- Replies 16

- Views 18k

- Created

- Last Reply

Top Posters In This Topic

-

Mopar1973Man 4 posts

-

Dieselfuture 3 posts

-

Ben 3 posts

-

Stanley 3 posts

Most Popular Posts

-

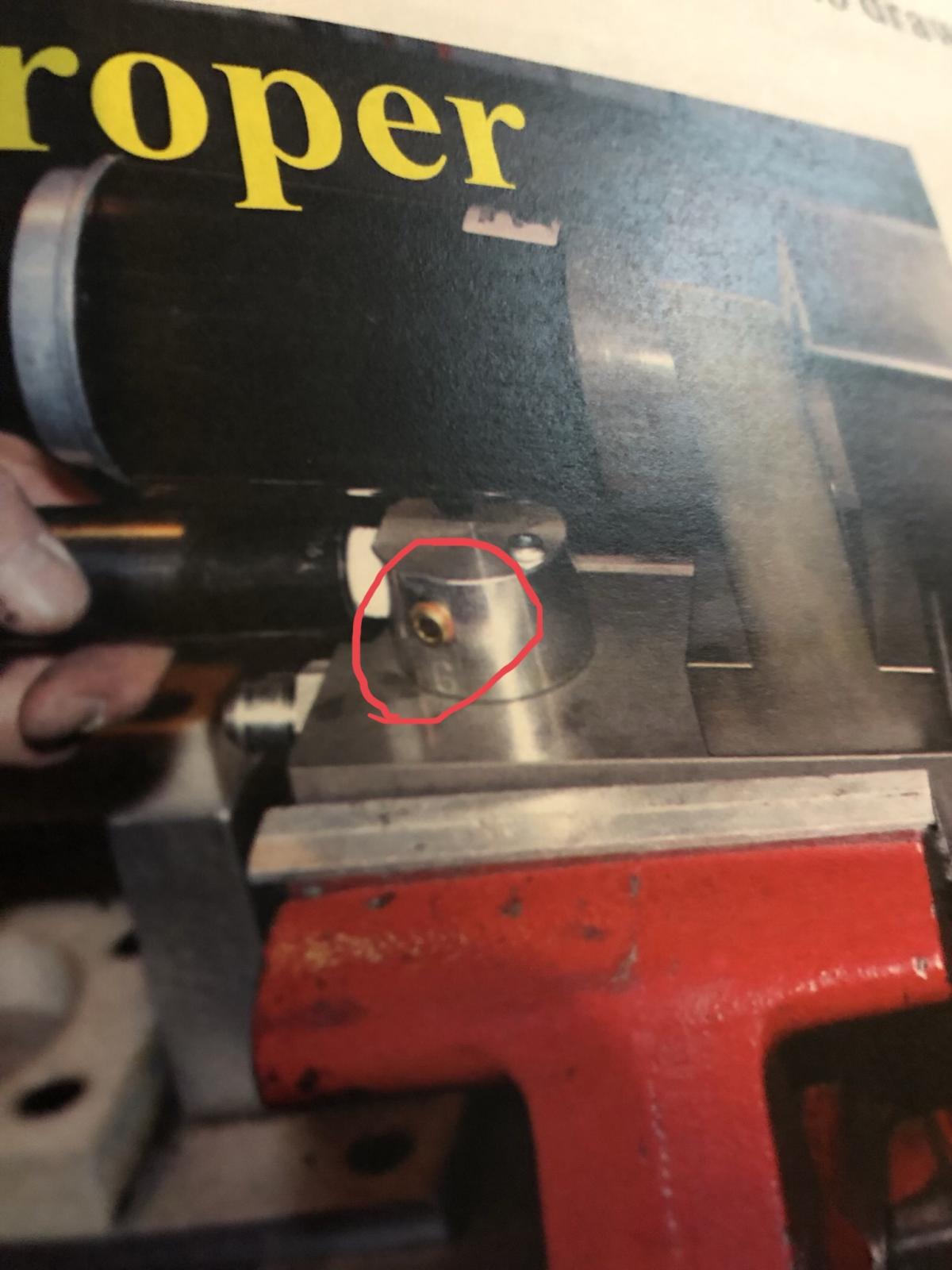

Here is the installed test port. Eta- just installed new spring and ball. I’ll be damned, it worked. 18lbs.

-

The return line fitting on the pump. Remove the fitting and behind it should be a spring and check ball. Now there are a few things to do. The spring needs to be bent in a manner that the tail of the

-

See what happens. Right when feel special, a concrete block falls out of the sky and puts a knob on your noggin.

I have seen it before some where but cant find it anywhere... HA

Short and sweet:

Where can I get a shim or make one to increase my psi on my fass 200 titanium. Heard of guys shimming with washers, but id like to move from a consistent 14-15 psi to 20 psi for my bigger IP...