- Replies 124

- Views 11.7k

- Created

- Last Reply

Top Posters In This Topic

-

Doubletrouble 27 posts

-

JAG1 20 posts

-

Mopar1973Man 16 posts

-

Tractorman 16 posts

Most Popular Posts

-

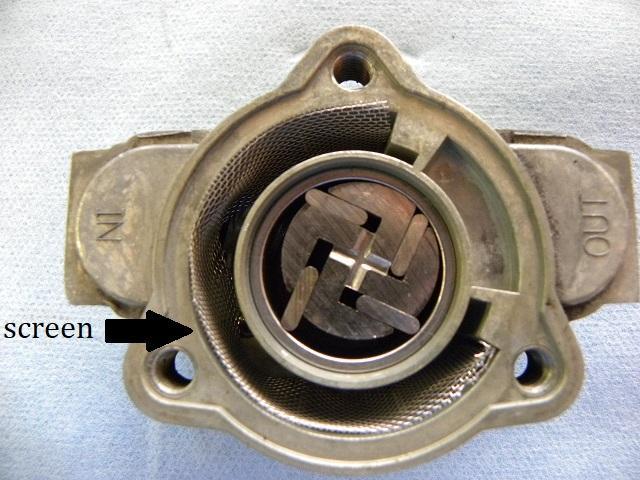

As long as your pressure is reasonable it can't hurt anything and I'd certainly try it. As goopy as the stuff was around my screen (imagine wet coffee grounds, but much finer), it may not "clear it"

-

Since the word “cavitation” has been used a few times in this thread, I thought I would clarify the meaning of “cavitation”, specifically “pump cavitation”. When the suction pressure of a

-

Under Fuel Injection Pump Description, The FSM states, "A greater quantity of fuel is required for cooling the VP44 than what is necessary for engine operation. Because of this, approximately 70 perce

So on my way to work this morning I noticed my pedal was for the most part dead. No acceleration and the engine was "missing" for lack of a better term.

Made it to work, truck idled smooth like any other day but if revved a few times it would begin to miss again.

Had the OBD scanner in the truck so plugged in and saw the P0216 code. That was the only code present.

I know this is the VP death code but before I drop big $$$ on a pump, is there anything else I need to look at? I want to properly diagnose this and not just throw money at it. Can't afford that rout right now.

Thanks in advance......