Everything posted by Mopar1973Man

-

New 2022 3500 Dodge Tradesman 6.7 HO Aisin ordered and coming in the fall ???

Yeah I know... really thin...

-

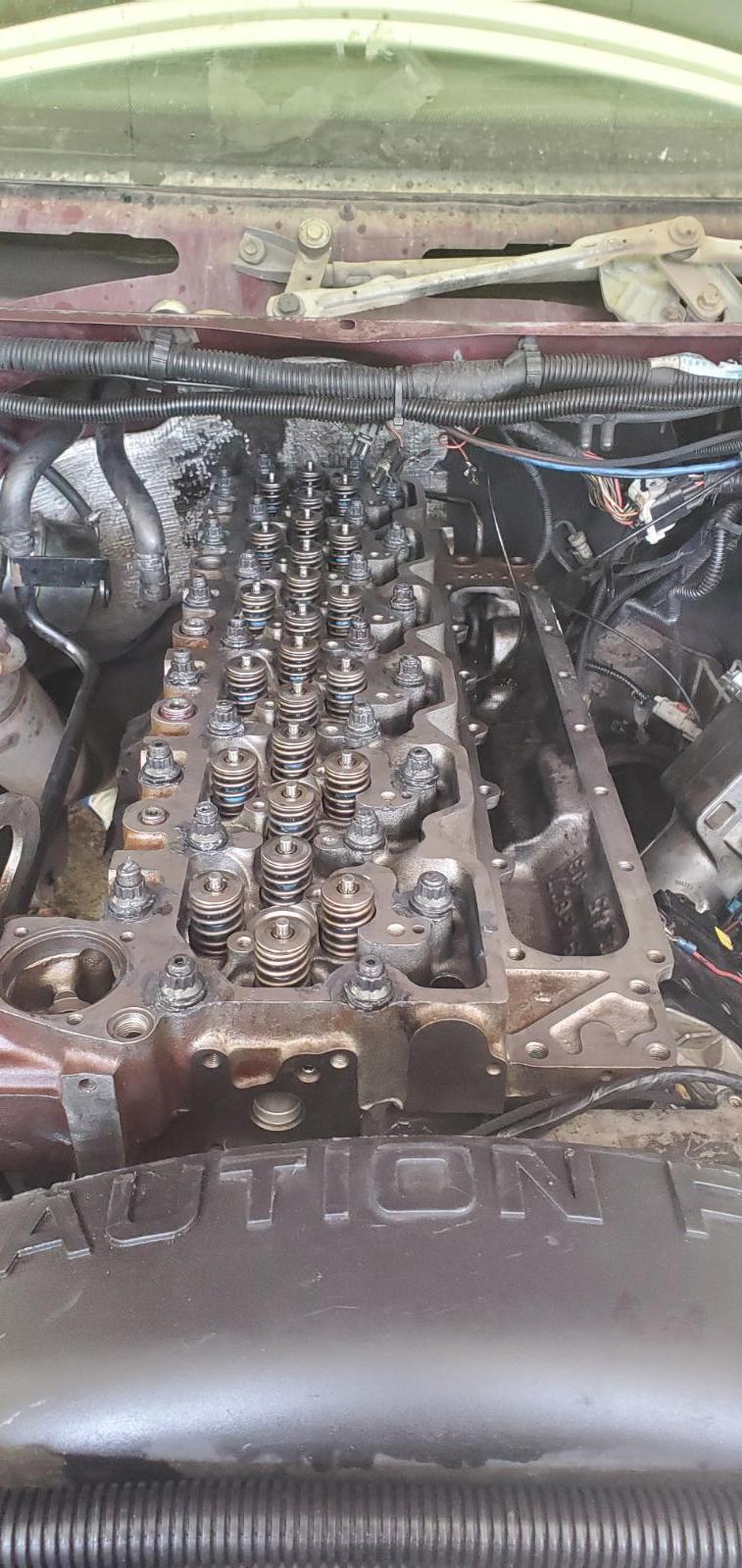

Replacing head gasket

Correct. You must place the head then install the studs. The longer studs go on the exhaust side of the head. There is one that won't fit between the cowl and the head. I use a floor jack and lift the passenger side of the cab (not the frame) it will lift the body of the rubber mounts to gain that 1/4 inch needed to slip in the stud.

-

Starter quit!

Back to running. I pulled the clutch safety switch. Jumped it. Nothing. Then grabbed the test light and nothing. I went out to the fuse block (TIPM). Started testing fuses and found one blown. Changed the fuse. With the clutch jumped it started. Now the hard part of putting clutch safety switch back. Fought with the plastic pin to line up the clutch shaft and the pedal to push it back through. It started. Should of check fuses first...

-

Pilothouse/RAM3500 build

Getting itchy to see this truck completed... But you can't rush good artwork!

-

New 2022 3500 Dodge Tradesman 6.7 HO Aisin ordered and coming in the fall ???

Wow. Learning something new. Kind of like some of the new cars I'm seeing with 0w-16 oil being used.

-

2008 MC 6.7 - Derate Issues

The pop off counter is what I'm looking at. Something told the ECM that rail pressure was too high and popped off 29 times to bring it back down. Then it acted like the valve stuck open long than needed which now the ECM records that fact the rail pressure is too low now for 43 times. Just think things out a bit... If it was a derated for emmisions you should not see the high pressure pop off. Still in all the ECM should not derate so deep that the rail pressure drops out to trip the low pressure message. Like with the 2006 I've got when the waste gate solenoid had broke wire it derated but just enough that boost was only 20 to 25 PSI roughly. After fixing the wires it picked back up to normal power but never let the rail pressure drop complete out to trip errors. Possibly is the tune making the high pressure pop off message?

-

Boost Issue

More you retard timing the better it will build boost. Too many people are too concerned with getting enough advancement. This why I suggest starting 1,500 RPM band at 13 degrees. Then if you have enough timing reduct it should be able to pull down to 10 to 11 degree on a heavy throttle or WOT. Once boost build it step back into advancement and continue to build power. With 15 degree in the 1,500 RPM band you might notice with cruise timing running and light throttle it might buck at lower speeds 30 to 40 MPH. The 13 degree at 1,500 RPM will reduce that chance of bucking as well.

-

Truck randomly dies. Please help, pulling my hair out, and loosing sleep!

Make sure to do it right... If not set right it will be on the wrong mode of IVS (Idle Validation Switch). I highly suggest getting a Timbo's there is NO VOLTAGE ADJUSTMENT. It all done by bellcrank angle being there is no electronics in a Timbos APPS. Inside a Timvbos APPS as you can see there is no electronics to foul up the signal. As you can see in the stock APPS it requires electronics to monitor APPS voltage to toggle the IVS switch for the ECM. These are known for issues and electronics failures.

-

Replacing head gasket

Head gasket job isn't too bad. This is my second time on Beast. About 2 hours to pull the head off. About 4 hours to adjust everything and assemble. First time I need 18 valve guides and new valve seals. Cost $2,000... I had a member drop $200 on my bill! Thank you to that member! Second time was much cheaper. Only $480 bucks for the machine work to resurface flat. 0.006 warp from end to end. Also new valve seals. Head installed with ARP 425 studs.

-

New 2022 3500 Dodge Tradesman 6.7 HO Aisin ordered and coming in the fall ???

Personally I just stick to the common 15w-40 but lot of people think they can extend the life on synthetics. Too many hotshots out there running petroleum that make extremely high mileages without any worry.

-

VP44 Injection Pump Teardown - How it Works

Sorry gang. It was a server module problem I had misconfigured. Basically it was suppose to see the picture and determine that it needs compression so it converts JPG, etc into a better format and got stuck. Then leaves the photos missing. Refer back to this months newsletter.

-

Starter quit!

Possible... ill be working on it in the morning. I'll post up what I find.

-

Truck randomly dies. Please help, pulling my hair out, and loosing sleep!

Absolutely.. remove all the other ground mods.

-

Starter quit!

2006 Dodge - Starter issues Just got home for lunch and now going to move the truck to get a job done. There is nothing. No click nothing. All the dash lights up. Being this is controlled by a TIPM I'm not sure at this moment what to look at next?

-

Truck randomly dies. Please help, pulling my hair out, and loosing sleep!

Need more info... The ECM if its not booting up the wait to start will not come on nor will the engine start. If the ECM circuit for the lift pump is burned up it will not supply power. This is why most switch over to FASS or AirDog and get the protection relay so the power is supplied by a relay and not the ECM. If your lift pump plugs directly into the ECM plug then its very possible for the ECM lift pump circuit to be burnt by a shorted lift pump. We have those in stock...

-

Well pump running 24/7........

Neat and interesting...

-

Well pump running 24/7........

If you can I would. Might get a few hose timers and set up two different watering systems. Then I would set it up to water in the night. Run one for a few hours and swap to the second one and run for a few hours.

-

Replacing head gasket

Still running stock valve springs on the Beast.

-

2007 3500 Okay Deal?

75w-90 would be a good lube for G56.

-

Replacing head gasket

Just need a quality head gasket and at least ARP 425 studs. I'm pretty close but have a smaller turbo. (60/60/12). The only thing you can do is pull the head and have the head checked for cracks then surfaced flat again. You might have the valves, guides and seals looked at. Oh, welcome to the family.

-

2007 3500 Okay Deal?

Sorry... Personally I'm going to switch away from the ATF and look for a true GL-4 trans fluid.

-

Help, looking for comparable trucks for sale… insurance co is not even close

Heck I've got a neighbor that wants to sell his truck for starting price of 25,000 for a 2001 Dodge. Bit high in my book but the amount of monies invested is quite large.

-

2007 3500 Okay Deal?

I remember my old Southbend Con OFE use to have gear rollover noise till I changed from stock 75w-85 trans fluid to Mobil 50 SAE trans fluid. As for the G56 it's still running ATF+4. Even that doesn't have the gear rollover.

-

2008 MC 6.7 - Derate Issues

I'm assuming this is all the high pressure rail pressure being what the display says. I would consider the pop off valve as a replacement maybe its sticking in the open side?

-

2008 MC 6.7 - Derate Issues

@Rogan got you covered.