Everything posted by Mopar1973Man

-

Nationwide Weather

Been running the heat pump for since about Sept 20th. Been dropping down low 40s here. Where I'm working at in McCall is getting quite cold too in the morning. So I get to try and sleep in being we all start later at almost 9am. This is to allow frost to break.

-

Degree wheel VP44

Interesting. Hopefully your new controller does not have the tiny boost to fuel table.

-

Black Smoke After Rebuild

The only thing I think you might check is the key in the VP44 pump shaft is it installed correctly with arrow towards the pump. Make sure the number matches the number on the case. Typically with timing slightly retarded it will smoke. Like myself I'm right about 19 to 20 degrees on the Quadzilla. This is a limitation of the Edge tuner. Running 150 HP injectors with little to zero smoke. Everything else seems to check out good.

-

So,.......I bought it. New to me 5'er

Nice RV. Funny part the floor plan in the kitchen / living room is very simular to my 2000 Jayco Eagle.

-

P1689 Very hard to start after VP44 replacement and ECM reprogram

The VP44 shaft nut should be torqued to 125 foot pounds. The 4 mounting nuts should be torqued to 32 foot pounds. Always remember Dodge makes it, Cummins shakes it. Yup it takes some torque to hold it all together.

-

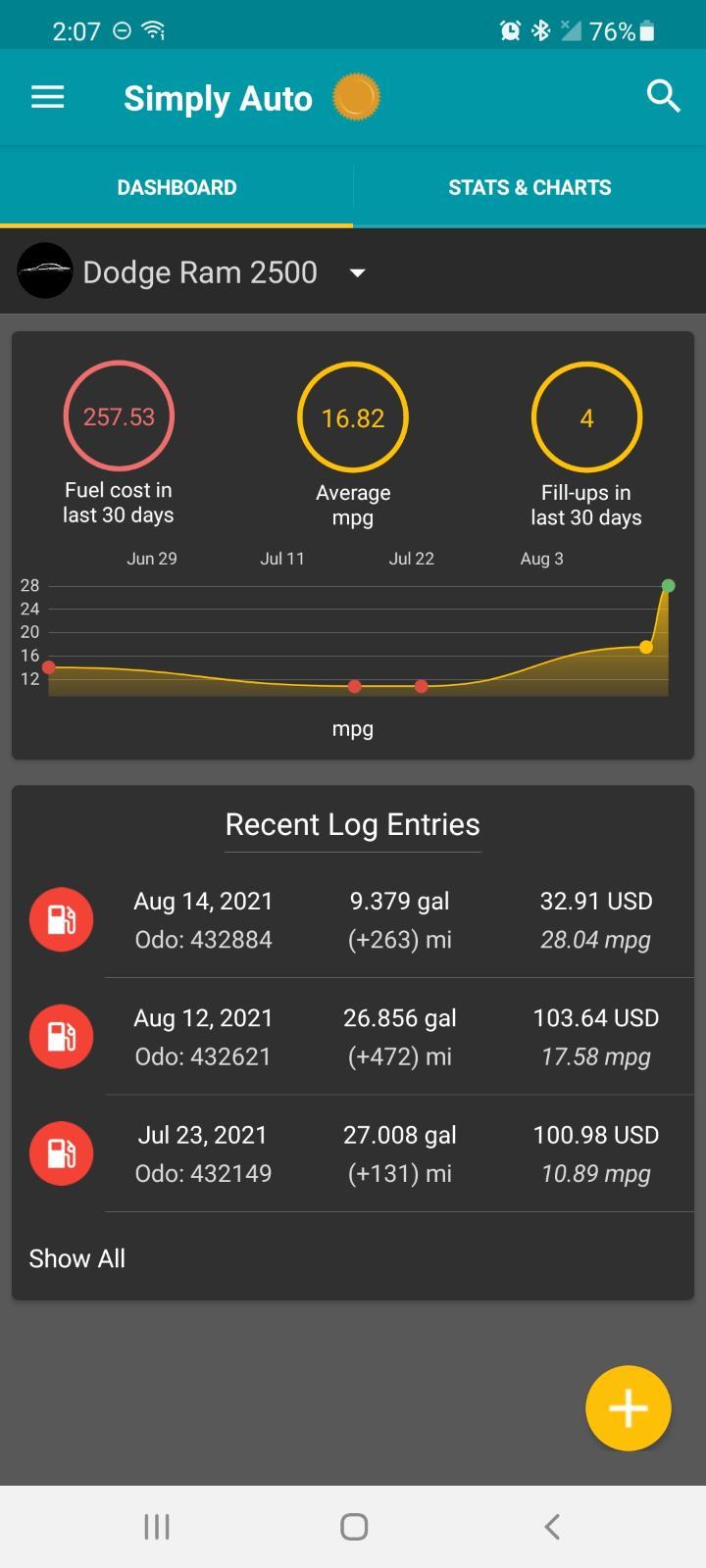

Have we met before? :P

Yeah when your clearing 250 miles on a just a quarter tank or 425 at a half tank is pretty impressive. My last high mark was done on Edge Comp and +50 HP injectors at 27.2 MPG. The ultimate record is catching the 1997 Dodge 3500 on Diesel Power Magazine that cleared 30 MPG. It can be done it just takes skill driving and know what it likes. For example I've got Jake here and he off and on borrows Thor to drive when his Ford is down. I (myself) can reach 20 to 21 MPG on the over head which hand math turns about 17 to 18 MPG. When Jake borrows the truck he hes get like 17 MPG on the over head but this is actually 14 MPG. This 15% error is from the +50 HP injectors in Thor give this error amount. On the 2002 Dodge I did pop the injectors high at 320 bar. This improved the spray and make the droplets smaller. Being the pop pressure is high it makes the injector slightly late. So on the Quadzilla I had to add a bit more timing to make up. 425 miles on just a half tank. Just doing rough math here in this photo. 425 / 17.5 = 24.28 MPG.

-

Spongy brakes and Brake and ABS lights on

Crazy idea try unplugging the ABS Module. See if the boom is gone.

-

Spongy brakes and Brake and ABS lights on

Yeah the boom noise it not typical. I'm now trying to figure out in my mind what it could be. I've only seen one other truck that did this.

-

Runs rough when warm, mixing diesel and oil

Interesting. Yeah get back again when you have the pump back in and tell us what you got going on.

-

So,.......I bought it. New to me 5'er

I would look towards an axle flip first like @IBMobilesuggest. Then once on top of the axle then like he said you can shim up with cut chunks of springs but I think you might barely gain enough to get the tail from dragging.

-

Have we met before? :P

Welcome to the family. I'm also a 2002 and a 2006 Dodge Cummins owner. I prefer the 24V 2nd Gens over CR trucks. Way easier to work.

-

Truck has issues steering only to the left

Yup it sound like the spool valve has debris in the valve. So when you turn to the left the valve opens and applies pressure to the piston ot aid in turning since the left side is weak then you'll need to remove the steering box and disassemble the power valve assembly. Be aware you might pull the worn gear out and if so you'll have to count 22 ball bearings and reload the worm gear with the 22 ball bearings. This is done under the cover of the sector adjustment. Might give @Blue-Top Steering a call and he can guide you to fixing this as well.

-

Another NV4500 failure.

First off let me say. I just had my transmission fluid change this summer. On my trip to Lewiston ID I had the Quadzilla on Level 2. I made it to the Casino outside of town and stop for a minute to grab a few things. Pulled back out on the highway rowed up through gear and it started clicking. WHAT?! Any gear had a very loud clicking noise even neutral as long as it rolling. I figure out pretty quick its was the input gear from the input shaft. Towed it home and pull the transmission. Yup you can twist the input and feel the gear is got broken teeth. NOTE: Remember the Quadzilla was on level 2 (stock fuel), fluid was just changed this summer and fresh and full. When I drained the fluid is was still clean but full of fine glitter. Now I opted for a different trans builder. I got a connection with a builder up near @Dynamic up there in Northeast Washington. The gents name is Jason Hammer. He dove in and looked over my transmission basically I wore the hard facing off the those gears with over 435k miles. Totally normal wear for those gear and distance since those gears never been changed. Now the countershaft is one unit and will be replaced as a full unit. I'll post up the carnage as soon as I go back up north 5 hours away to get my transmission. .

-

Few random questions..

Weird I can run much lower in oil temp but being the oil levels where low it might make a difference. I typically float at 160 to 170*F engine oil temp with the sensor in the test port of the oil filter housing. I know this is the cooled oil from the oil cooler. Typically more advancement the higher my oil temp gets. When I've got my timing right the oil temp falls and drop to this lower levels. Kind of like my fuel temps are never higher than IAT temp and typically match for temperature after hours of driving. Coolant typically rides at 192*F to 197*F with a 190*F NAPA thermostat. I must be doing something right for 425 miles at a half tank. Gotta remember all the factory final ratio, tire sizes, rotational mass, etc. All impact the load on the engine. Any heat created in different places is sign of wasted energy that is converted into heat. Any high temps are a lost in efficiency. Even my trans temp is low.

-

Spongy brakes and Brake and ABS lights on

You might have to get a ABS coder reader and see what the codes are being its a very random issue. Mine in the past was a bad tone ring in the right hand bearing in the front after replacing the wheel bearing both sides the code reset. Basically in a nutshell all 3 speed sensor (both front and rear axle) have to match to make the lights go off. Typically though the fronts are the source of the cause because if the rear was a problem the speedometer would act goofy. Meaning... The speedometer might sit at zero for extended period and then pop up later after movement started. Again this would be a bad rear sensor if so. ABS communication is not common so its special tool to read the ABS code. Even my Innova code reader has the function but not compatible with our year of Dodge. I heard that boom on one other truck which is some sort of after market device. This is not something that is normally heard.

-

Suggestions for injectors, turbo, head gasket.

Well I'm not have any problems and comparing @Sycostang67truck versus my own with the tires and current injectors his pulls good with the Edge CTS but very smokey. No way to reduce the smoke on his truck since I installed the 100 HP injectors. He also runs higher on EGT's. Remember I'm bigger at 150 HP injectors and very low smoke and at least 200*F lower EGT's.

-

Spongy brakes and Brake and ABS lights on

First off... Does the speedometer work properly? If the speedometer works correctly then the rear sensor is fine but the front to are suspect. I've seen bad tone wheels in the unit bearings cause a ABS/BRAKE light. But other than that its one of the 3 sensors. Best to replace both fronts the same time. Typically if you replace one sensor the other old sensor will trip because it will not match speeds with the new one. Once you fix the ABS problem all you gotta do is turn the key on, start and move about 100 yards with a bit of speed and the light will reset on its own. Might check for error codes it might give more clues make sure to use a OBDII coder reader and not the key trick.

-

Adrenaline will not initialize

I've had mine have a weak ground which caused bucking initialize issues.

-

Adrenaline will not initialize

Double check your ground too.

-

W-T ground wire mod - Simplified

I've done over a dozen W-T ground wire mods. I just measure voltage drop between the battery and block. Now I just add jump cables between battery negatives and so far on ALL the trucks I've done this too there is ZERO gains of parallel grounds between batteries. It does not change voltage drop or AC noise. The current flow does NOT use that parallel ground UNLESS on of the OEM grounds is bad on one side or having high voltage loss then you'll end up over loading the remaining cable with the parallel setup. I don't suggest it.

- 35 comments

- 5 reviews

-

Adrenaline will not initialize

The newer head does both the WiFi and Bluetooth both. I've been beta testing on my truck and works really well.

-

Cutting Out Under Hard Acceleration/Above 68 MPH+ 2500 4x4 47re

Yeah the few that called me installed a sump then ended up with leaks later and now replacing the entire fuel tank. Very hard to find good fuel tanks in a salvage yard. I do not suggest or recommend a sump on any truck. Top draw is the best. The biggest problem no one knows out to properly install a straw. The first thing is measure on a empty tank ONLY! Make sure the entire tank is empty! Now lay a quarter (coin) on the bottom and measure to the thickness of a quarter. This is the tightest tolerance now. ONLY cut straight! No weird cuts at 45 or anything else. Now with the tank coming empty the straw will be able to draw up the last bit of fuel. Now on a full tank diesel is roughly 6.1 pounds per gallon. That roughly 213 pounds of fuel this will cause the bottom of the tank to deflect downward another roughly 1/4 to 3/8 of a inch so you'll never suck the straw to the bottom. I've been set up this way for over 15 years and never had big problems with getting to the EMPTY mark.

-

EGR & DPF DELETE

Basically the retard timing of common rail I've got the same thing on Thor (2006).

-

Front Headlights suggestions (Assembly and Bulbs)

Be aware LED lighting will snow over in northern state and not clear. The HID can be snowed over but it takes much colder and heavy snow fall to cover over typically. Like my PIAA LED light will snow over being they do not create much heat at all.

-

Turbo and injectors recommedations

Between getting the final ratio to 3.69 to the ground, with 30 inch tires (245/75 R16) then the injectors and the tune. Just look at my dash photo. Not many can do 425 miles at half tank.