Everything posted by Mopar1973Man

- Parler?

-

Parler?

No. As long as every plays nice and not verbally abusing other members and not threating violence, im all good. Just suggest it stays in the Politics club. That's it.

-

New DAP 100HP SAC 7x9 injectors

-

Parler?

Same here, just dunloped over my belt.

-

Pcm voltage issues

W-T ground mod handles the ECM and VP44 grounds. Thats the first thing to do.

-

New DAP 100HP SAC 7x9 injectors

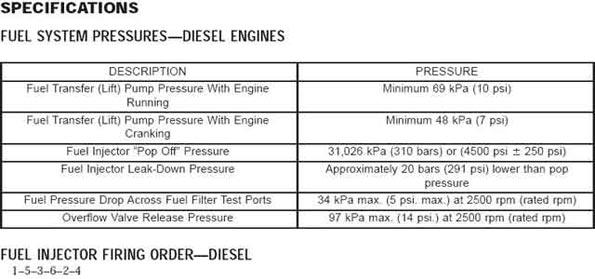

I've seen another member pull his injectors after 28k miles and they fell to 280 bar. He sent the injectors back to re-popped to 315 bar IIRC. Might talk to @pepsi71ocean he could tell you more.

-

Parler?

Just like this morning listening to the BS news off of Eileen's phone and just shake my head. Unbelievable the BS and lies. How about all the Antifa and the riots that Democrats started last summer?

-

Pilothouse/RAM3500 build

Yeah I am too. You know @PilotHouse2500 is a master of his craft here. Slowly taking his time to fix every bit of metal to work for the build.

-

New DAP 100HP SAC 7x9 injectors

I would send those 100 HP injectors back for pop testing under warranty. I know a lot of injector builder have set there pop pressure lower 300 to 305 bar (4,351 to 4,423 PSI) to increase the fuel flow. Myself I went the other direction. I'm running 7 x 0.010 popped at 320 bar (4,641 PSI). It does make a difference in MPG and longevity because the bottom limit 293 bar (4,250 PSI).

-

Electrical questions/troubles

Been that way for months now. Just a simple Fan Belt for a 2003 Dodge Dakota took 1 week to get from NAPA.

-

Had to tow a broken ford today

Wow!

-

Cutting Out Under Hard Acceleration/Above 68 MPH+ 2500 4x4 47re

Not if you install my method you'll never have an issue. The biggest thing NEVER direct plumb a fuel pressure gauge. At the tap point you need both the needle valve (safety) and the sintered metal snubber. Then you need at least a minimum of 5 feet of 1/8" air brake line. If you can use more that is great longer the better. The distance from the VP44 tap point has to be far to fade out remaining pulses. I've never had a fuel pressure sensor failure yet. Mechanical are the same you need the same snubber and valve but you have the distance into the cab. All you got to do to kill a fuel pressure sensor is install it directly at the VP44. The pulses will beat it to death in mere few months and be leaking by then. My design is to give my line distance from my tap point plus making the testing of the sensor much easier. Again you need a minimum of 5 feet of 1/8 inch air line for that reason longer is better.

-

Had to tow a broken ford today

That is why I love this particular video.

-

Had to tow a broken ford today

AC noise can hit ANY vehicle and create all kind of weird issues. Not just Cummins trucks...

-

Had to tow a broken ford today

I've only can remember one time that happen. Was my 1978 Dodge Motorhome had 10+ year tires on and lost 1 inner dual and one out dual on both sides at the same time. That was the only time I can remember having to call a tire company for flat repair. My fault for running old tires and going cross country to MN. So far knocking on wood I've only had flat tires with my truck and never had any tread separations or explosive blow out.

-

Electrical questions/troubles

When I'm looking fort parts I typically check the NAPA near me, then start working out from there getting to vendors I have agreements with and then maybe check Rockauto. I will admit RockAuto tend to have good prices but for me the shipping is the killer some times could be weeks to get parts. So RockAuto is the slowest answer. NAPA is the quickest answer but can be expensive. My vendors typically is a 2 to 3 day shipping time but the prices are typically better but the inventory could be limited. Kind of like yesterday I'm playing with a 1985 Chevy Suburan with a over fueling issues and MAP sensor code 33. Now I'm calling every where to find a MAP sensor but those old school sensor are hard to find up here.

-

Cutting Out Under Hard Acceleration/Above 68 MPH+ 2500 4x4 47re

This why I created the sensor bracket I did so testing is super easy. I just unscrew the sensor add a tee hook up my mechanical gauge and drive. I can do the same thing with the boost sensor too. No digging at the block and fighting to change sensor for test gauge. Losing prime etc.

-

Parler?

I was and uninstalled I wasn't going to start all over again. So I deleted the app and quit using facebook. Everything out there is censored, moderated, and most the info is complete BS. Heck even watching the lies pour out the mouths of the news stations.

-

Red Head Steering Box

Because of a warranty issue. Found a nick in the output shaft causing damage to the seal. I sent it back to have the shaft replaced and new seal put in. Still the same box just repaired. I found the problem 2 years ago but with daily trip to Ontario I could down the truck back then so I hang in and got it done this winter. So it only my second box since 425k miles and the same Blue Top box just replaced the shaft and seal. Still doing better than most folks.

-

Cutting Out Under Hard Acceleration/Above 68 MPH+ 2500 4x4 47re

I hate to guess at parts and blow good money on part that might not be it. Im leaning towards the VP44.

-

Cutting Out Under Hard Acceleration/Above 68 MPH+ 2500 4x4 47re

Ok here we go. From pin to pin (matching color wire) there should be a perfect 0 ohms from point to point. Failure is 5 ohms of greater. Then you leave both unhooked and do pin to ground. This check for wires that are shorting to ground possibly. This should turn up INFINITE ohms for all test but if there is any resistance then that is a fail because there should be no connection to ground if both ends of the wire is open. We do have affiliate program with Quadzilla.

-

Cutting Out Under Hard Acceleration/Above 68 MPH+ 2500 4x4 47re

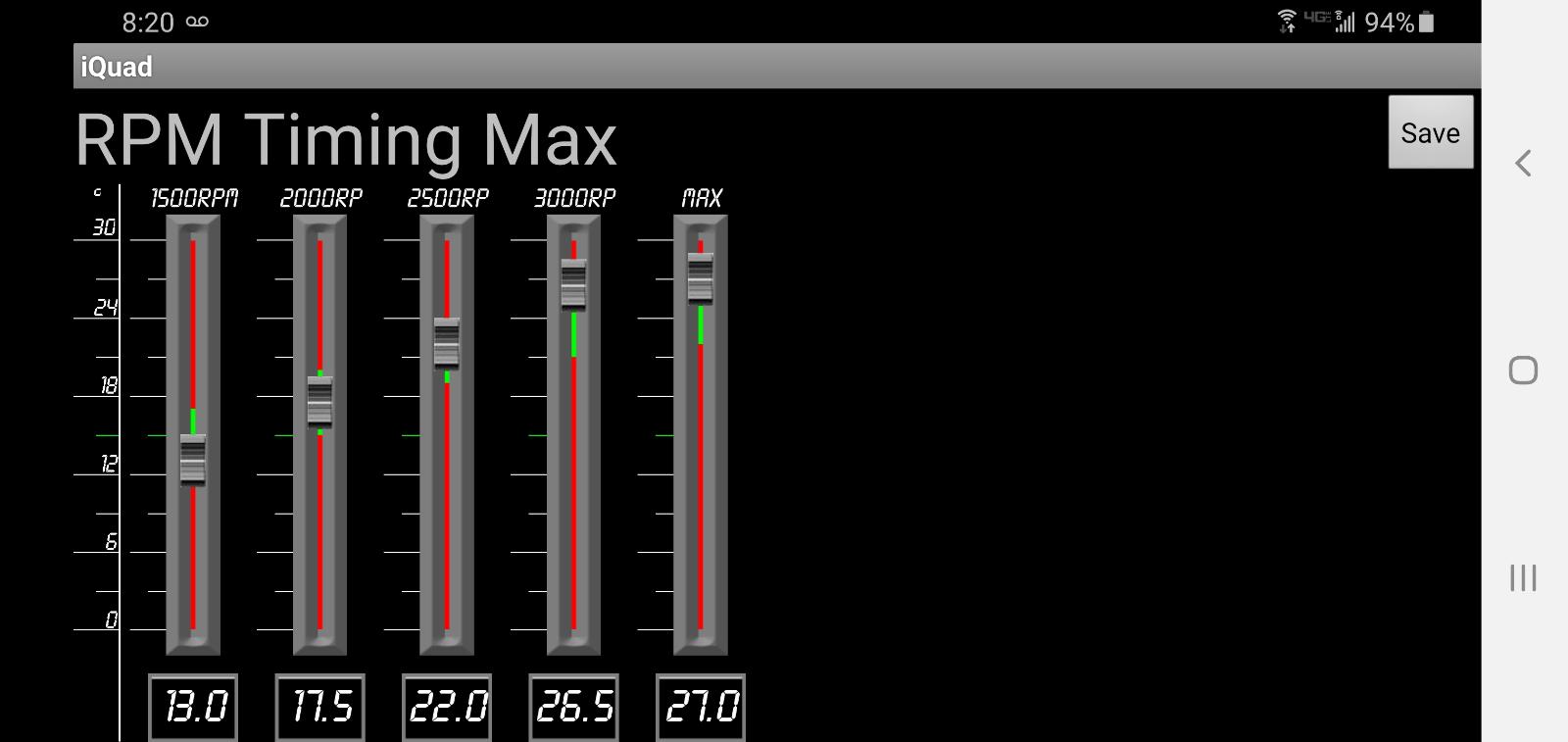

Which is possible too but typically when a VP44 go funny there is codes with it. Hence why I asking for pin to pin ohm test between the ECM and VP44. If the wiring is all checking out then you got to get another clue that point or give reason for expensive parts. Sad part is some times you have to let the problem mature a bit more to show its ugly head. Cutting out is electrical so I would say monitor your Engine Load number for sharp drop off. One of the perks about Quadzilla it doesn't have to be in the vehicle to watch live data. I can have my truck warming up outside and leave my phone on my desk and monitor all system functions from the comfort of my desk. Once you get a live data tool of some sort we can look at the data you've got. Quadzilla would be the best because you could data log a trip with the cut out and it would show up in the data logs so you can see everything that happen the very moment the fuel drops out. Just an example from @Me78569 data repository...

-

Cutting Out Under Hard Acceleration/Above 68 MPH+ 2500 4x4 47re

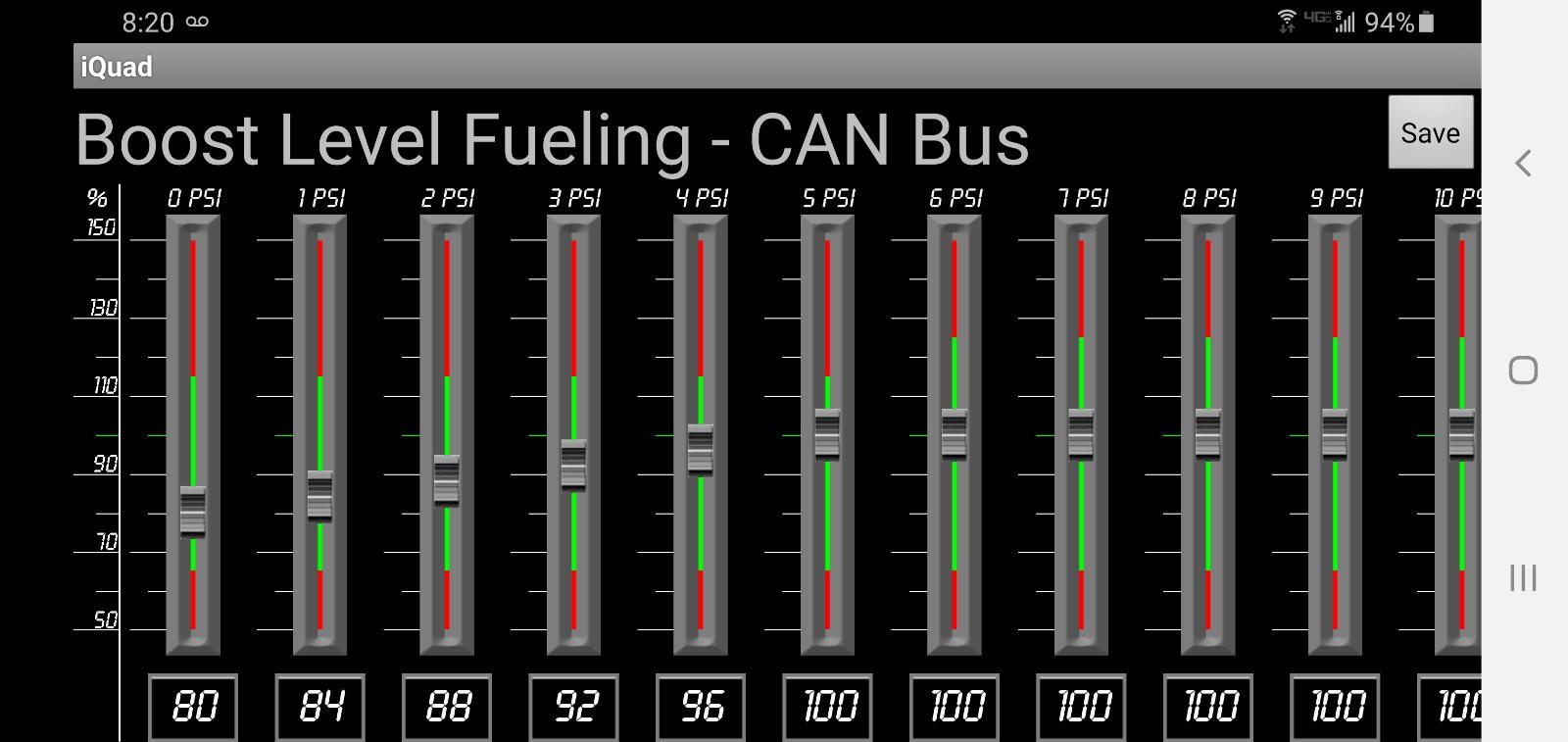

I've gotta ask does this cut out occur also with cruise set? I got to know are you manual transmission with fly by wire cruise or automatic with vacuum cruise? What I like to see if your manual if cruise is set and doesn't happen then the problem is around the APPS. You could pin to pin ohm test from APPS to the ECM and the VP44 to ECM and verify the wiring is good. Still in all ECM controls what the VP44 is going to do. I don't suggest that at all. You could get a live data tool like a OBDLink LX or MX tool and then watch the live data on the CCD Bus. Watching the TPS values for dropping out or sudden changes in engine load (fueling amounts that cut out). You can do the very same without calling the dealer and paying $120 to $150 an hour. Personally not worth it. Smarty S-03 is limited to on 60 HP gain, no real timing or fuel control unless you step up to Smarty Touch but that is $1,800 tuner and now you'll have all those features but still limited to just 60 HP gain. Now Quadzilla provides full fuel, timing and other functions that Smarty can for tuning for fraction of the cost. Being I worked for Smarty for over 3 years and played with a few product I'm not impressed. Basically like @Me78569points out all Smarty does is turn the throttle into a light switch by 30% TPS signal Smarty is pouring fuel at 100%. Now compare... Full timing map Then fuel CANBus fuel map all right on your phone. No PC needed, no flashing the ECM to make adjustment (Quadzilla does this in REAL TIME). Way better tuner over Smarty S-03 or Smarty Touch. Sorry to say. No. Smarty can't read DRBIII code nor can Quadzilla only a Dodge Dealer Star Scan can. You can see my defuel curve and my step up to stock fuel in my mid power range. Completely configurable and way more control over the engine even right down to warming up and cooling down (turbo timer) which Smarty does not have in either product. Quadzilla can't read codes but can follow way more live data right up to seen the commanded timing for the Injection pump. Something Smarty S-03 can't do.

-

Cutting Out Under Hard Acceleration/Above 68 MPH+ 2500 4x4 47re

Matter of fact I just released a Zero Boost tune for Quadzilla that has a good street manner but on the upper end it will pour on the power if needed to pass someone. 7 x 0.010 +150 HP Injectors HX35/40 Turbo Estimate on MPG is somewhere near 19 MPG at this time. Still in BETA testing of the tune. There is much more options for getting good MPG without beating up the transmission. If you purchased a Quadzilla I could build a good tune for what you have. Just shows you don't have to stay stock and get MPG too.

-

Zero Boost Tune

Kind of in a nut shell we all have been ramping from 0 PSI up to 30+ PSI in some form of linear ramping of fuel. How about ramp up to stock fuel hold stock fuel for a span and then just up sharply to build power on the upper end? So far I'm very please with the way this tune has functioned. It will hold the turbo at 0 PSI boost for nearly everything. Rolling hills you gotta watch closely to barely see the needle wiggle off the zero mark. Don't let this tune fool you turn the wire tap on and put the pedal down hard she with hit that 15 PSI and the power comes on sharply with both the wire tap and CANBus ramping up together Smoke free tune be serious power on the top, bottom end launching is fairly strong, middle of the road not bad. Drives like a you turned the Quad down to level 2 or level 0. Mild street manners as long as you don't get that turbo excited, once that happens you better hold on. WARNING! - Again this tune is NOT designed for... Racing Towing Heavy cargo hauling This tune is design for daily drivers, that need passing power on two lane roads but cuts back to a mellow driving stance even with the manual throttle. Being the tune hold the boost down considerable it does tend to heat the EGT's a bit more on grade but even in my run yesterday I never exceeded 800 to 1,000°F EGT's. WOT going for broke in Level 3 it comes to rest right at 1,200°F EGT's. Just remember my tires and final ratio do promote lower EGT's than most.