Mopar1973Man

Owner

-

Joined

-

Last visited

-

Currently

Viewing Category: Cloud 10 Computers

Everything posted by Mopar1973Man

-

Quadzilla XZT issue.

Don't call Cummins or Dodge for a APPs sensor... It will cost about $400 buck (or $760 Canadian)... I would call either Jocob Kidd Diesel Auto Power (which happens to be a vendor here) or contact Timbo Directly for a Timbo APPS. They are costing $160 bucks for a replacement... http://mopar.mopar1973man.com/cummins/2ndgen24v/apps/apps-replacement.html

-

Rubber brake line from Hydroboost

Then its a low pressure return line just stop by a NAPA store and get a chunk...

-

Big line question

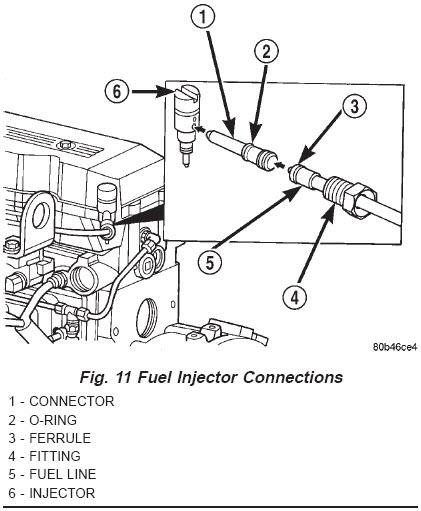

Yeah it does... But remember there is only going to be flow from this return only if the injectors are firing... If the injectors don't fire the no return... The 2 pics show the return line from the head and the tee connector...

-

its beat to death but i gotta ask , lift pump issues uhhg

Ouch... Well let me give you a link for reading material... http://en.wikipedia.org/wiki/Water_hammer Snubber or a needle valve prevents water hammer from beating the gauge to death. Because the VP44 tends to open and close valves rapidily so the gauge might be buzzing. This is water hammer occuring live! It quite literally beating the gears against each other. But as for the rapid fall fo fuel pressure it looks like you might need a fuel pump... It should NEVER fall below 10 PSI ever... So I would consider a Raptor or like another member brought up a new setup with Holley HP150... http://forum.mopar1973man.com/showthread.php/1312-Holley-HP150-Installation-PICS?highlight=holley (New idea)

-

Quadzilla XZT issue.

Ok here is a tidbit... http://mopar.mopar1973man.com/cummins/2ndgen24v/apps/apps.htm Now take notice the APPS sensor has 2 idle validation switches. If the switch states are in the wrong state high idle, exhaust brake, and idle RPM's will be wrong... But the funny part is the APPS will still show 0 TPS on a data tool. But it more important to get the state of the switches correct. Now I'm going off on a limb I don't like to... 1. Is the APPS old or wore out? 2. Is the APPS producing error codes (P0121, P0122, or P0123) If ANY of these thing are occuring replace the APPS sensor... http://mopar.mopar1973man.com/cummins/2ndgen24v/apps/apps-replacement.html Your going to need a DVM... Now as for the APPS idle validation switches they are done electronically inside the APPS sensor. They detect the voltage of the rheostat and determine if its at idle or not. On the back of the sensor is a tage with voltage on it. You wan to check the voltage of the APPS at the ECM (not the PCM). Then using the set screws adjust the voltage till you hit your mark. The wire color and pin number are listing on the pic above... There is several write ups about the Torx screws in back and moving the sensor. Don't bother with that... Just use the set screws on the front much easier to do... As for the voltage double check it after flicking the throttle rapidily if the voltage changes a bunch at idle then the APPS is most likely wore out or wearing out... But if you flick the throttle and the voltage is still set at what the sensor tag shows your good. Now do a APPS reset and try it again...

-

its beat to death but i gotta ask , lift pump issues uhhg

Is it a electric sender gauge? If so does the electric sender have a needle valve or snubber before it? If not the replace the sender. _____________________________________ If the gauge is mechanical the I would be cvhecking the lift pump soon... _____________________________________ Now stock lift pump have been known to slip the plastic hub inside the rotor head...

-

apps sponge

Got any APPS error codes? Battery cables and grounds good? Remember the ECM & APPS ground is behind the starter. To inspect it you must remove the starter... Alternator noise from a bad diode?

-

Electrical issue seemingly resolved - might be useful to someone else in future

Actually I heard a rumor that some states might outlaw audio car alrams and might switch over to silent alarms only (Low Jack and simular)... Out here in Idaho nobody locks ther cars/truck... The key are always in the ignition... Vehicle thief is extremely rare... Because the fact is there is only 1 road north and south so if you steal a vehicle you not going to out run Mr. Motorola... As for all the fools that come from Boise, ID and set the car alarms we sit here and laugh or arses off because the kids around here love to set them off... As for my my alarm... It well rather silent... But rather deadly... You get in my truck you got to deal with 80 pounds of Dobbie coming at you...

-

Still hearing stock lift pump after Raptor Install

If its like my AirDog 150 then the stock pump is dead and your hearing the Raptor pulse at key on. Mine will bump the gauge to 15 PSI and fall. This pulse is normal and typical of any fuel pump controlled by the ECM. Basically the stock pump on the block should be disconnected and no longer used but you can remove the pump and plumbing from the old system but you need to leave the mounting plate there. That mounting plate covers the hole in the block form the old school 12V pump.

-

Rubber brake line from Hydroboost

If its got hose clamps then its low pressure... If its got screw in fittings (flare) then its high pressure...

-

Just lost my 500 GB hard drive...

Well I got back from Boise, ID and got my replacement drive... WeeHaw... 1.5 TB worth of hard drive... Now back to loading it back up with stuff... I'll take the old drive down to the shop and see if I can get if fired up ot back it up...

-

no radio

A lot of people are asking how to pull the fuse from this black clip... (So they can keep it). If you don't want to mess with the clip you can toss it out and push a normal fuse in the hole...

-

Clutch Install

I'm going to be right behind you for testing too... I know I need to buy trans fluid and chnge mine but I'm going to hunt for a good price & product...

-

Electrical issue seemingly resolved - might be useful to someone else in future

You own a Cummins they don't use Ford parts! (Duct Tape and bailing wire)... Yea... That would do it... To thicken up JB weld just mix it up outside in the cold and the epoxy will remain thick... But it might take some time to cure being cold... (Remember) you door light will be on during this time it might be a good idea to pull the batteries wihile it cures... Don't forget to reset your APPS afterwards...

-

TC Lockup

Like myself I would be doing it for the MPg's reasons. Like my Mom's 96 Dodge Gasser is constantly jumping around gear out here with every roll of the highway. It would be nice to lock it up like a manual and let cruise pull it over the hills in top gear instead of dropping lock up, then dropping from 4th to 3rd spinning a bunch more RPM's and then climb the hill (1/10th of a mile) then shift back to 4th and lock up again... Now I know why I bought a 5 speed... But I would like to hold the lock up on the 96... Like climbing dirt roads that trans keeps jumping from 2nd to 3rd remaining unlocked. But funny I can pull the hill in 3rd in my Cummins and not think twice... The other bonus if done right and you watch your trans temps it should reduce them... There should be less thrashing of the fluid from the TQ conv because the lock up.

-

Big line question

I'm not sure... But there has been talk in the past that the VP44 has a small vane pump in it but how much pressure, suction, volume it capable of producing is totally unknown to me. But from what I've learned so far is if the truck is coasting then the injectors shutdown (VP44 doesn't produce line pressure). So this means that the overflow valve must be venting... But theat hard to measure return volume while cruising down the road... So maybe in your case the overflow valve is a bit weak opening at 13 PSI and venting back to the tank... Or that little vane pump is giving it that extra 1 PSI to open the overflow valve... (speculation)

-

Clutch Install

I got to admit that $20+ a quart is hard to deal with... I know the last 2 quarts I bought are from the dealer at $23 a quart... That hurts the pocket knowing its 1 gallon needed for a change. I know I'm due for a change of fluid too...So if your willing to be a test subject... Go for it... I'm about ready to try something else too... I just don't think I can swallow $23 to $25 buck a quart...

-

Silly question...

Being my BHAF filter has most of its life in dirt road and never had a Outwears till someone gave it to me... I've got a filter minder plugged in the head of the filter and its not moving but I do test the filter minder for function. 6 years and 112K miles and only owned a Outwears for 1 year... Even at that rate I paided $40 bucks for the filter so thats $6.66 per year for the filter. Not bad and I got a new one sitting on the shelf waiting for that other filter to finally fail and plug up... I got Taz hooked up with a BHAF on his 92 and we found out because of it pure huge size it not able to hold dust on the media for long. It tends to shake off the excess dust on a bumpy road like head up to the Ranch on a 6 mile climb on a 1 lane dirt forestry road... His now is 2 years old and still looking good...

-

Electrical issue seemingly resolved - might be useful to someone else in future

That a quick easy fix... Another thing you could do is mix a thick batch of JB weld and put a thin pile right there... I doubt that will wear away as quick as the duct tape but still soft enough not to wear the switch tip...

-

VP44 Poll

Been there done that...

-

Safe fuel pressure

I never thought about that... But yeah its true they are always dry...

-

Just lost my 500 GB hard drive...

Thanks I feel the love... Yeah your about right... No error codes... Just a hung screen (dead pedal) and then Bam! - DEAD HARD DRIVE (VP44)... All BIOS report is the hard drive is BAD and need replacment (CHECK ENGINE LIGHT)... Seagate must be getting hints from Bosch...

-

Just lost my 500 GB hard drive...

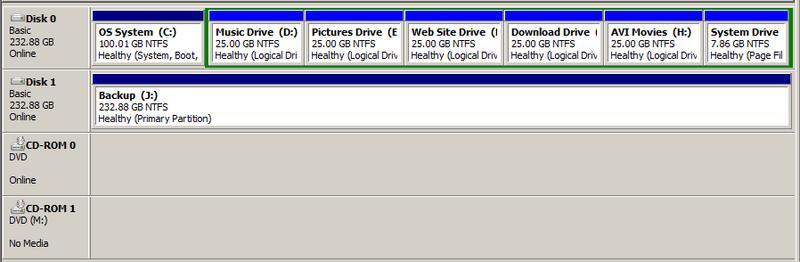

Ahhh... I'm covered there... My main drives are twin 250 GBs... The first 250 GB is split to smaller partitions and the second drive is a mirror image of the first drive... So my main stuff is fine...

-

Just lost my 500 GB hard drive...

Actually I did lose much for data but it was my big work drive that I toss everything into to work on then store on the the smaller partitions... So actually I didn't loose much just lost a nice large work area... As for life span it just past it warranty and died... Typical huh...

-

Big line question

I think I mis understood the last post... I was assuming coasting/deceleration conditions with <14 PSI of fuel pressure... (re-posted to clarify). If you coasting down hill or decelerating... There is no fuel pumped to the injectors if there was you would be accelerating or maintaining road speed. The injection pump is literally turned off. So there would be zero return from the line at the back of the head. The only time fuel returns from the rail is when the injectors are fired (bleed off pressure) is drained to the return rail. This small bit fuel is the remain of fired injectors and bleeds off the line pressure and drain into the return line. So since coasting/deceleration tends to shutdown the VP44 from firing the injectors that means that return rail will be dry and if the fuel pressure is below 14 PSI so is the overflow return line. (except what will ooze out of the 0.16" inch bleed hole...)