Everything posted by Mopar1973Man

-

Acceptable AC voltage with grid heaters on

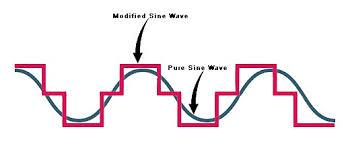

Difference... Solenoid spike is true it does make a sudden spike but... That's not the one I worry about it the the constant generation of high AC noise from the alternator as long as the grid heater is running. This is due the high current load on the alternator the load is typically higher than what the alternator can produce at an idle so the diode heat up and AC noise streams forth in to the rest of the truck. I understand that spike too being if I hook up the lighted switch on my exhaust brake it will blow the LED light out in fraction of a second being the spike from the exhaust brake solenoid for the vacuum control is big enough to blow the LED out. But after 423k miles I realize the fraction of a second spike is nothing its the constant generation of the AC from the diodes that is more damaging. If solenoids were the true downfall it would of wipe out way more than Dodge. Ford uses the same solenoids for glow plugs, starter solenoid, etc. Even our Starter is a huge solenoid that pulled the contact plunger into the battery contacts to spin the starter. Like being exposed to a single gun shot (the single BANG) vs. a full automatic just rattling for hours (BANG, BANG, BANG, etc.) the single bang you recover pretty quick but listening to hours of it will most likely ruin your hearing. Just like the ECM and PCM a single shot pulse is nothing it will absorb the single hit. But hours of rattling AC noise will kill any computer. I could pull this sideways a bit. My home inverter is called a Modifed Sine AC inverter. It is not a pure sine wave. It a stepped up and down. Tons of people told me don't use it it will destroy your electronics in your house. Nope not true. The sinewave even though its noisy its clean enough to be used. I'm still running the entire house on this inverter over 25 years. So how much noise is allowed is hard one to place a limit on but cleaner power is always better. But some ripple and noise isn't the end of the world either being like I just showed after 25 year I've never lost an device in my house. Even my PC is older than dirt and needs replacement still using every day and working the site. Little info on my Trace Inverter... http://nooutage.com/tr.htm#:~:text=The Trace series Inverter%2FCharger,in an off-grid application. Take it even farther... I've installed a Harbor Freight 1,200W inverter in my RV. Another case where everyone state don't use on electronics because it will kill it short order with dirty power. It been installed for better than 5 years and used every camping trip and still have the same TV in the RV 5 years later no issues. Charged my cellphones and other devices on that power too. Just food for thought...

-

Rear Main Seal

What a mess... Wow! Fresh bearing and a lot of clean up I don't see why it wouldn't work. Cleaning is going to be the biggest time sink.

-

Sorry Everyone I haven't felt like participating much Lately.......

@dripley you've been in construction for years and will always love to build things. Like myself I've been turning wrenches since I was 14 years old. It when I get free time to work at my own pace and the project I want to do are the most fun. Not looking forward to power steering pump but oh well. It the fact I can turn wrenches on my own truck and enjoy my day. Now the twist in all this is Jacob (Eileen's Son) which is highly interested in mechanic work too. So I've got a apprentice to follow me around and willing to turn wrenches for me. This why the injector job on his 7.3L Ford truck. Doing on the low budget method of pull and clean injectors and reseal them. Going to be fun pulling the 7.3L injectors for the first time. Nope never done injectors on a Ford 7.3L yet. At the same time do the grow plugs too. Kind of like that... @dripleyit doesn't matter what your building or what challenges await you it the fact of the challenge that keeps you going. I'll still admit there is some things I've never done before, willing to tell a customer even too. Then go out and find that it wasn't so bad. Still get the job done. So for you I don't think you ever get that out of you after all these years. You'll still want to build or make something better around you in the method you know best. Construction...

-

NV4500 Clutch & Input Shaft Question

Whoa! Before you make another step. What size tires are you running? If your larger than a 31" tire DO NOT do the quick ratio box! Quick ratio box can be used on tires and wheels smaller than 31" inch. If you do install it will cause the box more stress being it too low of a gear ratio to push large tire left and right you need to keep the standard ratio steering box. Again do not opt for "quick ratio steering" unless your stock or smaller. Just the same issue with oversize tires on 3.55 axle gears, making the final ratio too low. Like on my 1996 Dodge I'm running 215's tires (30.6" tires) and could easily upgrade to quick ratio. Being I've reduced to 245's (30.5 Inch) tires I opted for the quick ratio box on my truck. I'm running the Blue Top Steering box. Sad to say I've got a warranty claim on mine and will be pulling it back out for Ryan to look at. At 423k miles I finally blew up my power steering pump. It was a OE pump. Shaft issue and leaking. Ryan is going to take care of it for me. Just mail it back to him. I'm running the Valair dual disc. But here we go with tires. If your tires are large your most likely trapping torque in the driveline which typically creates a slipping clutch problem. You need to look at the tire size and look at the final ratio to the ground. For example I drop from 265's to 245's tires with 3.55 gear creates a final ratio to the ground at 3.69:1. The OPTIMAL final ratio is 3.55 to 3.73 to the ground. So with just going to 285's from 265's will reduce your final ratio to 3.42:1 ratio adding drag and stress to the clutch. I'm at 500 HP now and never slipped a clutch but I do slip tires which is absolutely fine being the excessive torque burns rubber instead of spinning clutches or breaking driveline stuff. I've already managed to break a mainshaft in a NV4500 at the 3rd / 4th gear on 235's tires (31.7" tires) and Edge Comp (Metal fatigue). Then managed to break the teeth off 5th gear with Quadzilla on 245's (30.5" tires) at 80 MPH on the interstate. (Metal fatigue)

-

Sorry Everyone I haven't felt like participating much Lately.......

How about yesterday. I dove in and changed an entire 2001 Dodge Ram 2500 steering column, converted from standard steering to the highline with stereo controls. Even got the clock spring changed over without breaking it from one wheel to another. That has to swap because the wiring is different from the standard to the highline series. In a mere 2 hours I changed out my landlord steering assembly and had it all changed over with a newer steering wheel, all the controls, and less one bad steering shaft bearing. Today I get to play with a Ford 7.3L diesel and my truck with steering issues.

-

Installing air springs, hose question.

Just to keep posting going I'm going to tell what I've got in mind. So instead of dedicated screen for back up camera I've been looking at clip rear view camera that record both forward and rearward. I'm actually looking for one so I could do something like @IBMobilewhere the rear camera can be WiFi and remote mount in the rear window of the RV possibly. Then have a second mount on the truck possibly. This covers both forward and rearward views. Already got my radar detector hanging from the rear view mirror and the emergency red light hidden behind the rear view mirror. https://www.amazon.com/TOGUARD-Control-Cameras-Waterproof-Assistance/dp/B0899J7471/ To this day I've never found a really good reason for air bag as of yet. Even towing my big 31 foot RV I don't normally have a lot of front to rear rocking. I would most likely skip the air bag still after 423k miles without air bags. My Mopar1973Man High Idle is hidden in the pouch of the dash. It hangs downward with the knob from the top of the pouch that manuals have. Nobody even knows that is there. Nice hiding spot for the switch. Pouch is still in the dash. Manual CAD cable. Thank gawd I've got solid axles I hate that design and still do... I have guys constantly coming with vacuum issues or CAD diaphragm issues. That one less on my dash. To this day ZERO 4WD issues yet with solid axles. Even on my 1996 With CAD axle I've still got issues with it locking and unlocking the axle. Converted the cigarette light over to USB QC3 ports with a volt meter. I'm going to change the power point over to another USB QC3 port without a display being that circuit is +12V hot constantly. This will get rid of all the cigarette light USB chargers I've got. Like my Radar was a cigarette light powered. I went on Amazon and convert it to a directed wired device. https://www.amazon.com/Cobra-Hard-Wire-Radar-Detectors/dp/B004AMBW1U/ One day I want to do another mod of the exhaust brake switch. The shift rod would be replaced with gas pipe and the wires ran inside the pipe up to the shift knob and have the exhaust brake switch either in the knob or just below with the typical switch. My stereo was a good choice the Kenwood Bluetooth model is really good at playing my music from my phone but just as I bought that stereo Google Play (Music Player) was obsoleted. I had to download a different player to play my massive amount of MP3 files. I got Audify Music Player off of Android play. https://audifyplayer.com/ As for the Kewood playing Spotify or Pandora isn't working correctly being the Kenwood app is not designed for my Samsung S10+ Android 10 software it was designed for older software.

-

Sorry Everyone I haven't felt like participating much Lately.......

I know that feel all so well. It seem like your just a kid a just a few years ago. All you wanted to do is grow up so you could drive, drink, etc. Now you past that markers and it seem like time flies by now at super sonic speed. Hard for me to believe I made to 50 years old. Week blow on by and I'm here going it Friday I can do... OPPS! Actually is Saturday and it closed.

-

Acceptable AC voltage with grid heaters on

Easy pull the alternator field lead (blue and green wires) and see if the problem goes away. APPS being weird the only thing I can suggest is replacement.

-

Acceptable AC voltage with grid heaters on

Not sure about the alternating grid heaters either you could test for that by using a test light and probe the two trigger posts on the solenoids to see what is going one. Still in all the testing should be done on a fully warmed truck that has been driven till full operation temperature. Regardless the first start up the batteries are drawn down deeply between the pre heat grid heaters and the cranking over. This is not a fair test. Again make sure to drive the truck till completely warm and then leave it run and do your test again. This should be unloaded alternator with everything turned off.

-

Acceptable AC voltage with grid heaters on

Go warm up the truck and drive it. Once full warmed up now test. Again with grid heater running and engine is cold the batteries are cold so high numbers are seen. Drive it and warm it up and leave it run now test your AC noise again. At this point the grid heater are disabled and batteries should be charged and engine is warmed.

-

Acceptable AC voltage with grid heaters on

Normal to see the spike but the amount is the problem. Since there is no way to evenly load the system there is no way to test the alternator at home. Like if I turned on everything in my truck with LED lights and HID headlights will have lower load vs your truck. So of course my ac noise voltage is much lower. I can't say only my values work. This where you need to bench test the alternator before leaving the store if it passing then your fine. But yes its normal for AC noise to rise with grid heaters. This is another reason why I unhook mine in the summer no need to add stress to the alternator diodes. This is why we made the home test unloaded so there is just resting alternator and measure the AC voltage. Since there is no way to even load evbery truck and get the same results to the same test. Even grid heaters could fire 1 or 2 elements depending on the temp at start time. IAT controls pre-heat. Then Battery Temp controls post heat.

-

Acceptable AC voltage with grid heaters on

Typically even a store would fail above about 1.2 volts AC noise (not really sure). You might have it tested again and see if it passes of fails.

-

Sorry Everyone I haven't felt like participating much Lately.......

I'm sorry to hear about this. After dealing with my own bladder cancer I really do understand what your up against. Good wishes and all I can say is don't give up. Keep a positive thought every day no matter how bad it gets. As long as you keep your focus on getting better it will give you the strength to endure what your starting.

-

Best injector for "MY" truck?

Like myself I run level 2 on Quadzilla. More or less its stock fuel with your lead in de-fuel curve. More than enough power for daily driving. If I need a booster shot to pass long truck or series of cars. Yup. I tap the Quadzilla up to level 7 (100% wire tap). Then drop the hammer and let her eat. The level 2 is capped out to 100% fuel that all no added CANBus or wiretap. This allows me to be that sleeper truck... Always a bit of fun...

-

Ctm code?

There is a key switch on both sides for arm and disarm.

-

Rear Main Seal

Even with a #5 injector line leaking will make a clutch slip. I'm watching and learning because someday I know I'll find a guy that needs a crank seal next. Matter of fact I should dive into that Ford 7.3L and do a crank seal.

-

W-T ground mod/150amp breaker question

Yeah when I burned up the PCM and I stuck the new alternator in of course it wouldn't charge without the +12V to the field. So I drove from Ontario OR to Parma ID to get to friends place for help. About half way there the volt gauge fell to 8 Volts and chime went off and I looked down at the Digital display on my USB charge port and it just fell from 12.00 to 11.99 volts. It will not come back up till the voltage is back above 12.00 again. It a dead clue something is wrong with that fuse/breaker if the CHECK GAGE light comes on and volt gauge is sitting on 8.

-

Sorry Everyone I haven't felt like participating much Lately.......

LOL... No joke I've got Eileen's Son (Jacob) his 7.3L Ford F350 sitting in my yard with one crappy injector. I'm planning on crawling out in the morning and doing passenger head of injectors in the snow storm that is coming. This should be award winning... Then slide indoors and do the power steering pump and pull my steering box and have it looked at by Ryan. Troublesome output shaft seal. So my truck will be down for some time. Then I got Eileen's son which wants to learn diesel so I've been working with him and letting him turn wrench for me. Small bonus nice to have young blood wanting to learn. Me... I never got anything done today but two trips to McCall for parts and meds for the family. Now I'm wore out and just trying to get warmed up again. Hips and lower back are sore now and just time to quit for the day and let my body heal a little bit. I'll admit still later tonight I will fire up the cannabis and relax just a bit. Right now I'm going to work on the web site and fix more tidbit and get it running better.

-

Quadzilla Timing - wanna share some info.

Start out at 13° at 1,500 RPM and step up +4 or +4.5... Your first step up from 15 to 20 is too wide (+5°) even for my truck. 13.0°, 17.0°, 21.0°, 25.0° is +4° 13.0°, 17.5°, 22.0°, 26.5° is +4.5° Starting out above 14° tend to make the bottom end doggy.

-

Sorry Everyone I haven't felt like participating much Lately.......

Me it mostly all long hour standing under two post lift in weird position because I stand taller than lift can lift. If I work from home its lots of kneeling on bumper and laying over the top or laying under. My next project is a power steering pump. Ugh... So my lower back and my hips are always sore.

-

Quadzilla Timing - wanna share some info.

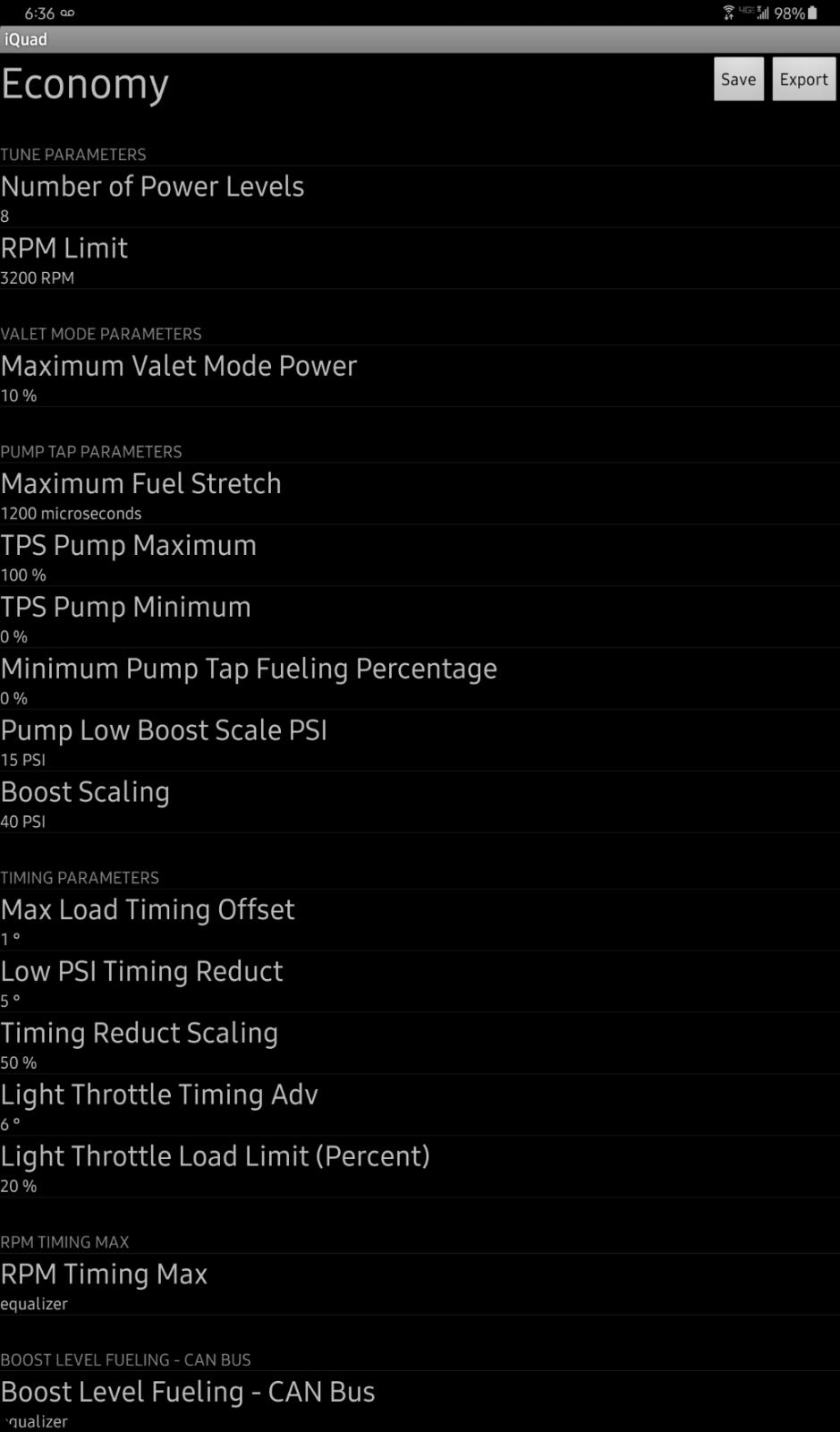

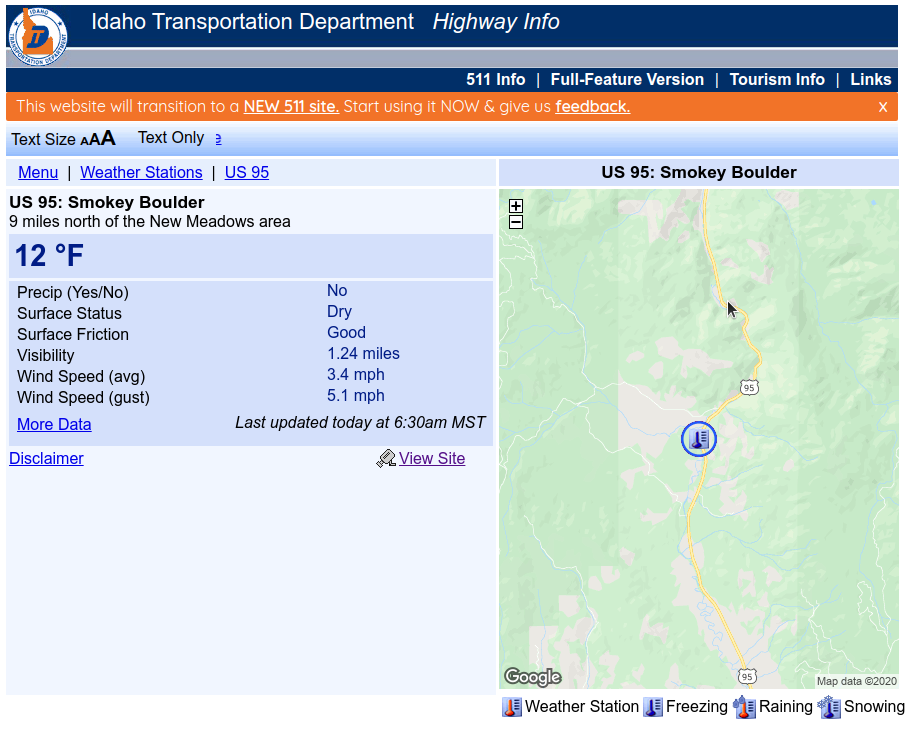

Stock injectors require long duration of being open to make the same amount of fuel. @LorenSYou might want to nudge the cruise timing up some more you notice the engine load may drop a bit more. If you notice the rattle is way more pronounced and then engine load seem to climb a bit your at your limits and need to back down again. Here is my latest Economy tune... Cruise timing at +6°...  I've ran the cruise timing at +4° for the last tank barely made 17 MPG. Now jumped up to +6° cruise timing and now the EGT's dropped really good and the engine oil temp rose about 5° roughly. So now I'm advanced about as far as I want to go. The rattle is more pronounced but EGT's are down, boost is down, and engine oil temp rose slightly. MPG appears to be better now and gaining above 19 MPG rough fuel gauge / odometer math. Here is today's weather...

-

Best injector for "MY" truck?

I've had to wait for exhaust system for a local job because of limited material caused from the COVID-19 shut down. I still have issues getting parts in any timely fashion at all. Even just a fan belt for Dodge Dakota took me a full week to get here. Local stores didn't have it.

-

High EGTs when towing

Yeah that is signs of low pop pressure and larger droplets are hard to burn. Takes more time to heat the droplet to vapor, to make it go BANG! Finer mist always will run cooler and smoother. Lower pop pressure enhances fuel flow, Higher pop pressure enhance MPG and clean exhaust, lower EGT's. People tend to forget the pop pressure is the starting point of when it opens period. The maximum pressure of the injection pump is well above 18,000 PSI at WOT....

-

W-T ground mod/150amp breaker question

Tip: Thew volt gauge will fall to 8 and set the CHECK GAGE light when the voltage drops from 12.00 to 11.99 volts.

-

Sorry Everyone I haven't felt like participating much Lately.......

I know the feeling to certain degree. Being I've been under a 2 post the weird standing positions you create to reach this bolt or that nuts pays a toll on your body. Time to slow down even more Mike. I know you wired the same way I am we keep working till the job is done but it might come at the cost of your body or health. Just slow down.