Everything posted by Haggar

-

What I have done/found on Ole Blue today

-

Front end popping noise

To find your sloppyness, you have to get someone to wiggle the steering wheel for you. You will begin checking in this order: 1) Steering shaft to steering box. put your hand on the shaft. watch the person turning the wheel. the shaft should react EXACTLY like the input. (the two things you looking for here is/are the rag joint (about midway to the steering box under the hood. and the input to the steering box. The input you just have to watch and make sure. the rag joint you can use two hands (one above and one below) it should move EXACTLY the same. 2) Steering box output shaft (the shaft the pitman arm connects to.) Have the person audibly tell you which way they are steering. Make sure you note when they say going back to left to see if there is a delay in the new directional movement. 3) Pitman arm drag link connection. put your hand around this joint. close your eyes and feel. As the box changes direction do both parts move EXACTLY the same or does one part move a bit before the other? Does the draglink rotate before it begins moving? Our truck are notorious for the steering gearbox to get loose and need tightening. I have personally had the pitman arm draglink connection go bad a couple times..... (there were two different taper lengths used. It could be someone didn't notice and put the wrong combination together and it doesn't tighten properly. Lay under the truck while the person wiggles the steering. Everything should move together and the wheels should try to turn immediately. Watch for the item that doesn't move EXACTLY with the other items. GL HTH Hag

-

Low Fuel Pressure Light and Big Line Kit

Yes, Provide ground to sender threads. I played with large ring connectors and such. Sometimes they work fine, sometimes not (npt threads don't end up in same place all the time etc. I also got away with soldering it to the the brass tee and then screwing the sender into it. Then grounding that wire. sometimes you can find tees and elbows (made for plumbing) that have a tab with a hole (to mount to a wall stud) that would allow you to bolt the ground to the fitting without drilling and tapping. GL HTH Hag

-

No 4hi, only 4lo

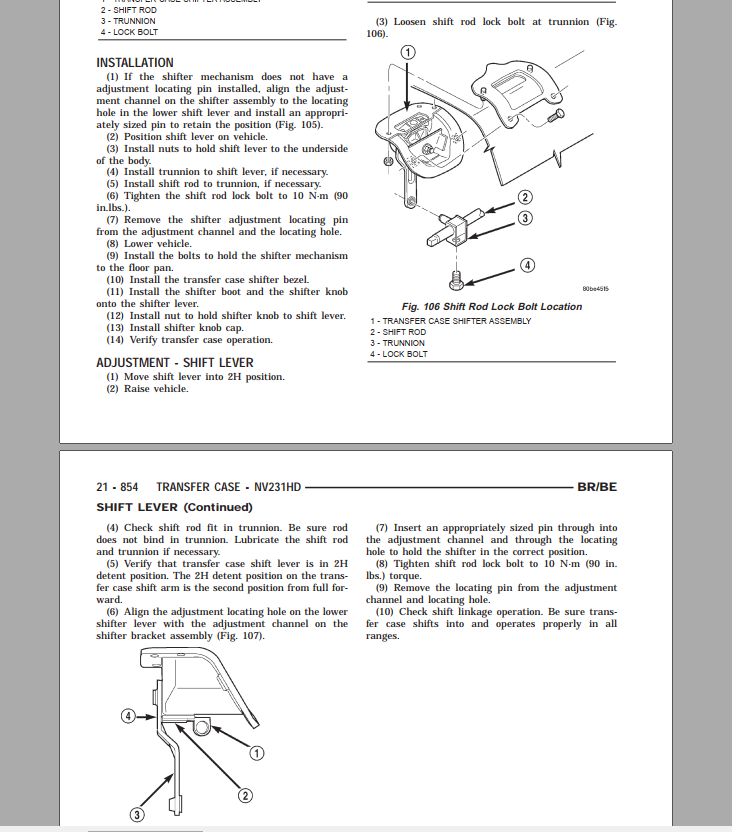

There is no adjustment in the switch. It screws in. It is possible that the bushings in the linkage or like you said bent shift lever. Here is the adjustment procedure. GL HTH Hag

-

VP44 Injection Pump Teardown - How it Works

Guys, remember the outlet check (the 14psi when FULLY OPEN) is not fully closed at zero PSI. It has a bleed through. It is a variable restriction, but not a "check" It will flow with 0.0 psi differential (ok you can;t have flow at zero differential it's in the definition, but think of the smallest differential you can imagine...). Pull yours out and test it. Hag

-

VP44 Injection Pump Teardown - How it Works

W-T I think post running circulation would make a big difference. The stanadyne on the GM 6.5 had a similar issue.. The fuel valve solenoid gets hot. I have a good friend that I have been bouncing this around with. He has been watching some of the European videos where they are going in and replacing the driver chips. (remember I am mechanical so may not be correct on the proper electrical terminology) He said that the drivers seem to be very small and fragile looking. It may be worth some time to improve cooling. Hag

-

Truck Eats Coolant

Pressure test the system while cold. That will tell you if you have a gross leak somewhere. Mine loses coolant only at certain temperatures from the passenger side front headgasket. I never see it wet. It does not leak cold (will hold 16 psi cold for hours) but I can see the dried coolant from that corner. I have to add about a quart a month. HTH Hag

-

No power in reverse

When in reverse trying to back up the weight, does the engine freely spool up or does it try to stall? If the engine rpm increase with no gain in speed, the clutch is slipping or the torque converter is not converting. If you stall you don't have enough torque to perform the maneuver. HTH Hag

-

No 4hi, only 4lo

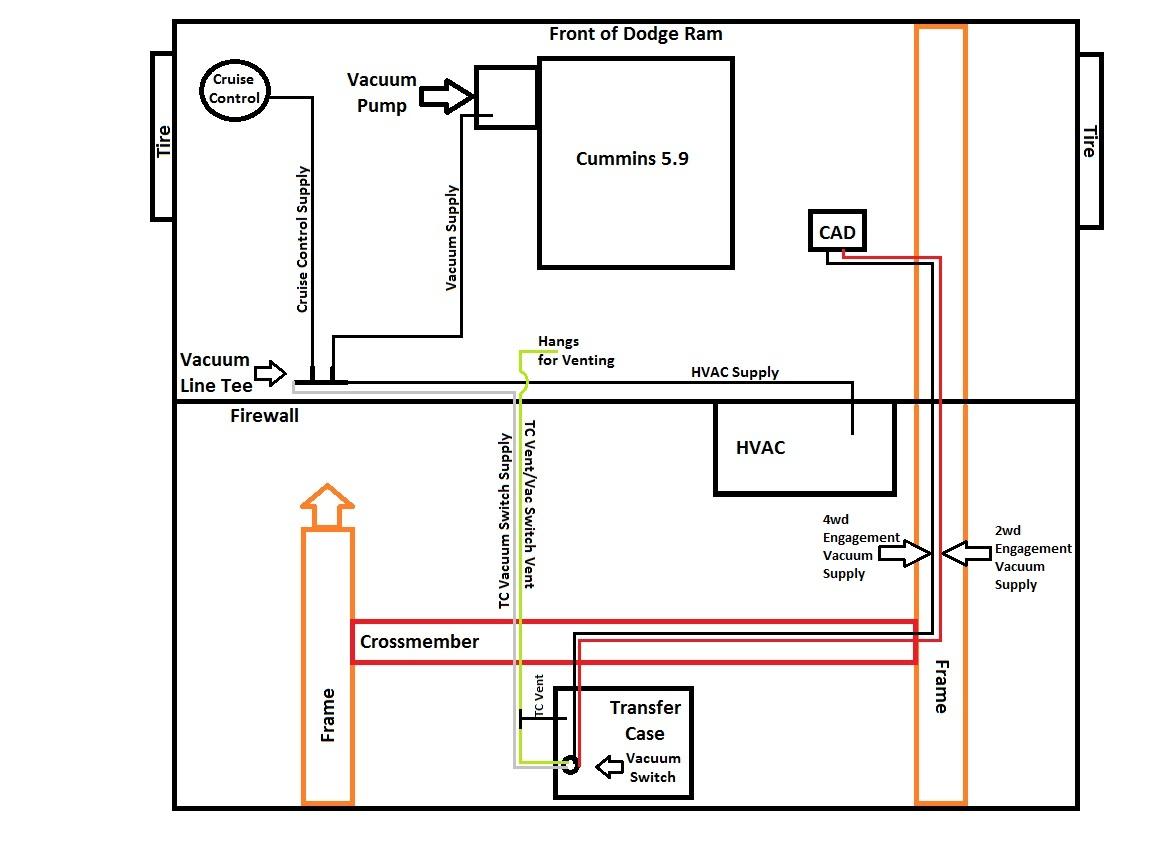

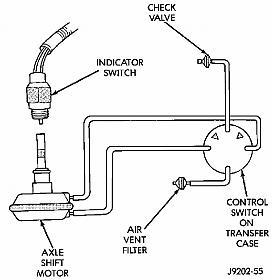

Guy, The switch on the transfer case could be bad. It is where the electrical switch is on a GM, ours is just vacuum. When you select 4 hi or low, vacuum is supplied to the black line to the cad (also called axle shift motor). The red line should have vacuum only in 2wd. I wonder if your valve is bad or something so that the vacuum does not get there in 4 low. You may need to play with it a bit, because it is a detent, if you are not putting the lever in the right spot it may be wonky.

-

Hydroboost leak

PM sent

-

Gen 3 track bar conversion

Do what you can to help the lower control arms be a bit longer. This helps with our fixed caster on the 4wd vehicles. GL Hag

-

TAPPET COVER GASKET REPLACEMENT

The vent line for the 4wd vacuum switch comes up behind the head and ends with a black filter/cap. This was to prevent dirt and debris (and mud dobbers) from plugging the vent line and rendering the cad system useless. That could be what you are looking at. Hag

-

Gen 3 track bar conversion

Good job nailing the center!!! I usually blow that and spend another 3-5 hours trying to finger out how to fix that too! GL Hag

-

99 auto immediately after refreshed injectors stalls when placed in D or R

I love "the nozzles are designed for this..." OK. so they are. they make a proper pattern at a lower pressure. That is a total dodge (pun not intended) to the question asked. How does the injector backward command the pump to respond to the earlier timing of the first fuel flow and the longer open window of the injector time? Hey in the old days you would just adjust the timing of the pump a bit to get it level out. Run out there and adjust your timing on pump.....ooops. can't advance or retard the VP easily. you could with keys..... None of us has really played with it as a serious scientific study. But there is some good data here from people with good engines that have investigated playing with pop pressure. None of it is proven so it is still a theorem. But I would say I have seen some great empirical data that suggests higher pop pressures (to a point: cold start begins to suffer and higher elevation guys noted oddities) smooth idle out. Just my $0.002 Hag

-

99 auto immediately after refreshed injectors stalls when placed in D or R

Joe, Finding a "good" diesel shop is going to take some leg work on your part. The "good" diesel shops work on commercial vehicles, not residential stuff. So what you need to do is familiarize yourself with some commercial vehicle repair shops. (I am not sure how much farming is near you, but shops that work on the BIG tractors 150hp+ would work too) See if there is a Volvo, Freightliner, dealer etc near you. ( it appears that Freighliner of Philadelphia lists levittown as its home) go talk to the mechanics there. They will tell you what shop is good with injectors near by (or not near by...) Do not be in a hurry and be super humble. But with the right questions in the parts/service department you will find the information you want. Let other customers go ahead of you if they know what they want etc. you are asking for information that really won't pay this stores bills. be super flexible and just listen. One of the customers there might listen in and pitch in with who they were happy with. GL HTH Hag

-

Truck shakes at 55-65mph, Grinding/vibration when coming to stop as well.

A couple times on different vehicles I have suspected that the wheel bearing was the issue, but even with it up on the lift I could not "feel" a problem. No movement on the dial indicator nothing. Mentioned this problem to my local parts guy (been in the business YEARS...pretty darn clever) and he said he had run into that also. He suggested loosening the spindle nut, thereby removing the preload, and spinning the wheel. (of course re-torque it if no issues) VOILA!!! the bearing felt like hell. Tighten the spindle nut, felt fine, loosen the spindle nut, felt like hell. Pretty darn amazing. Just my $0.02 HTH Hag

-

Tuning Quadzilla

And yes, the VP can be dead or dying with no P0216 code. 216 is a nice confirmation it's toast, but we know of at least 4 that had severe drive-ability issues and never threw a P0216 code. A couple never threw codes out. HTH Hag

-

Left turn signal working wipers

My '53 Sunbeam had the letter "B" on the the hood release.... Took me awhile to figure out it meant bonnet. lol of course the turn signals were little flags that stuck out from the fenders.... whitworth threads.... plumbing on the outside of the house so it is easy to fix when it freezes, carburetors made by plumbers... and Lucas the prince of darkness.... I understand why the UK loves beer. and once you get in the right frame of mind, it all makes perfect sense! CHeers!! Hag

-

Possible Game Changer for lighting our trucks $211

If were gonna slip on moral pants here, it should go both ways. What is wrong with the coatings that the NHTSA is forcing the OEM to apply to the headlight lenses that they (headlight covers) yellow out so quickly? It has to be a stupid regulation. Do your tail lights yellow that quickly? Do any of your other clear plastic covers yellow that quickly? No they don't. SO somewhere along the way, there is a regulation that these headlight covers get this crazy chemical applied to them. (I am betting it has to do with not making sharp shards, so that a pedestrian is not injured or something like that.) just make my headlight covers out of the same material my reverse lights are made of, and I won't need to add more and more energy to the lighting to see through the fog of the plastic..... Just like the stupid fuel cans.... someone saw a way to prevent as much fuel from evaporating from a can. BUT I now spill more fuel trying to use them..... for me, the greenies lost. I spill significantly more fuel than I ever let evaporate from a fuel can. GL Hag

-

Left turn signal working wipers

Wil, Just make sure you have some of the "tamper proof" torx bits. (they are the torx with the pin hole in the middle) you will need them to take out the multifunction switch. HTH Hag

-

Billet Tappet Cover Selection and Installation

I removed the front timing cover breather. I probably have more blow by than most, so the front of the engine stayed a bit dirtier. The worst was it would collect on the alternator. Don't know why. It just constantly looked like my alternator had an oil leak. so I moved it. routed the new lifter cover vent into the driver's side frame rail. It will never rust out. Hag

-

Billet Tappet Cover Selection and Installation

I installed an earlier Cummins tappet cover with the vent. I did it because I had a broken gasket and needed to be in there anyway. It takes some time to do. The stock lift pump bracket must be modified. (this bracket also covers the p-pump version mechanical fuel pump hole) So gaskets need to be made etc. Personally I like it. But it is not just a quick change. I also used the earlier version washers to hold it in place. I think I would have been better served using the newer washers. (our later washers are much thinner.) I ended up having to go back and re-tighten the cover bolts. I added thread locker so I didn't have to go back a second time. Not sure why I had to re-tighten them.... but they worked loose. HTH Hag

-

Intercooler Bypass

just remember to get all the cardboard out.... I would put a half cardboard on a chevy I had. It slipped perfectly between the condenser and the radiator.... I guess it fell in a bit far for me to see and I forgot to pull it. nearing summer I was running hot and infrared gun showed only half of my radiator was cool, the other hot. (one would think this woulda sparked some brain activity..... but nooooo) So bad radiator.... I was so mad when I got the old radiator out..... Don't pull a Haggar. lol Hag

-

Newest HO Alternator Options

I think you should try to isolate the winching battery from the alternator. When you start winching, it will pull amps from where it can get them. If for some stupid reason (or the batteries are too dead) it will start pulling directly from the alternator. (I have my dump trailer set up with a relay that disconnects the truck aux power that charges the battery. when I power the dump up, it disconnects the truck aux) The best set up I did on most of my 4xs was add a battery with diode isolation. It would charge the extra battery but would not creep back and directly load the truck battery or alternator. Since we start with two batteries.... it is gonna be tougher, though you might be able to do the relay (it would be a starter solenoid for that many amps) to separate the battery from the system. Good Luck Hag

-

pulling to left while accelerating

Don, you were the fellow that got shafted with a toe and go.... Like trouble said look for looseness in the rear suspension. because they did a toe and go, they didn't check your thrust angle. If you can repeatably accelerate and see movement that you don't see off throttle or decel, you are getting some rear steering. Don't forget the basics though. Tire size and pressure on the rear. is your rear sway bar doing something wonky....(it should only work in the vertical,but if the knuckles are seized etc. GL Hope you find it! Hag