Everything posted by Mopar1973Man

-

Cutting out surging bucking

The funny part is that the Cummins engine really has very few sensor and things to go wrong... ECM connections... http://mopar.mopar1973man.com/cummins/general/ecm/ecm.htm Inputs Accelerator Pedal Position Sensor (APPS) Volts APPS Idle Validation Switches #1 and #2 Battery voltage Camshaft Position Sensor (CMP) CCD bus (+) circuits CCD bus (-) circuits Crankshaft Position Sensor (CKP) Data link connection for DRB scan tool (FPCM) Fuel Injection Pump Control Module Engine Coolant Temperature (ECT) sensor Ground circuits Intake manifold Air Temperature (IAT) sensor Manifold Air Pressure Sensor (Boost Pressure Sensor) Oil pressure sensor PCM Power Take Off (PTO) Power ground Sensor return Signal ground Water-In-Fuel (WIF) sensor Outputs CCD bus (+) circuits CCD bus (-) circuits CKP and APPS outputs to the PCM Data link connection for DRB scan tool Five volt sensor supply Fuel injection pump Fuel injection pump relay (FPCM) Fuel Pump Control Module Fuel transfer (lift) pump Intake manifold air heater relays #1 and #2 control circuits Malfunction indicator lamp (Check engine lamp) Oil pressure gauge/warning lamp PCM Wait-to-start warning lamp Water-In-Fuel (WIF) warning lamp Another thing to check is the master power connector in the PDC there is 1 bolt that hold it in. This bolt is easy to strip out so be careful of tighten it excessively. Power ground is behind the starter. You'll have to remove the starter to access this connection. You might want to check the status of your alternator and batteries as well. Have the alternator put on a test bench and check the diode pack for function. A bad diode could be leaking noise into the system fouling the ECM and VP44. Check your wiring between the VP44 and the ECM.

-

P1291

Simple enough just take a test light and see if there is power at the 2 heavy leads on the grid heaters when the key is turn on for a cold start... The test light should go out after the WAIT TO START goes out as well. Another way of testing... http://forum.mopar1973man.com/showthread.php/1082-Grid-heater-temp..?highlight=grid+heater

-

Mpg

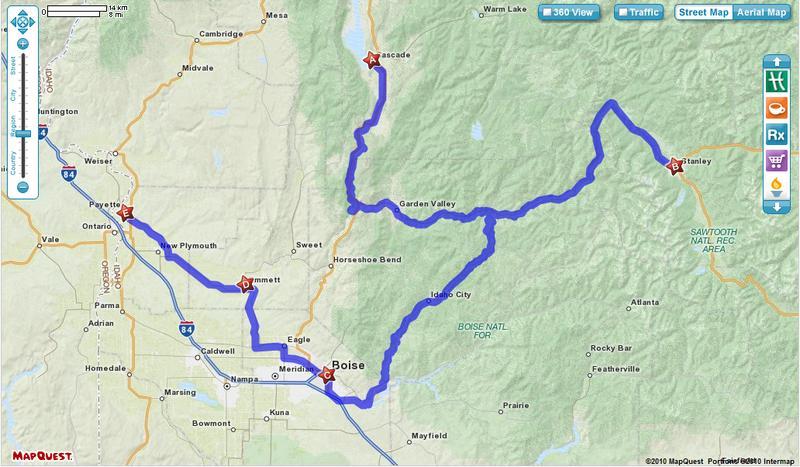

Well I did a trip from Cascade, ID to Stanley, ID then down to Boise, ID. This is all winding canyon roads and hill climbing. When i could better I would typically limit out to 55-60 MPH. 153,549 - 153,197 = 352 Miles / 13.915 Gallons = 25.29 MPG (Copied from my fuel logbook)

-

Issues with an '06

How to dump error codes... http://mopar.mopar1973man.com/cummins/2ndgen24v/obd2-error-codes/obd2-error-codes.htm 3rd Gen code listing... http://mopar.mopar1973man.com/cummins/3rdgen/error-codes/error-codes.htm As for the 2 cycle oil your a bit strong on mix ratio... http://mopar.mopar1973man.com/cummins/general/2-cycle-oil/failure/failure.htm

-

RV275 Results...

SGII works fairly well normally gives very close numbers to hand calculated as long as you calibrate it and make sure your spped is dead accurate... These 2 numbers are critcal to getting the SG II to display close to true numbers. Mile Per Gallon Calucation Speed (Miles Per Hour) / Fuel Usage (Gallons Per Hour) = Miles Per Gallon Gallons Per Hour Calculation Speed (Miles Per Hour) / Miles Per Gallon = Fuel Usage (Gallons Per Hour) Speed Calculation Fuel Usage (Gallons Per Hour) x Miles Per Gallon = Speed (Miles Per Hour) Now we will use the examples above to calculate MPG form fuel flow and speed. 65 MPH / 4.39 GPH = 14.80 MPG As for my miss... I'm sure it has a lot to do that I got them donated from another member and they already had 400K miles on them... But the funny part is I ran a double dose of 2 cycle oil and the miss is nearly gone! Shocker 2 cycle oil cleaned then up rather well...

-

Mpg

Well you beat me now... My top was 25.3 hand calculated... As for the mild offset it could be a slight calibration error or speed calibration is off slightly... Either way it will effect the out come...

-

P1291

Let me correct your error code... P1291 (M) No Temperature Rise Seen From Intake Air Heaters. Problem detected in intake manifold air heating system. Is your grid heaters actually working? I would double check the fusable links in the battery lines and then double check the relays to be sure the voltage is passing the solenoids (bad internal contacts). Then I would phyiscally check the grid heater for a broken elements...

-

Senior Citizen Kicks Some Butt

That's what is wrong with today... Nobody gives anyone any kind of respect... Now if the colored guy would of been repectful of his elders (as I was taught) it would of been just fine...

-

Military testing of 2 cycle oil in diesel fuel

Hmmm... That's really odd... As for the sticky stuff I wonder if you not getting enough EGT to burn the oil off? Possibly over mixing? Poor brand of oil?

-

Killer Dowel Pin

It's not like a old gasser style damper that required a puller... The Cummins damper just bolts on then take it off as far as I've seen...

-

Military testing of 2 cycle oil in diesel fuel

No I don't... But I've check the exhaust brake for full returns on the arm and so far it always opened up...

-

dodge nv4500

As far as I know all years with a NV4500 had this issues...

-

Clutch Install

Normal... Because of minute angle and alinments it tough as hell to slide a transmission all the way in. But mine did the same thing... As long as the bolts tighten easy and did it even I wouldn't worry much...

-

its beat to death but i gotta ask , lift pump issues uhhg

Actually I'm thinking the spring on regulator is too weak on the FASS... Call your dealer and I'm sure they got some different springs. Even I've heard this issue with AirDog pumps too... Like on my personal AirDog pump I pulled the regulator spring out and used a washer with the proper OD and ID sizes and shimed the spring up.

-

dodge nv4500

Ummmm... The only thing I knew of was the 5th gear nut problem... But as for myself with a 2002 I've got 162K on the clock and still going without a transmission problem.

-

2nd vp44 still no pump fuel to injectors

Easy to check... Take the crankcase vent off and turn the alternator pulley with a ratchet and see if the gear moves...

-

Military testing of 2 cycle oil in diesel fuel

Closing in on 100K miles worth of 2 cycle oil usage and still zero issues... That includes the exhaust brake... Yeap... I got to admit Dorkweed being the lead man to get the 2 cycle oil craze started but after doing the study work on it... It really does work good... I've not lost any MPG's over it or performance...

-

RV275 Results...

I trust my SG II and/or Garmin V more that my odometer even though its only off by 0.5 MPH.

-

Killer Dowel Pin

Think that bad just doing a KDP tab??? Just wait till you have to do a gearcase and including pulling the cam out for that...

-

clutch issues, and a emergency brake light issue

As for the clutch there is no adjustment. as for the stiffness feeling I would say it time to pull the transmission down and take a peek there could be several issues like a bad pressure plate, throwout bearing problems, etc. Now is the BRAKE light flashing or solid? Solid is a porportioning valve issue.Flashing is a E brake pedal problem.

-

Custom Quad Headlights w/ HID Bi-xenon Projectors

Man I got to say I got to give you props for this much! Wow!

-

2nd vp44 still no pump fuel to injectors

The only thing I can toss out there is the VP44 error code list and diagnostics... It might give you a clue... http://mopar.mopar1973man.com/cummins/2ndgen24v/vp44-replace/vp44-error.htm Then here is the wiring of the VP44...

-

Mechanical fuel pressure gauge line

Ice maker??? Actually that is a VDO oil pressure gauge line...

-

3 Guys and a tractor...

Here is some real redneck music...:lmao2:At least its diesel... http://www.youtube.com/watch?v=OsrxYKm1htY

- Buy, Buy American Pie