Everything posted by Mopar1973Man

-

07.5 6.7L Air filter (BHAF)

Yeah I've seen a few do BHAF on 3rd Gens but not many yet try the 4th gen for a BHAF...

-

2006 mega cab 5.9 Cummins with 37.3 volts at alternator?

My first thought is the fusible link in 3rd gens are buried in the loom. Burns out and then you have an open circuit and ECM is applying full throttle to charge the batteries but power never reaches the battery hence the charge voltage would be 30 plus volts.

-

LED headlight bulb suggestions? The industry has come a long way.

Slightly but mostly white. LED bulb temps are a bit different that HID bulbs. What they look like. (Camera shutter speed and aperture adjusted to show the bulb.)

-

What happened to our political parties?

Exactly correct answer. I seem to be doing the right thing. I've got a endless supply of water being my irrigation water is from a creek up behind the house. Then the extra pressure is used in my hydro generator to produce a small amount of power. Then solar panels in the front yard. Then my water is pump right out of the ground in my 50 foot well in the yard. Brilliant photo eh? Clear skies, clean water, and green yard. Right of the photo there is apple trees, then bottom edge there is blackberries outside my front door. Like other things if done responsibly you can do a lot to change thing around you. Biggest thing is everyone wants to jump to the top of the Gov't pile and change things directly. I'm proud that our fore fathers understood enough to write the constitution. Now you have people hoping to jump to the top (democrats) and turn everything up side down. I make my stand with my local fire dept and local Gov't agencies. I do all I can to make changes for the good for even my local community. Here is a good example of Liberal stupidity. Payette Forest charges $20 for 2 cords of firewood. Now they provide a cutting map to tell you which area you can cut and what size trees or... Etc. Not to mention Payette forest goes around labeling trees as a Wildlife Tree and do not cut down. This is liberal controlled forest. Now go north to Nezperce Forest its $20 for 4 cords and any dead tree is open game. No stupid wildlife sign, no species limitations, no cutting maps. Now this is the best option because now everyone is cleaning up all the dead fall or dead standing trees. Needless to say this helps to keep fires from spreading. Where Payette forest has problems with controlling fires.

-

LED headlight bulb suggestions? The industry has come a long way.

The LEDs in my 1996 Dodge Ram are fanless 4,000 lumens. Integrated heat sinks - no fans or bulky braided heat sinks Internal drivers for simple installation 4,000 Lumens of cool white (7200K) light/set Can Bus compatible Lifetime warranty

-

LED headlight bulb suggestions? The industry has come a long way.

Just only buy 4,000 lumens or lower. Less likely to blind people. Higher lumens tend to require fans and can be very blinding. I could order a set of 4,000 lumens in a 9004 bulb.

-

M73M.Com get together at Mopar1973Man's

Yes sir. I do a full leaf and needle sweep typically. But stuffed under the spruce out front. We wanted to move it away from the front gate so we can see people coming in. Currently I'm parked up Smokey Boulder for the weekend. I'm very hidden in the back country. Like myself we got geared up and manage to do a stellar week. Did several A/C jobs and even doing 2 injection pump job. One I've got to run back to Anatone, WA to do a Case backhoe IP. Pay came in bills are covered. Just need 2 more weeks like this one and we will be comfortable. It is a struggle when you have Eileen with her car payment and then me with my cancer payment. Both owe about the same amount and take about the same amount of time to pay off. Once those two fat bills are gone it will be time to slow down.

-

What happened to our political parties?

Since I'm at a level of Govt that working with the cities gov't and fire gov't agencies. I try to do what I can to better the local area. Right now the local USFS is making it impossible to interface with our local fire dept. I always thought to start at home and work with what you got around you to make changes. I'm more or less tired of the BS and lies that the media and the Gov't is throwing out. I realize the COVID-19 is real and does pose a problem but I don't think its worth shutting down the world. Even my world I'm looking to converting to more web base commerce. I'm already doing all my billing through the website and processing payments for job through the site. I can email billing to people and they can pay through the payment portal of the website. Slowly getting my own business rocking now. Thanks to Eileen @Wet Vette for handling the invoicing and bills for the business. The other thing I've seen with my two eyes was my trip down to Mohave Valley, AZ. Did a A/C job for Codie down there. California has taxed R134a Freon so bad that its $26.00 a can 12oz. Then add another $10 core charge per can. That was $103 before taxes for three 12 oz can of R134a freon. Now got to Bullhead City, AZ and freon is only $5.99 a 12oz can no core charge either. This is your democrat laws that has changed California forever. This is that "Green New Deal" crap the democrats dreamed up. Let me circle back to Federal Gov't crap. Now fire season is coming o Idaho things are drying out and fires are starting. If the green new deal is about reducing carbon emissions then USFS should now be playing "Fire Manager". What they do is allow the fire to continue burning till end of season when weather puts it out like a rain storm. This load the sky around here with thick smoke and make is difficult to breathe even. This is LEGAL... But now your going to complain about the diesel truck emitting a bit of black smoke? That is talking out both sides of your mouth. I say curb the USFS and tell them to stomp out the fires than playing fire manager and push it around with senseless back fires and control burns. Another waste of taxes...

-

What happened to our political parties?

Valid points mentioned in your post. Personally I'm not a democrat at all. I would say currently I'm leaning towards Republican. I'm not going to say that Trump is the answer either but it better than anything the Democrats have to place for a President position. Kind of like trucks most of us like the Dodge Cummins we could tear each and every brand apart and pick out the good and bad just like Presidents. I'm also a concealed carry permit holder. I'm fine with the 2nd Amendment its clear on what the law is. Yes I agree people with mental illness or mental disability should not be allowed to have firearms. But remember criminals will never abide by the laws either hence why they are called "criminals". I can say what immigration did to my old neighborhood. I left Mission Hills CA back in 1990. Now today is destroyed. It nothing but homeless living on the sideways and anywhere they can. I'm glad I left that state. Everything is over taxed and too expensive still selling fuel down there at $4.00 and up.

-

M73M.Com get together at Mopar1973Man's

No I'm more bummed that every time you've came do to hang the weather sucked. Now is a good time to be up here highs in the 90's today. Weather is calm and mild breeze through the yard. The spot I'm building out back is under the huge maple tree and the RV stays naturally cool back there.

-

Raptor 100 or 150?

Always go for the largest pump and use the largest hose 1/2" and fitting. You need 1/2" straw in the tank and keep the stock filter and 1/2" big line kit too.

-

Apps question

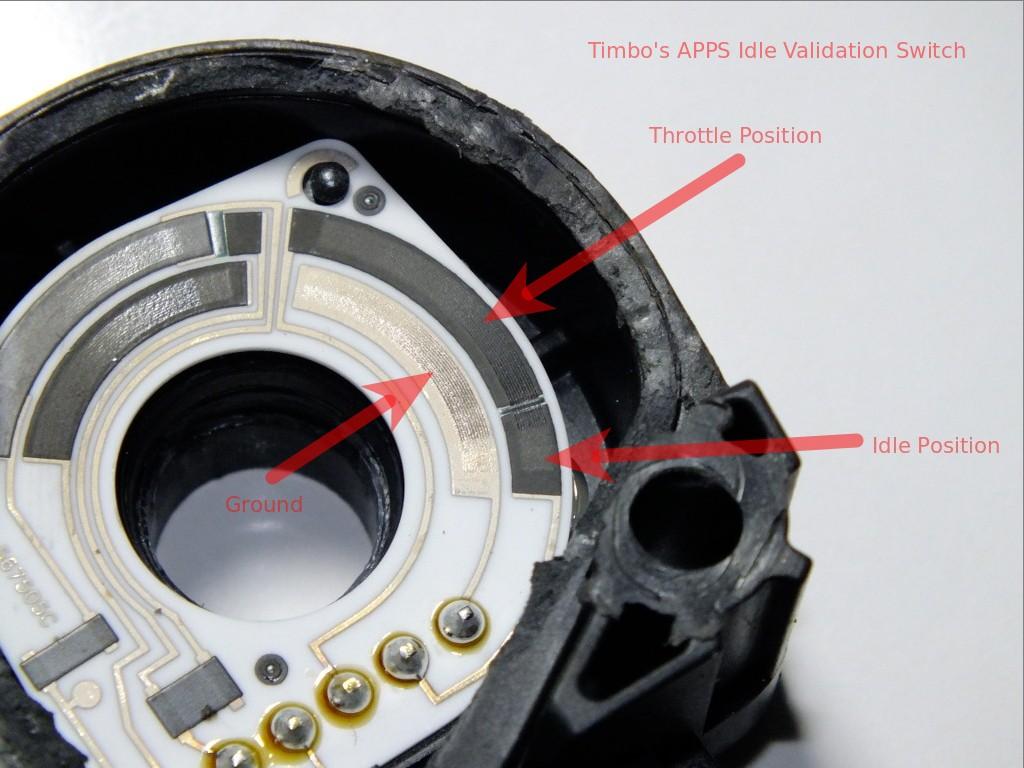

Timbo APPS is a completely mechanical APPS sensor no electronics just a heavy duty rheostat. Even have them in the store...

-

3rd or 4th gen fuel pump in 2nd gen

Rumor is that the 5th gen pumps are actually pretty good. Just need to modify the unit to fit into the fuel tank.

-

New Member

Welcome to the family...

-

Time For New Tires......considering 315/75R-16's on stock aluminum wheels

315's tires make your final ratio 3.27:1 to the ground way too low in final ratio you NEED to change to 4.10 gears to reduce stress on the drive line. MPG number is not correct either being your odometer is no longer close to correct and percent offset don't work either. You need to track mileage with a GPS. Optimal final ratio should be 3.55 to 3.73. Like myself I went from 31.7 inch (235/85 R16) tires to 30.5 inch (245/75 R16) tires and final ratio is 3.69:1. Really hard on the transmissions and driveline.

-

Getting back into the trucks

I worked there for 2 years back as a kid. Van Nuys, CA.

-

M73M.Com get together at Mopar1973Man's

Not me. Last thing I want to do is be stuck at home.

-

Getting back into the trucks

Yup I typically do. Low failure rate typically. All the shops out here use NAPA since there is no Autozone, No O'rilleys, no Pep boys, etc. I have a NAPA in McCall, ID. Then the main NAPA store is in Council, ID. Then there is NAPA in Ontario, OR (no taxes and better discounts), then there is a NAPA in Grangeville ID. Now Ontario have Autozone and O'Rilleys but typically part guys are dumb as posts.

-

Tire Recommendation needed

Been extremely happy with the Hankook ATm... Worth looking into. Harder compound and tire wears like iron. I've been running those for over 250k miles 4 winters and excellent traction in a foot of snow at 55 to 65 MPH. No studs in the tires either. Last set I got two winters out of. This will be my first winter to just stay home. I've got Discoverer AT3 on the 1996 dodge not too happy with those either.

-

Engine surging... at a loss here

I would never use a FRRP pump. First off the stock line size is too small for that pump. Enhanced wear. Pump is too far from the tank. Pumps are not design to pull fuel long distance. Then the pump has no return line so when it dead heading with low flow it cavitation creating air or foam in the fuel. Typically suggest full AirDog or full FASS. More so AirDog since FASS pumps tend to gell up fast out here vs. my AirDog.

-

Time For New Tires......considering 315/75R-16's on stock aluminum wheels

All i can say is swap the axle gears for 4.10s. Final ratio will be too low.

-

Getting back into the trucks

Brake fuild should changed every 30k miles. The fluid has moisture in it and oxidized all the seals hence the black color. Now I suggest you rebuild the whole system. New Master, New calipers and rear wheel cylinders. Look over the metal tubing rust holes or leaks. Double check all the rubber hoses too.

-

M73M.Com get together at Mopar1973Man's

Just starting to add a second RV spot in the yard which will have full hookups by next year most likely.

-

not your typical APPS problem

No! Do not set for the old voltage... This why I'm suggesting the Timbo to get you way from this old method of voltages. It was that Dodge APPS has a logic board to control the IVS switch by electronics ot TPS voltage to trigger idle or throttling. This is all based on the current APPS if replace DO NOT ADJUST. Leave it alone!

-

not your typical APPS problem

That tag voltage number is the break point between 0.320 0.420 Idling ............................ | Throttling...................... > Now you set it so it rocking back an forth between throttling and idling. It is REQUIRED the idle voltage be BELOW the tag number at least 0.1 volt so you need to set it to 0.320 volts to get back in range again. Idling software disregards the APPS value completely and now runs a internal software of the ECM for idle control. Manual truck have the anti stall feature in the software. The Auto do not have the anti-stall. Adjusting the apps never does any good other that fouling up the idle circuit. Hence there is none of that in Timbo's APPS. You can see the zones in the rheostat. Even on the install of the Timbo they ask to measure the TPS voltage and adjust the stop screw till it rises and then back of to that point it started and the loosen the stop screw 1 more turn to drop the rheostat in the idle zone more so.