Everything posted by IBMobile

-

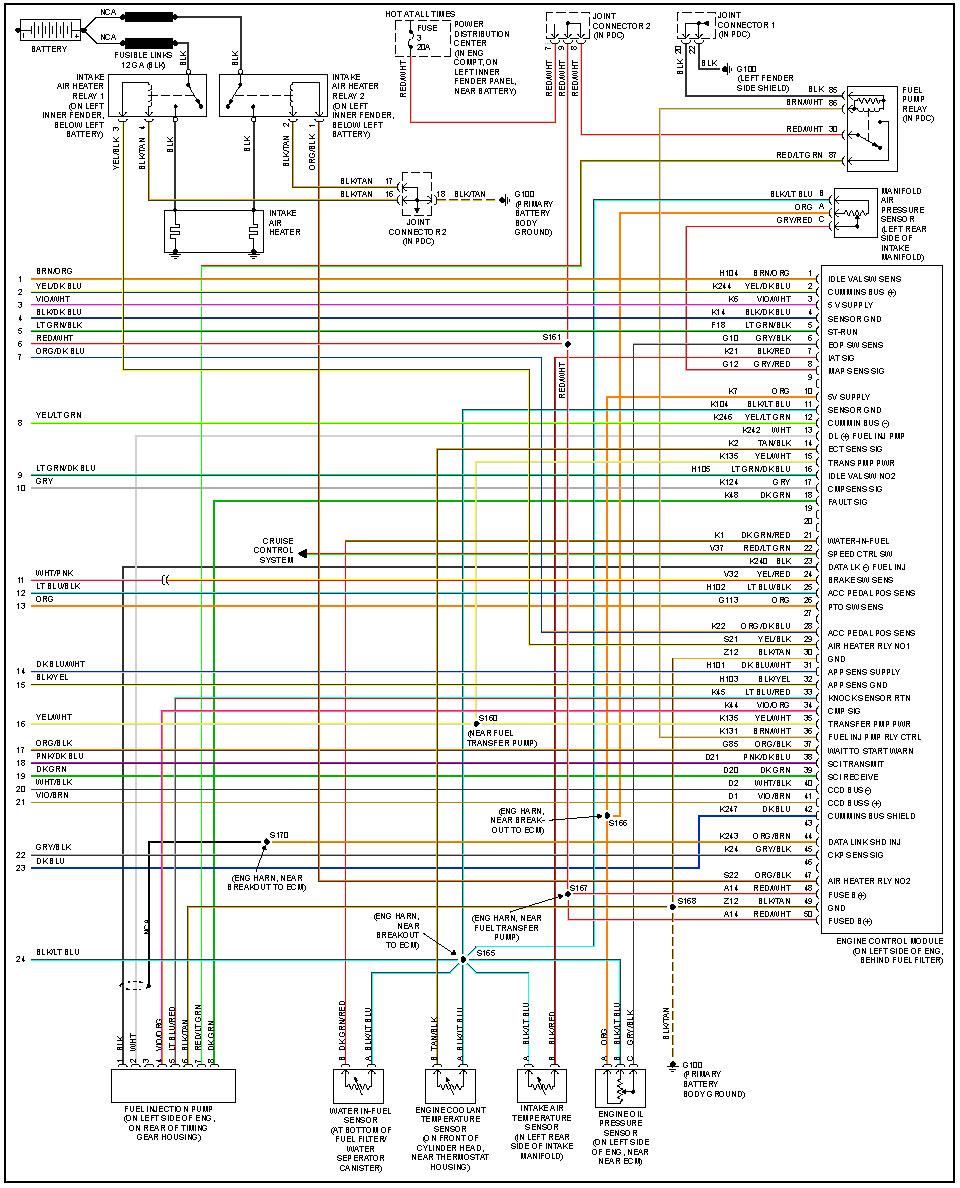

47re

Here's the build sheet and I upgraded the torque convertor to a Goerend 15SS Air temp 91°F Transmission fluid temp 165°-190°F Line pressure, transmission in drive : no throttle stopped 85 PSI light throttle 2ed gear 105 PSI light throttle 3ed gear 110 PSI light throttle 4th gear 120 PSI @ 2200 RPM W/O throttle 1-2 shift 180 PSI @ 2800 RPM W/O throttle 2-3 shift 175 PSI @ 3100 RPM W/O throttle 3-4 shift 150 PSI W/O throttle 4-3 shift 150 PSI 100% throttle 4th gear TCC locked @ 70 MPH 160 PSI 0% throttle 3ed or 4th gear TCC locked down hill slowing 100PSI reverse gear stall test 330 PSI This transmission is putting power down that was wasted with a stock build. I now have the power to the tires to brake them loose or tow my 5er with the boat behind it up an 8 mile 6% grade at 65 MPH with throttle to spare. Thanks Jon.

-

advice on rv or 5th wheel

Get those headache tablets ready.

-

Real head banger, built ats transmission

The OD/TCC solenoids come with all the internal wiring needed.

-

advice on rv or 5th wheel

We need pics of the 5er and hitch.

-

Morning Pic For Today...........Post A Pic around your place.....

- Morning Pic For Today...........Post A Pic around your place.....

- p0108 code

- Speedometer jumping

@Mopar1973Man had an ABS problem. He changed sensors and wheel bearings with no luck. He found the left front wheel tone ring bad/loose.- advice on rv or 5th wheel

Is that £ or $. What makes it "Euro truck towable"?- Mechman alternator

Have you seen this?- 47RE Transmission Temperature Port?

Case in point, When the torque convertor lock up failed in my transmission I noticed the temperature elevated from a cruising normal of 160°-170°F to 190°F and when going up long 6% grades, 5-8 miles long, the temperature would rapidly increase from 190°F to 250°F. After stopping half way up a grade and running the engine with the transmission in neutral the temperature would keep increasing, sometimes to over 280°F before it would start to cool. It would take up to 20 minutes to cool to 190°F. If the temperature probe was in the oil pan I would have never seen that rapid temperature increase due to cooling from the heat exchangers and temperature dilution when mixed with the cooler fluid in the pan. There could have been a good chance of the transmission being cooked before the temperature sensor in the transducer saw the overheat problem and turned the warning light on in the instrument cluster. NOTE: The temperature sensor is in a part of the valve body, just before the governor solenoid, and sees very little fluid flow.- 47RE Transmission Temperature Port?

- Can't sleep bad ideas in my head

Take the money you would dump into this project and invest it. When you retire you will be able to buy one of the new electric trucks, because diesels will be banned by then, and pay cash.- Engine Coolant Temperature Mismatch

- Second gen long gun safe storage

Can you have something fabricated that would bolt under the back seat? Say 28gauge sheet metal with a hinged top, line it with felt and add hold down Velcro straps to keep the guns in place. Incorporate the lock style of your choice.- Bleeding power steering then "pop"?

Test the power brakes. Is there still assist for power brakes from the hydroboost? If good then pump is OK and problem may be in steering box.- 2019 clean air act

In 1977 I was driving a 1968 Camaro home to fix a leaking head gasket with steam coming out of the pipe. About a half mile from home, where I was going to pull the heads, I get pulled over by the CHP. He said I was putting out excessive smoke. After 10 minutes of telling him the difference I convinced him it was steam and not smoke. Cops only know, like the rest of use, what they've been taught. Who said she was going to be elected.- 47re

Before starting any modifications to increase line pressure let's first see if what was discussed on TDR has any merit. My torque convertor lock up clutch went bad and I sent it to @Dynamic for a tear down and rebuild. Since I use my lock up switch all the time it would be very informative to hear what he thought of why the lock up clutch failed. Slowing is when there would be low line pressure and the best chance for slippage. One would think that if line pressure is low enough for torque convertor clutch slippage then shouldn't the other clutches and bands also experience some degree of slippage?- Lock up switch

I'm glad it was easy for you to do and it worked first off. I like where you put that toggle switch and "system on" light. I get the most use out of the lock up when going down hills in 3ed but now that Dynamic has reworked my valve body I'll be using it in 2ed too. That switch is about the same size I used for the grid heater control.- Which Torque Convertor To Get

The flex plate that @Dynamic includes in his "Stage 2" build showed up in the mail yesterday. It feels like it weighs all most twice a much as the stock flex plate on the right. I installed it this afternoon and tighten the bolts to 105 ft.-lbs.. The transmission should be at my friend's shop tomorrow afternoon and installed, hopefully, by tomorrow night.- On board air

I installed a York compressor with a tank setup in a 2004 Jeep Wrangler 4.0L back in 2006. He was getting this Jeep ready for rock climbing and playing in the desert and want to be able to air up his tires as needed. It worked all right for that. Volvo also used York compressors through 1984, In my work van I have a 5HP/30gal compressor which I hardly ever use. I mostly use battery powered tools now.- 3 way lockup switch

What @Gregturley said is how it works. Don't push any button or switch and it's the factory setting.- Bad PCM now?

In this article is a section on testing the AC clutch- Questions replacing battery cables

You can go to a battery supply shop. The kind that sell just car, truck, RV and stand by batteries. They have all the cable ends and cable you need. The will either sell you the material to make your own or make it up for you. The cable ends that you are showing are about 60¢ each at the shop I go to. Try Pacific Power Batteries. There is Batteries Plus Blubs, they do repairs on small things and may have the supplies. .The solder to use on the cables is 60/40 tin-led (SN-PB) rosin core type. I use a butane micro torch to heat and solder the cables and terminals together. Before I solder the terminals on to the cable I orientate them as how they will be when fitted so there is no twist in the cable. If you're going to use heat shrink slide it on the cable first and at least 6'' from the end before soldering. Do the soldering like @01cummins4everposted and you'll be golden.- Headlights

Right now, about 20 miles from here, there are 8 Ram 1500 in the wreaking yard but it's rare to find a 2500/3500 there. A lot of the parts from the 1500 will work on the 2500/3500 models. You can always find a nice after market trans cooler or part you can use off of a Ford, Chevy, or Volvo that you can adapt for something. https://www.lkqpickyourpart.com/locations/LKQ_Pick_Your_Part_-_Oceanside-286/recents/ - Morning Pic For Today...........Post A Pic around your place.....