Everything posted by Tractorman

-

Doing a conversion from Auto to standard

If I were going to spend the time and money to do a swap to a manual transmission, I would skip the NV4500 and go for a NV5600 or a G56 six speed (both more heavy duty and more reliable than the NV4500). Both six speeds have a close gear ratio which gives you the proper gear for any driving situation. Plus, you don't have to worry about when the fifth gear nut breaks or falls off (NV4500). - John

-

Elec help - no dash lights, no cruise control, no power to ODB etc…..

As @JAG1mentions, a ground could be the problem. It wouldn't hurt to recheck the wire connections - sometimes a terminal can be pushed back into to the connector and not make contact when the connector is reconnected. Another place that could be a problem is right where the tilt wheel operates. There are multiple wires there where the strands can break internally, but the insulation is still intact. The problem is caused by lots of miles and years of operating the tilt steering wheel which flexes those wires. I had a ground wire break at one of those connection points and caused an airbag light, no HVAC controls, abs warning light, and something else. When I removed the six wire connector for repair, another wire fell off. Likely, it is related to something you did during the your repairs, just re-think it through and you may figure it out. - John

-

New 2022 3500 Dodge Tradesman 6.7 HO Aisin ordered and coming in the fall ???

That's why I have always used 75/140 in the engine. It also is best for oil leaks because it solidifies before reaching the ground - doesn't stain my driveway. Ok..., just kidding. Oh yes they did! They were so reliable and did so much work for you for such a long, long time that you learned to replace them with another one! - John

-

Truck randomly dies. Please help, pulling my hair out, and loosing sleep!

I think I would disregard DAP's suggestion. If it was the case, the engine would not be able to be restarted without bleeding the injector lines since the starter cranks the engine at a much lower speed than idle. Also, anytime it is necessary to bleed the injectors (such as after replacing a VP44), only two or three lines are cracked. Nobody bleeds the remaining lines - they self-bleed while the engine idles. - John

-

VP44 Injection Pump Teardown - How it Works

Thank you guys for posting that you cannot see the pictures. Something strange is going on. When I first posted them, I could see them fine, even after a couple of edits. Just now when I viewed this thread I could not see the pictures. I went to page 6, then back to page 5 and now I see the pictures just fine. I am not sure what is happening, but I hope @Mopar1973Mancan fix it. - John @MikeH, @dripley . and @Great work!, try going to a different page and come back to page 5. Each time I do that, it works for me. - John

-

VP44 Injection Pump Teardown - How it Works

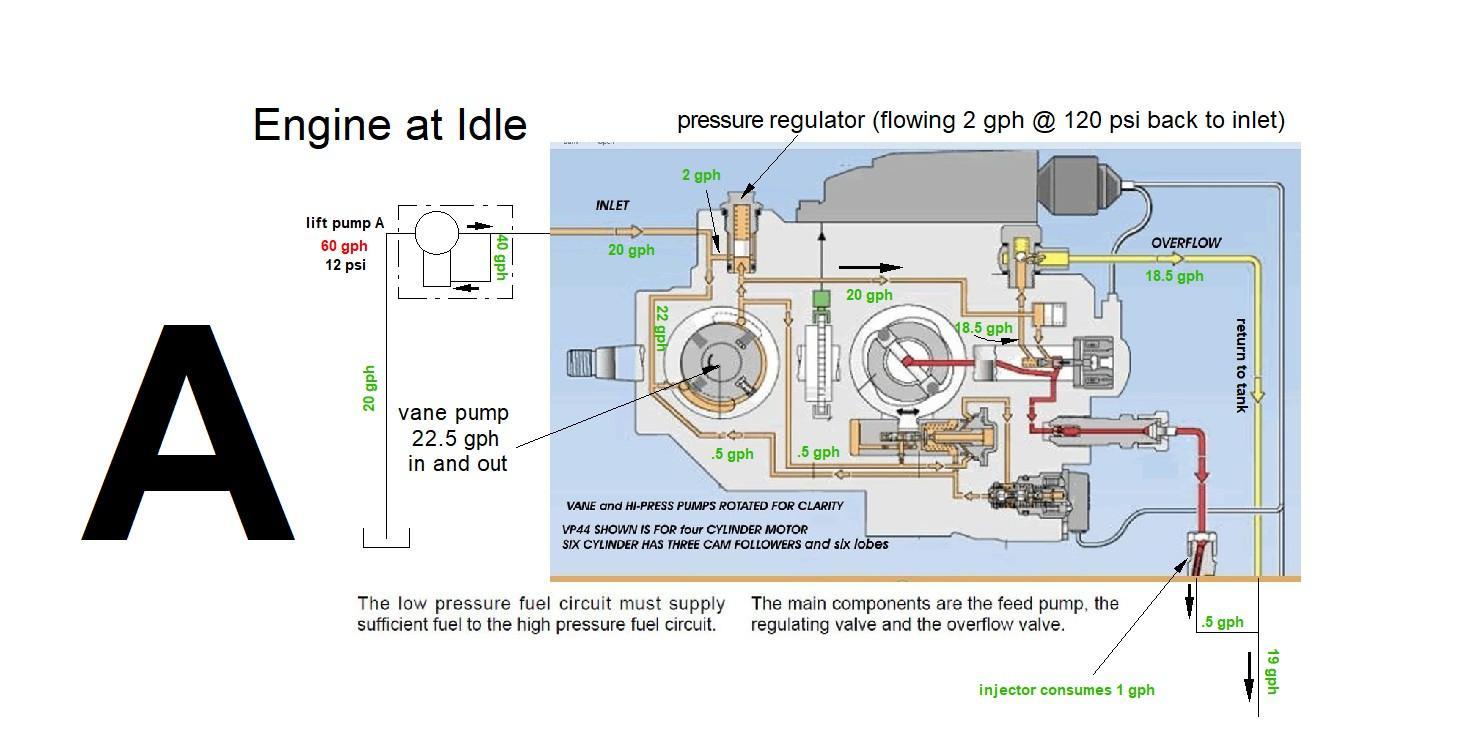

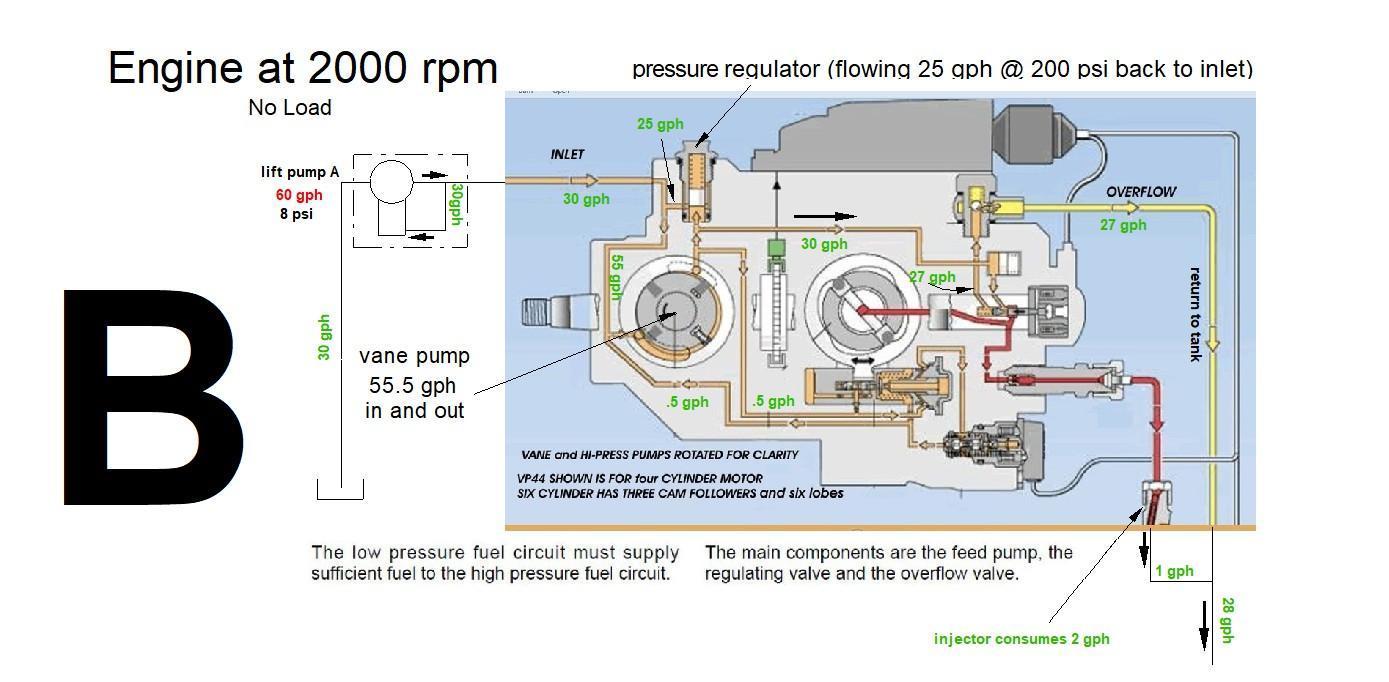

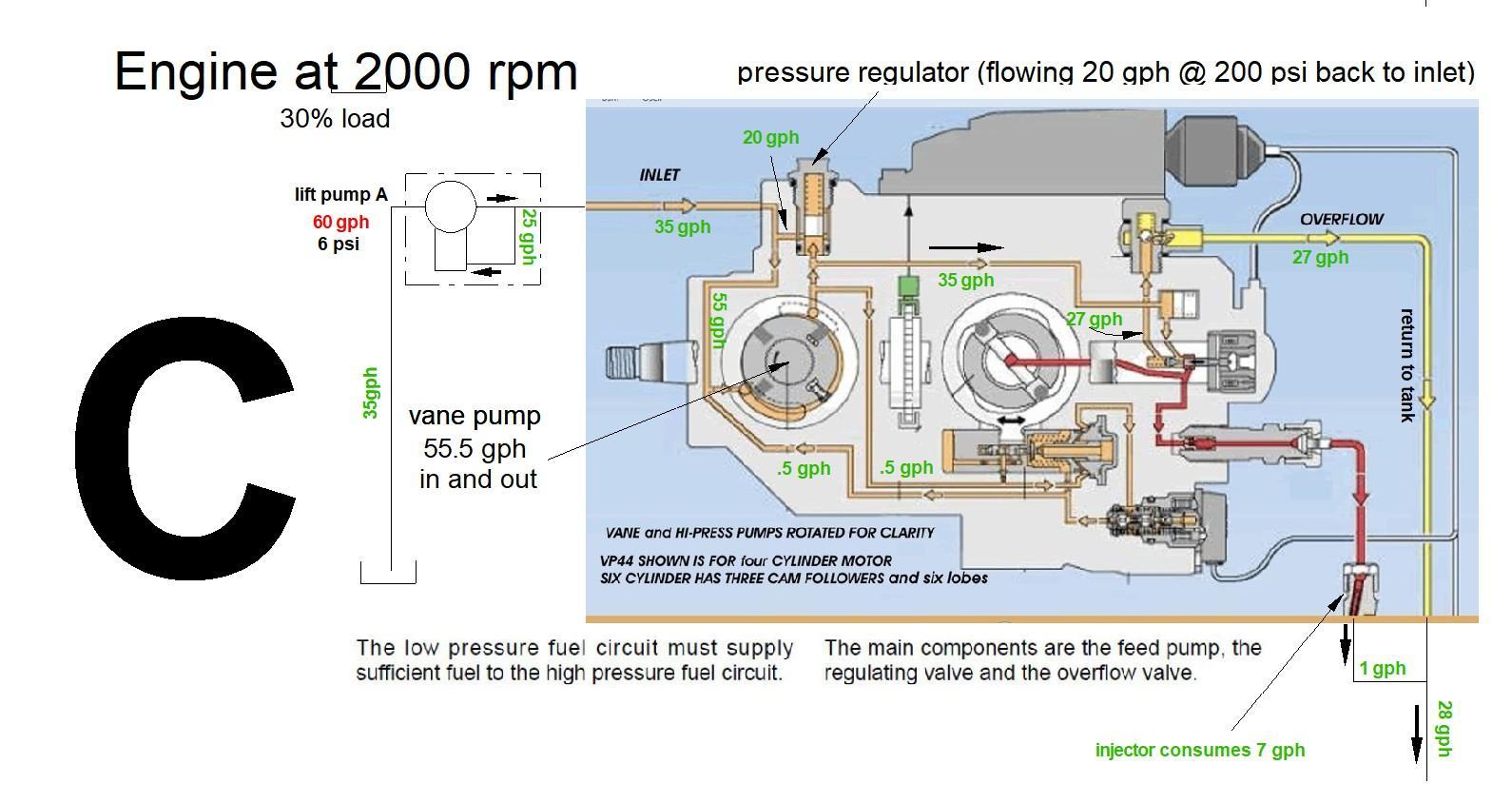

The three diagrams below (A, B, and C) show low pressure fuel flow inside the VP44 injection pump. The purpose of the diagrams is to show what I believe is going on inside the VP44 pump, specifically, the role of the internal vane pump. The flow to the injectors, the overflow valve, and other various internal VP44 components is supplied by the internal vane pump, not the lift pump. The flow rate value that I chose for the internal vane pump is based on my return flow rate shown in one of my previous posts. That test shows that the engine at idle returns 19 gph to the fuel tank. Based on this number, I assigned 22.5 gph for vane pump output in Diagram A. This equals 13 cubic inches of fuel per one vane pump revolution. There are 400 vane pump revolutions per minute when engine is idling at 800 rpm. There are 231 cubic inches in one gallon of fuel. A couple of things worthy of mention: From Jeeper Jimmy a few years ago, The first thing the incoming fuel sees in the VP44 is a vane-type fuel pump (called by Bosch the ‘Internal Fuel Pump’) which raises the pressure to “8 – 22 bar (116-319 PSI) depending on the application and RPM” (direct quote from VP44 Service Manual and Bosch Fuel Injection Pump Manual). From the FSM (2002), A greater quantity of fuel is required for cooling the VP44 than what is necessary for engine operation. Because of this, approximately 70 percent of fuel entering the pump is returned to the fuel tank through the overflow valve and fuel return line. You will find that fuel return flow exceeds 70% of fuel entering the pump in all three diagrams. Circuit A - 95% of fuel is returned Circuit B - 93% of fuel is returned Circuit C - 80% of fuel is returned There may be errors in my calculations - please let me know if something does not make sense. - John

-

Odd find in my 6 speed shift tower

I find that quite unusual as well. I replaced my shift tower with a short shifter, but I didn't like it - mainly because the leverage was lost to return it to center. I re-installed my OEM one a few thousand miles later. The end shaped like a ball had no sign of wear. Neither did the plastic part, both over 350,000 miles. It makes me wonder if there was lack of lubrication in the shift tower on your truck. - John

-

VP44 Injection Pump Teardown - How it Works

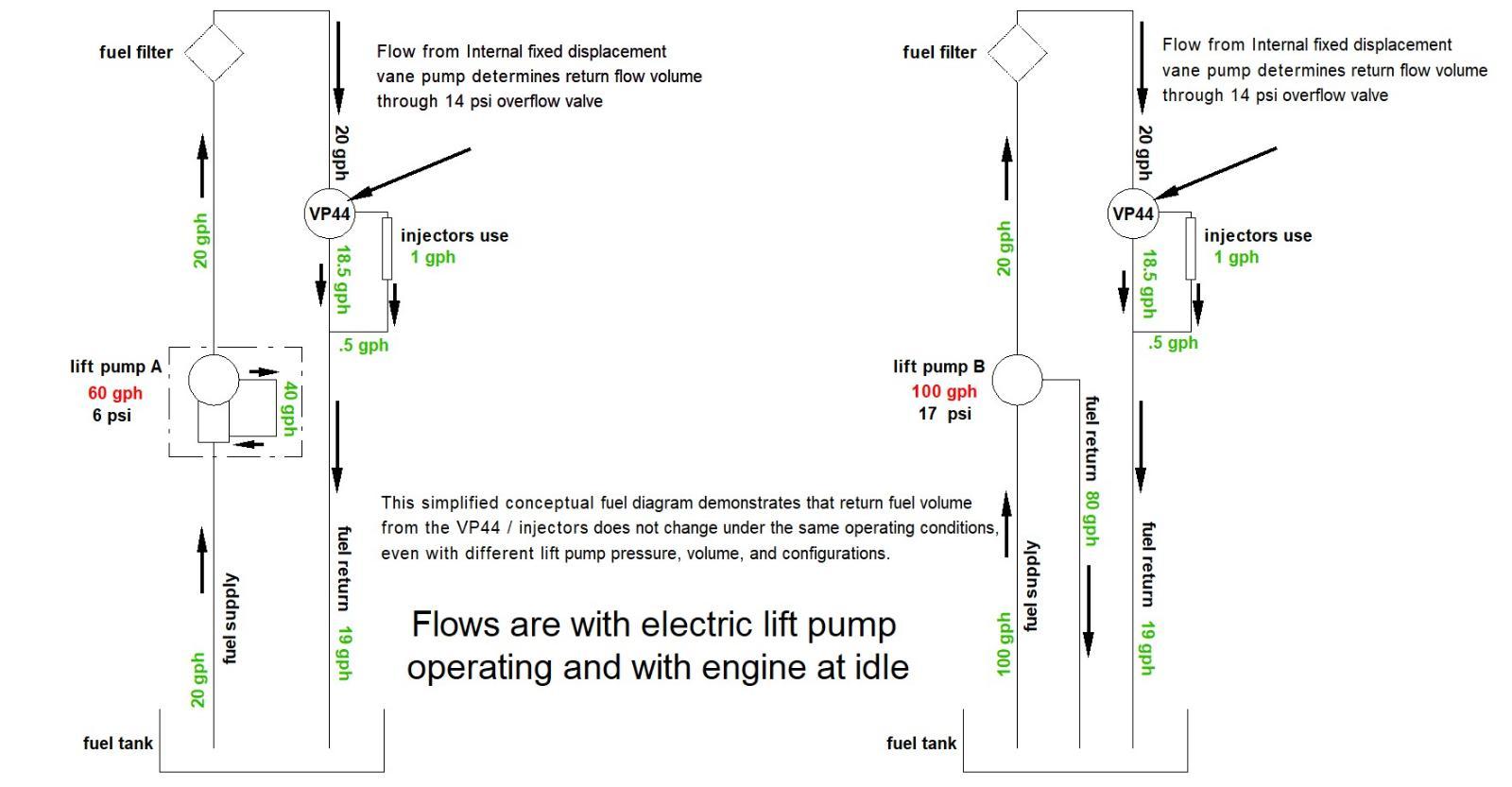

Okay, I got it backwards. The point is, the fuel supply to the VP44 is separate from the fuel return from the VP44 / injectors on your truck.. That is why your fuel temperatures run cooler than most. Are saying that you believe your AirDog 165 lift pump (15 to 17 psi) is providing more return fuel from the VP44 / injectors than a stock lift pump? Because, if you are, then this is where we may have to agree to disagree. The point of my testing is to show that fuel cannot be forced through the fixed displacement vane pump in the VP44, regardless of lift pump pressure or lift pump volume. The lift pump pressure is 12 psi in Test #1 and #2 and 0 psi in Test #3 and 4. The return fuel flow volume did not change regardless of lift pump pressure. The diagram below shows a general concept of how I believe the fuel system works. This diagram only represents my idea of how the VP44 fuel system works. - John

-

VP44 Injection Pump Teardown - How it Works

It could be very possible that "most with a stock lift pump" also have a stock fuel basket which means that hot fuel is being returned right next to the suction in the fuel basket. That alone would make a huge difference in the fuel temperature as the lift pump would be drawing in returned fuel that is much hotter than the rest of the fuel in the tank. If I recall correctly the fuel return line on your truck does not enter the fuel basket. - John

-

VP44 Injection Pump Teardown - How it Works

Just to be clear, I have always believed that there should be a positive pressure at the inlet of the VP44. That is why a lift pump is necessary. The timing piston failed on my original VP44 at 67,000 miles (replaced VP44 at 87,000 mi). The lift pump pressure was always within specifications during that time period. I believe the timing piston failures at that time were due to inferior timing piston and bore material quality because Bosch corrected those issues in their remanufactured VP44 injection pumps without stating to the public that there were issues with them. I appreciate your input. The results of my test show that return flow remains the same regardless of lift pump pressure. - John

-

VP44 Injection Pump Teardown - How it Works

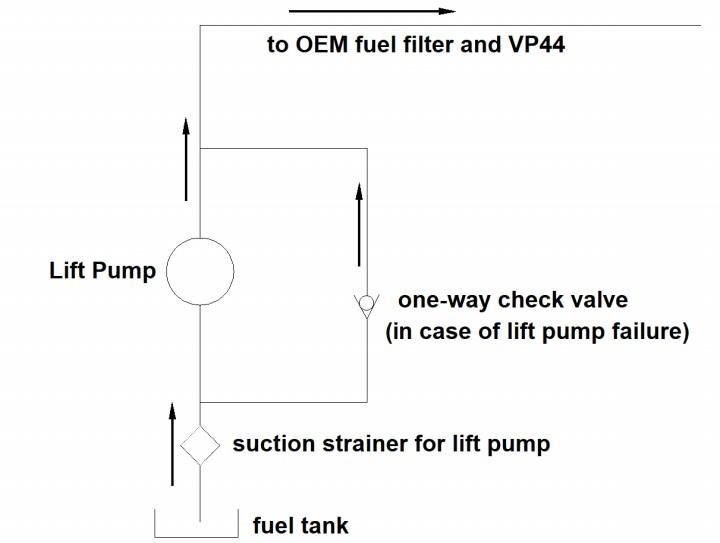

VP44 Injection Pump Fuel Return Flow Test A bit of history – the first VP44 injection pump on my truck failed (code 0216) and was replaced under warranty along with the engine block-mounted lift pump which was also replaced under warranty with an in-tank lift pump in August of 2005 at 87,000 miles. The old block-mounted lift pump was still providing 12 psi at idle and 7 psi at wide open throttle when it was replaced. The new in-tank lift pump provided 6 psi at idle and 3 psi at wide open throttle. I ran that lift pump for 164,000 miles. In April of 2016 at 251,000 miles on the truck, I removed the in-tank lift pump and installed a used FASS DRP-02 frame mounted lift pump. The in-tank lift pump was still working fine – I just wanted the lift pump to be easily accessible if it failed on a road trip. The FASS lift pump provides 12 psi at idle and 6 psi at wide open throttle. Currently, there is approximately 106,000 miles logged on the used FASS DRP-02 lift pump. The current replaced VP44 has logged just under 270,000 miles. As many of you probably know by now, I am a firm believer that the only job for the lift pump is to flow enough fuel to provide a positive pressure at the inlet of the VP44 injection pump under any operating condition. And because I believe this to be true, I have never been concerned about lift pump fuel pressure being low – example: 3 psi at wide open throttle. By design I believe the OEM lift pump produces more flow than the VP44 injection pump and injectors will ever consume under any operating condition which means that there will always be a positive pressure at the inlet of the VP44 injection pump. It is also my understanding that when fuel enters the VP44 injection pump - that fuel flows directly into the inlet of the internal vane pump inside the VP44 injection pump. From this point forward it is the internal vane pump that determines the flow and the maximum operating pressure to provide fuel flow for charging the fill chamber for high pressure injection, fuel flow for hydraulic operation of the timing piston, and fuel flow over the 14 psi overflow valve that returns fuel back to fuel tank for cooling the injection pump. The tests. I have performed several fuel return flow tests from the VP44 fuel injection pump. The purpose for the tests is to show that the volume of fuel returning to the tank (from the VP44 and injectors) does not change whether the lift pump is operating or not operating. To demonstrate this I made one small modification (which will be a permanent modification on my truck) to the supply fuel line. I added a fuel line with a one-way check valve in parallel which bypasses the frame-mounted lift pump. The added fuel line and one-way check valve will allow for free flow of fuel around the lift pump should a lift pump failure occur. During normal lift pump operation the one-way check valve will remain closed. The photo below shows the fuel supply diagram for my truck. For the tests I used a one-gallon oil jug with volume markings at one-quart intervals. I used a helper and started the clock on the 1 quart mark on the jug and stopped the clock on the 3 quart mark on the jug. The total volume returned for each test was .5 gallons of fuel. My truck is a 2002 2500 with a NV5600 transmission. The fuel lines are stock diameter, the fuel filter is the OEM filter inside the filter housing mounted on the engine, and the lift pump is a used frame mounted FASS DRP-02 that probably flows somewhere around 65 GPH. I performed the tests as follows: Test #1: engine at idle, fuel transfer pump operating - .5 gallons pumped in 92 seconds Test #2: engine at idle, fuel transfer pump operating - .5 gallons pumped in 94 seconds Average fuel pumped is .5 gallons in 93 seconds = .3225 gpm rounded to .32 gpm or 19.35 gph Test #3: engine at idle, fuel transfer pump disabled - .5 gallons pumped in 93 seconds Test #4: engine at idle, fuel transfer pump disabled - .5 gallons pumped in 95 seconds Average fuel pumped is .5 gallons in 94 seconds = .3191 gpm rounded to .32 gpm or 19.35 gph Test #5: engine at 2000 rpm, fuel transfer pump disabled - .5 gallons pumped in 64 seconds Fuel pumped is .5 gallons in 64 seconds = .47 gpm or 28.1 gph The averaged test results from Test #1 and #2 (lift pump operating) clearly show that there is no significant volume change when compared to the averaged test results from Test #3 and #4 (lift pump disabled). My conclusion is that lift pump pressure is not relevant to fuel returning from the VP44 injection pump and injectors. The result of Test #5 clearly shows that return flow volume increases with engine rpm, even with lift pump not operating. I performed one other test. Since I am convinced that it is the internal vane pump that does all of the work, I disabled the lift pump and drove my truck to town and back – a 25 mile round trip. I accelerated and held 30 psi boost several times. I restarted the truck several times while running errands. The engine never stumbled and continued to deliver the power it always does. I am not diminishing the importance of the lift pump function, but I will now worry less should I have a lift pump failure while on a trip. I will just keep driving until I get to a convenient place to replace the pump. My overall conclusion is that requiring lift pump pressure to always be above 14 psi or the VP44 injection pump will be sacrificed is now a busted myth. There, I have said it. Of course, each person is entitled to draw his / her own conclusion. One last note…, I know that the VP44 on my truck can fail at any time, but it has already provided a long life, even operating under the parameters of RV275 hp injectors and a Smarty tuner with fuel duration set at 5. I know this will be hard to believe for some, but this VP44 has never seen any lift pump pressure higher than 12 psi, and that 12 psi is only at idle – most of the time it is operating at a far less pressure. The following photos show the volume of fuel returning to tank under specific conditions: - John

-

Uh Oh...wrong oil!

@dripley, I can't believe these guys talk to you like that. I wouldn't do that. I would think it would ruffle your feathers. - John

-

VP44 1998.5 Eyes Burning, Bad Mileage Help

If I was experiencing fumes getting into the cab to the point of making my eyes burn, I would be looking for a an exhaust leak in the engine compartment. A cracked exhaust manifold or leaking exhaust manifold gaskets could cause this. The air intake for the cab ventilation is in the cowling just behind the hood. A cracked in the exhaust manifold can close up as the the engine warms. If the crack is large enough, the turbo could be losing drive pressure, which could account for low engine power. Another source for fumes inside the cab could be engine oil leaking on the exhaust manifold while shut down, then burning off for awhile after the engine is started and the truck is driven. - John

-

front ball joint time

You make a good point here. Portland, Oregon set an all-time high temperature today - 115° - and not even in July or August. The 115° recording was with air at a dewpoint of 51° and 12% relative humidity. So, yes, very hot, but sweat would readily evaporate and cool you. Good example with your drawing. - John

-

Daniel Stern Lighting Sport Headlight Harness

So your truck originally came with a two headlight system and now you have the sport four headlight system? So your returned to you sport four headlight system? Or, your two headlight system? I think you are saying that you tried Daniel Stern's relay harness and this is causing problem with your sport headlight system. If this is so, I would start diagnosing by making sure that the sport headlight system is wired correctly without Daniel Stern's relay harness. That would be: The two outer lights - 9007 bulb (low and high beam filament) both get used. The two inner lights - 9004 bulb (low and high beam filament) high beam only gets used. When low beam circuit is activated, the 9007 low beam filaments are switched on. The 9004 low beam filaments remain off. All high beams remain off. When high beam circuit is activated, the 9007 and 9004 high beam are switched on. All low beams are switched off. Things you may already know: There are separate fuses for left and right headlights. They should be in the power distribution panel. The fuses power the headlight bulbs directly. Wiring from the bulbs (low beam and high beam) goes to the headlight switch and dimmer switch and then to ground. The switches operate in the grounded side of the circuit. I have the sport headlights on my truck and I built my own relay circuit. The system has worked well for years. - John

-

Head Leak

Save yourself some diagnostic time. Pressure check for a coolant leak with a cooling system pressure tester. Perform the test on a cold engine. You will find the exact leak location quickly. - John

-

WHERE TO DRILL A CC/SB 4WD 2500 2001 FUEL TANK FOR A SUMP? WHAT BRAND?

Napa 2790 is the one I purchased. - John

-

Turbo Help

I think you are correct. I think it will perform much better at the higher rpm's. - John

-

Turbo Help

What are the engine rpm's and which gear are you in when you see the 1350°? What are the engine rpm's and which gear are you in when you see the 1300°? What are the engine rpm's and which gear are you in when you see the 1200°? Is your transmission a 5 speed or a six speed? Is the gear vendor in direct drive or overdrive for the above condtions? - John

-

2006 Dodge Adventure!

I had read somewhere some time ago that Dodge did this (not Cummins) for NOX control to come closer to meeting the 2007 emission mandate. I wish I could remember the source. It makes sense to me - a clever inexpensive way to carry over some exhaust gases into the the next intake stroke to reduce NOX emissions without adding on external parts. - John

-

2006 Dodge Adventure!

I believe that the exhaust valve clearance has also changed for that year - from .020 inches to .026 inches for holding back some on the exhaust gases in the cylinder (internal EGR). - John

-

WT mod completed

Mostly depends on the condition of both batteries. - John

-

WHERE TO DRILL A CC/SB 4WD 2500 2001 FUEL TANK FOR A SUMP? WHAT BRAND?

I am glad you edited your post because I was baffled. - John

-

2007 3500 Okay Deal?

I am not an automatic transmission guy. I like six gears that are selectable by me when I say so. But, if I had to buy a newer truck with an automatic transmission, it would NOT be a 4 speed automatic. I agree with @NIsaacs- get a newer truck with a 6 speed auto transmission with an integrated exhaust brake. It would make you wonder why you lived with a 4 speed automatic for so long. I think you would be able to find undeleted newer trucks if that is a concern. - John

-

Vp44 psg removal

@Finlandese and @wil440, thank you for bringing this information to this forum. We here is the USA tend to get tunnel vision and we don't think about the taxes and fees that are imposed on items shipped to your countries. @Finlandese, let us know in a few months how the fix for your truck is doing. - John