it used on older rear end temp sensors and oil temp sensors on semi's, I've replaced many of them before but can't remember the part number. Here's what I'm thinking from what you described: http://www.repairconnector.com/products/GM-Ford-Chrysler-Universal-Stud-Socket-Pigtail-.html

-

Trying to decide on what tires to buy...

My last set of tires were the Cooper discoverer AT/3's and they did well for me in the winter. Quite a few times I drove to or from work when the roads had an inch or more of snow on them and I only put the truck in 4wd for a couple curvy hills just to make me feel better. I got the Nitto terra grapplers now and they seem like a nice tire but I've only had them a couple months so I haven't seen any snow with them yet.

-

Injector Nozzle Swap

Only tip I have is to get them pop tested/adjusted after swapping the nozzles, chanced are the pressures will change even if you use the same size shims.

-

Help, installed NV4500, won't go into gear

Sounds like you have a clutch issue but to be sure are you able to put the trans in any gears with the engine off?

-

scanner...

Cummins insite would show both parameters... but its pricey for just an individual to get.

-

code p1689, no vp needed

Sounds possible to me. I worked on a DT444 (7.3 powerstroke basically) and according to diagnostics it was pointing to a bad IDM (Injector Driver Module), but we knew once you got the thing to start everything worked fine so the IDM had to be fine. After doing some research I found that for the IDM to fire the injectors it requires a minimum of 10.5V and when the starter would crank it drew it down below 9V, Replaced the starter and all has been fine since.

-

Turbo Kits

Rotomaster is an american company that makes their products here but I've never dealt with any of their products personal. That being said personally I would go with a genuine holset kit since I've always got good quality parts from cummins/holset.

-

EGT Probe Locations

You can extend the EGT probe wires but the wires have to be of the right material for it to not skew readings, with a K type thermocouple one wire is nickel and the other wire is chromium.

-

The secret behind a turbo....

read the topic and made my think of this:

-

Front Main Seal

Radiator can stay in place, just have to remove the engine fan, harmonic balancer, and front cover since you're going to check on the KDP as well, although your truck "should" have the updated cover to take care of that issue.

-

Freeze out plugs

The oil drain tube can just be pulled out of the engine block if it gives you to much trouble at the turbo.

-

turbos for dummies... and beyond

Thanks for the links! This is the kind of stuff I enjoy reading and figuring out Saved it all on my computer and dropbox too

-

Brake part Name needed plz

If I understand corectly what you need is shown on the page attached as #2 brake.pdf

-

Under warranty

Tie rods are wear parts, they are going to fail at some point in time its just a matter of when. Regular checks/maintenance are a must for any wear parts, best to check things over good once every month or two and make sure everything is tight and greased, and if you find any parts that are going bad replace them before something like this happens or worse. After getting on my computer and seeing the pictures I see it didn't fail in the way I was thinking when on my phone, I would say thats a defect after seeing the way it broke now.

-

Had a little fun wednesday night...

I pulled in 4low 3rd gear, no shifting in there, at the start I had to let out of it some since it was pretty slick at the start, and I had about 10psi boost coming off the line the last I looked at the gauge. With my current setup I'm at almost 2000 rpm when I start slipping the clutch to get going and build boost, once I get to about 10 psi (it comes on real fast!) I let the clutch all the way out and go for it, this pull I took it to a high of about 3300 rpm, my truck has the 4k GSK in it but I've never gone over about 3300 rpm since I don't have heavier valve springs yet.

-

Had a little fun wednesday night...

We had an inch of rain the night before the pull and down at the start it was pretty slick. I finished right in the thick of it as far as the work stock trucks went, the work stocks didn't have a chance against the 2.5 trucks though

-

Had a little fun wednesday night...

Had some fun at the county fair pulling my truck the other night, never really had a chance at winning anything since they decided to run the work stock and 2.5 trucks together for some reason, but I had fun so thats all that matters! http://youtu.be/5Wabab4oTiU

-

Speedometer bounces up to 35 mph

Really? It seems like just about every 1st gen I've drove/rode in had the same problem, some guys fixed it others just lived with it.

-

Speedometer bounces up to 35 mph

It's probably in the instrument cluster itself, 1st gen trucks are notorious for the speedo going bad in the cluster.

-

Procedure on changing the clutch

I think its easier if you split the trans and transfercase when doing it, If I remember correctly south bend balances the flywheel and pressure plate as an assembly so it will probably have a stripe of paint going across and you want to keep that lined up when you put everything together in the truck. Thats all I can really think of at the moment.

-

LarryB's

Always had a great experience when buying from LarryB.

-

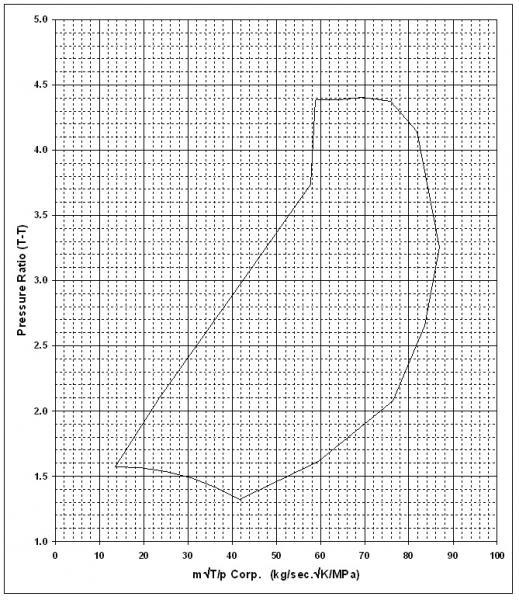

HE351cw map?

Doing some searching I found a compressor map for the HE351cw seems max recomended boost pressure is 49psi, however after about 33psi it's flow rate goes down if I'm reading the map right.