- Replies 22

- Views 4.7k

- Created

- Last Reply

Top Posters In This Topic

-

Timburrr 8 posts

-

notlimah 4 posts

-

Mopar1973Man 2 posts

-

jlbayes 2 posts

Most Popular Posts

-

1 - If you know you're planning on a turbo upgrade, go with the "in line" exhaust brake. It'd suck to buy a turbo mounted brake and have to buy another in the near future. 2 - I prefer the stain

-

As far as exhaust materials go, this next time I get one it'll be stainless. I went with a standard aluminum diamond eye with my 99 and although it's not rusting, it does have some surface rust I wasn

-

I would plan your exhaust brake around the turbocharger you plan on using. Hate to buy something and it not work later. I am not a fan of 3 piece manifolds. Stainless steel one piece are all I recomme

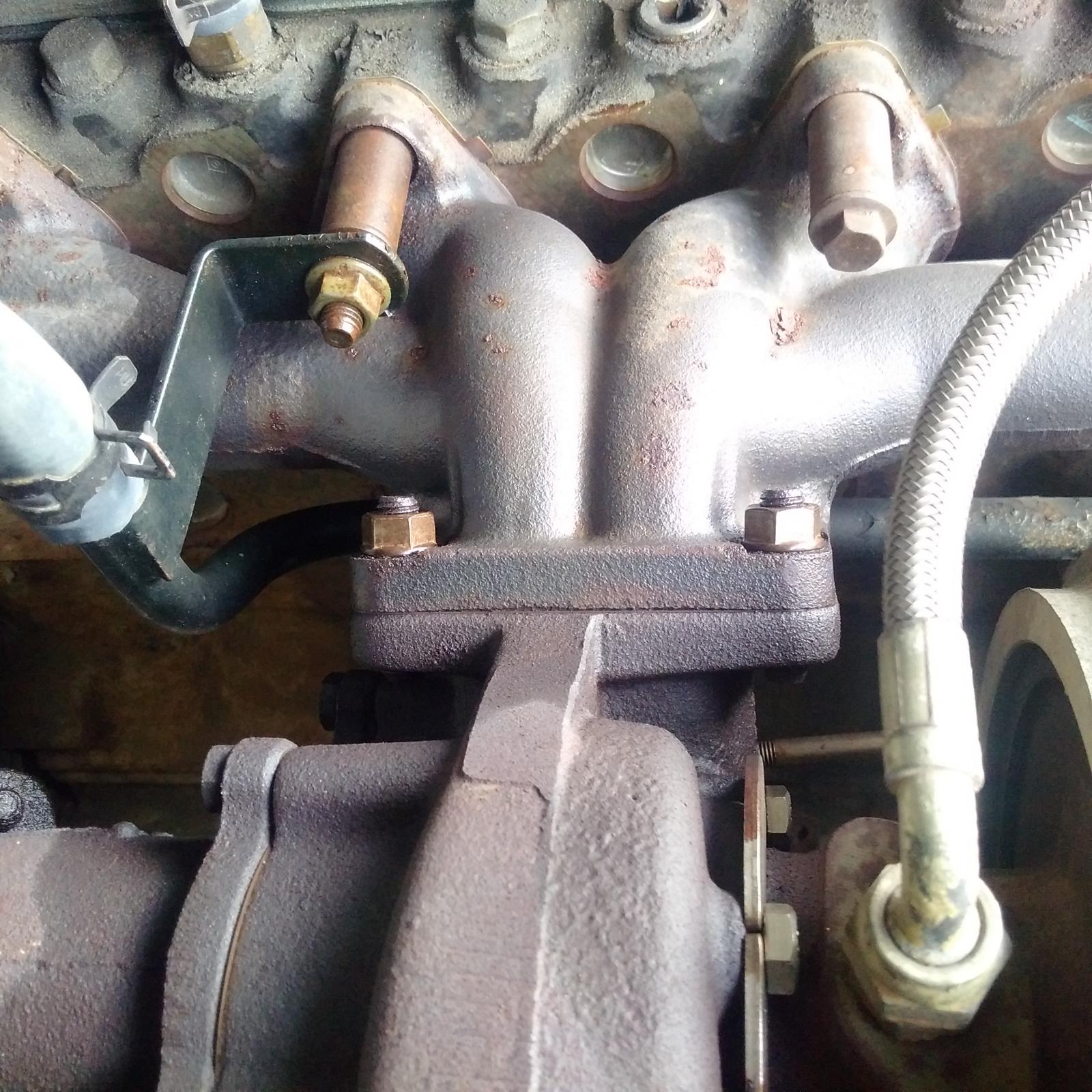

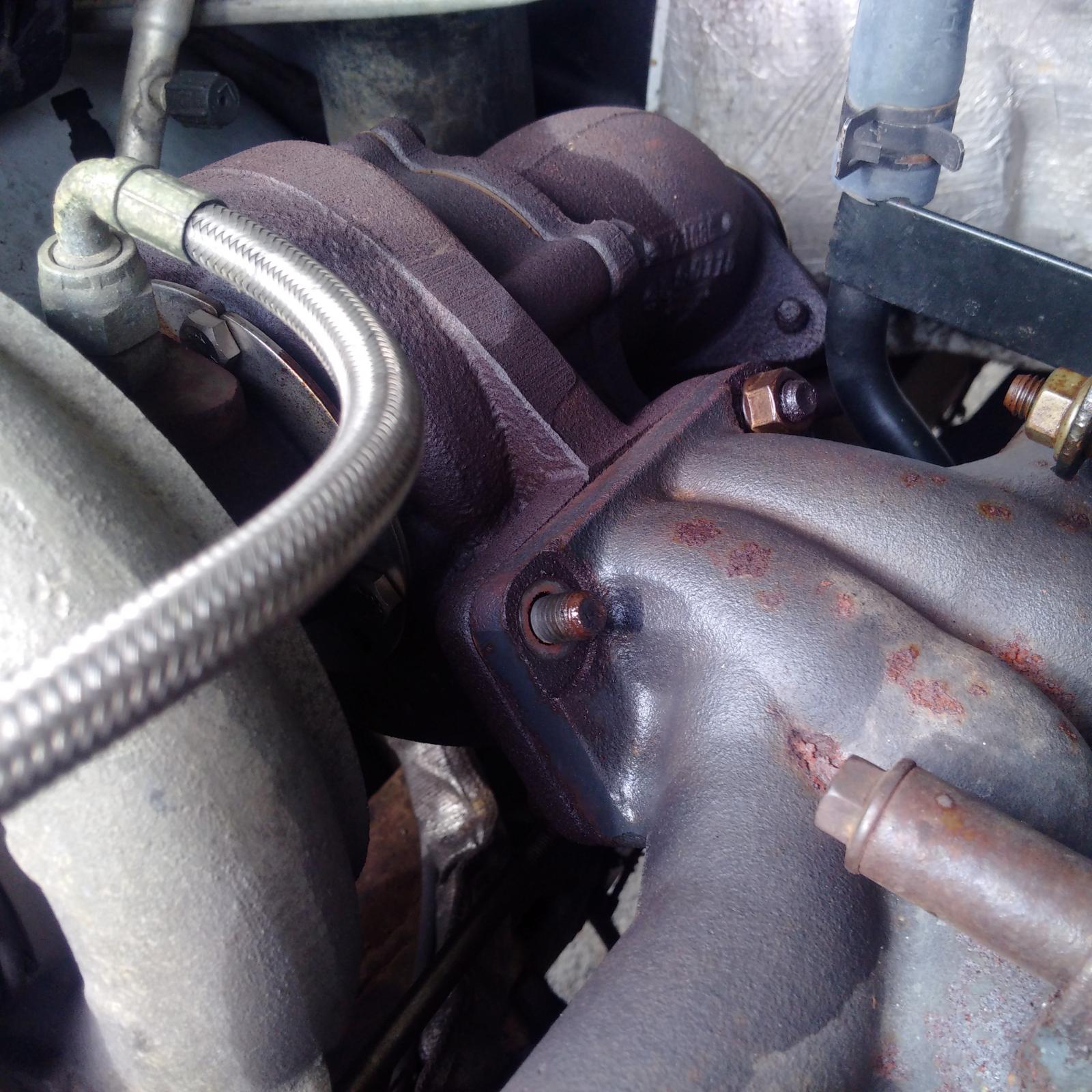

I'd like to hear some thoughts on parts i'm going to be ordering soon. My exhaust manifold is cracked and my muffler has a good rattle and I'd like an exhaust brake for towing and to a lesser extent service brake life. Truck is a 1999 24v 5speed longbox.

1) I would prefer the the turbo mount exhaust brake but I may do a small turbo upgrade in the future which from my reading means I'll need to have the remote mount brake. So i'm thinking the BD remote brake.

2) I'm leaning towards this exhaust manifold. Price seems good and I've heard good things. DAP T3 with EGT probe bung and comes with gaskets and hardware. https://dieselautopower.com/diesel-auto-power-assembled-3-piece-t3-exhaust-manifold-pyro-tapped-with-gaskets-24vt3m/

I don't understand the turbo gasket, whether I need divided or undivided?

3) I want to do a 4" turbo back exhaust with muffler to kill the loud drone when towing a load. I figure long trips with the wife and kids will be better with less noise in the cab. I'm thinking of this one from DAP:

https://dieselautopower.com/1994-2002-dodge-5-9l-cummins-turbo-back-stainless-steel-kit-single-4/

I like the idea of stainless and with the remote exhaust brake being welded to the exhaust I would like to do a stainless for longer life. Thoughts on this? Would it be worth it to pay the [a lot] extra for an MBRB? Sounds like better steel but its a lot more money.

Any thoughts on this would be very appreciated. I plan on, down the road, doing a small turbo upgrade and maybe 50hp injectors. I have a 53 block with 200,000+ miles on it so don't want to go crazy with modifications but wouldn't mind a bit more power.

Thanks so much!