Everything posted by Mopar1973Man

-

Help! The wifes truck died and thru a 1689 code

Check the fuel pump relay in the PDC if it fails it will trip a P1689... Here is a daignostic write up for VP44 error codes... http://mopar.mopar1973man.com/cummins/2ndgen24v/vp44-replace/vp44-error.htm

-

Glow shift gauges

Copper tubing is known for failure because of all the vibration they been know to break under the hood... As for my old line it last 6 years without much problems (unless I broke it off pushing on it) but the new stuff I'm using polyon air brake line is nearly instructable now... I've got a chunk on my desk I've been playing with folding and bending and it just doesn't fail... Remember the phrase... "Dodge makes it Cummins Shakes it!"

-

runs louder?

I don't think so... 225K miles is LOW miles really... you might want to talk to CajFlynn (closing in on 800K miles 2001) and then talk to Taz (630K miles on a 1992)... As for the sound of the engine most of them have quite a bit of clatter which is normal for most engines... As for the -.002 on the valves I know a few that done this and its still with spec so I'm rather sure there is no ill effects of being slightly tight.

-

Senior Citizen Kicks Some Butt

Geez...

-

Mechanical fuel pressure gauge line

Yes sir... Directly plumbed to the back of the gauge for the last 6 years and never had a issues with it leaking in the cab... Still dont...

-

question for 01 owners with Hydro boost

I normally just bleed the brakes at the wheels... But I've got a mayo jar setup with a vinyl tube going into it... So this allows my to bleed the system by myself. Now for getting air out I've just setup on the farthe wheel (rear right) and worked my way towards the shortest (left front). But now bleeding the system I would push down hard and quickly and let up slowly on the pedal. This action pushes the air bubble down the line with the fluid but keep it from sucking back up the line because of the slow return rate. Here is another write up... http://mopar.mopar1973man.com/cummins/general/brakes/brakes.htm

-

Floating NV4500 gears

It suggested not to do this... Because what is occuring is you slamming the syncros together and forcing the match the speeds under road loads. Must will report that syncro lifespan is shortened...

-

2-Stroke oil and Powerstrokes

It doesn't hurt it... But it will keep the fuel system lubed up and retard wear of fuel system related parts. The few times I've used it on a 6.0L you won't notice a huge change but it should become more quiter and a bit smoother running...

-

How to clean a turbo

Like on Taz's truck I pulled the turbo completely off and cleaned both side exhaust and compressor with brake cleaner then blow dried it with compresed air...

-

Giving Big Blue the Edge

At any rate I would make sure you get all the information about it before you order it... Have them double check the information on it...

-

its beat to death but i gotta ask , lift pump issues uhhg

No it not sealed up... The fitting just unscrews out of the body... (return line fitting) As for warranty just remove the shim before returning for warranty work...

-

ScanGuage 2

Correct... The Addon box or programmer alters the data and forces the new values apond the system but the ECM and VP44 are "powerless to change the data"... So in this light the SG II will work just fine because the fueling data and speed data can be calibrated too. Where the stock "Overhead Idiot" is fixed for stock tires, stock gearing, stock fueling, etc... So if you modify any of these things then the overhead idiot fails to report accurate data... Where the SG II can be re-calibrated to the new data...

-

clutch issues, and a emergency brake light issue

My master cylinder was leaking internally bleeding pressure off back to the resivoir causing the clutch to re-engage at will... I never had a leak outwards to cause loss of fluid but the seals wore out internally and allow for the pressure to bleed off...

-

Giving Big Blue the Edge

Edge Juice has the gauges and bunches of toyz (high idle, limits, cool down timer, etc.)... But I'm not certain that you could use most of them being its design for Dodge wiring... Where the only 3 connections on a Comp is the VP44, MAP and the CanBus...

-

Giving Big Blue the Edge

OBDII is not required... Its the CANBUS that comes out of the ECM (Cummins protocol)

-

Giving Big Blue the Edge

I would contact Edge Performance and see what they say... I'm sure they could help you out for sure... http://mopar.mopar1973man.com/cummins/manufacture/manufacture.htm Liker my Edge Comp is extremely easy to hook up... 1 lead to the CANBUS near the ECM. 2 leads to the MAP sensor (boost fooler) 1 lead to tap the VP44 2 leads for power and ground. My basic install write up... http://mopar.mopar1973man.com/personal/2002/edge-comp/edge-comp.htm

-

Cutting out surging bucking

If a APPS is bad it will always throw a code P0121, P0122, or P0123... So now go back and check your error codes...

-

Issues with an '06

Or the alternator could have a bad diode feeding AC noise in the wiring for the ECM/PCM causing them to wig out...

-

Issues with an '06

I would check the alternator and the batteries... I've got a feeling you got a issue in your charging system...

-

ScanGuage 2

Yes... Because what matters is the GPH (flow rate) and MPH (speed) to make MPG numbers... Edge Drag is tapped like my Edge Comp and everyone thing of just because it tapped that the ECM can't see the signal... This is untrue... The ECM can see the change in signal but can't alter it. So the Edge pushes the fuel pulse forward in time and extends the pulse length. But the ECM still seeing this so it not being lied to really... It being pushed beyond it normal limits.

-

Issues with an '06

It cycle the key on-off-on-off-on in less than 5 seconds... It should work...

-

Military testing of 2 cycle oil in diesel fuel

Kerosene is really hard on the pumps...

-

Cutting out surging bucking

The funny part is that the Cummins engine really has very few sensor and things to go wrong... ECM connections... http://mopar.mopar1973man.com/cummins/general/ecm/ecm.htm Inputs Accelerator Pedal Position Sensor (APPS) Volts APPS Idle Validation Switches #1 and #2 Battery voltage Camshaft Position Sensor (CMP) CCD bus (+) circuits CCD bus (-) circuits Crankshaft Position Sensor (CKP) Data link connection for DRB scan tool (FPCM) Fuel Injection Pump Control Module Engine Coolant Temperature (ECT) sensor Ground circuits Intake manifold Air Temperature (IAT) sensor Manifold Air Pressure Sensor (Boost Pressure Sensor) Oil pressure sensor PCM Power Take Off (PTO) Power ground Sensor return Signal ground Water-In-Fuel (WIF) sensor Outputs CCD bus (+) circuits CCD bus (-) circuits CKP and APPS outputs to the PCM Data link connection for DRB scan tool Five volt sensor supply Fuel injection pump Fuel injection pump relay (FPCM) Fuel Pump Control Module Fuel transfer (lift) pump Intake manifold air heater relays #1 and #2 control circuits Malfunction indicator lamp (Check engine lamp) Oil pressure gauge/warning lamp PCM Wait-to-start warning lamp Water-In-Fuel (WIF) warning lamp Another thing to check is the master power connector in the PDC there is 1 bolt that hold it in. This bolt is easy to strip out so be careful of tighten it excessively. Power ground is behind the starter. You'll have to remove the starter to access this connection. You might want to check the status of your alternator and batteries as well. Have the alternator put on a test bench and check the diode pack for function. A bad diode could be leaking noise into the system fouling the ECM and VP44. Check your wiring between the VP44 and the ECM.

-

P1291

Simple enough just take a test light and see if there is power at the 2 heavy leads on the grid heaters when the key is turn on for a cold start... The test light should go out after the WAIT TO START goes out as well. Another way of testing... http://forum.mopar1973man.com/showthread.php/1082-Grid-heater-temp..?highlight=grid+heater

-

Mpg

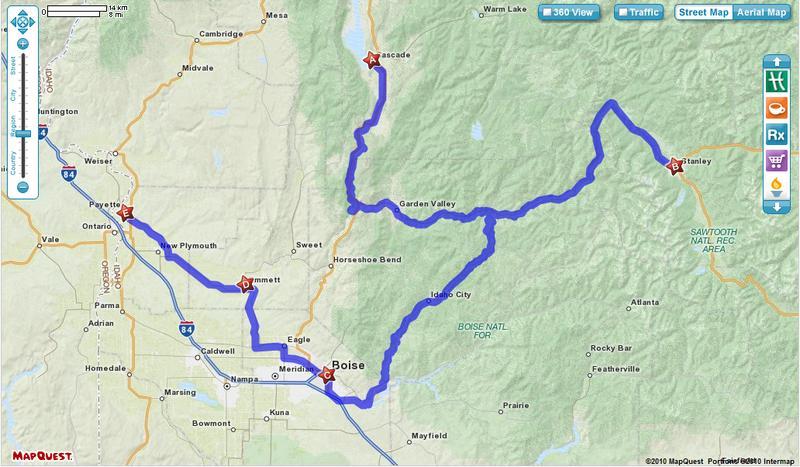

Well I did a trip from Cascade, ID to Stanley, ID then down to Boise, ID. This is all winding canyon roads and hill climbing. When i could better I would typically limit out to 55-60 MPH. 153,549 - 153,197 = 352 Miles / 13.915 Gallons = 25.29 MPG (Copied from my fuel logbook)