Everything posted by Tractorman

-

Torque Converter Acting Weird

Actually, that is not weird at all, in fact it is normal when there is stray voltage interfering with electronic components. For example, the PCM receives inputs (some wanted and some not) and makes decisions based on these inputs, such as when the torque converter should be locked or unlocked. When stray voltage influences these inputs, the PCM temporarily keeps track of them and determines whether or not to use them or discard them. If the stray voltage signals are frequent enough in a specific time period, the PCM will use these inputs along with the wanted inputs and make decisions accordingly. That's when the bad behavior shows up. When you replaced the batteries, the PCM lost all of this temporary information regarding the stray voltage inputs while the batteries were disconnected. So, that is why it took a couple of days for the problem to resurface. - John

-

Steering Issues/Cold Weather problems

Are you saying that you cannot turn the steering wheel at all? Or, are saying that you can turn the steering wheel a ways either direction and then it stops. If it is the former, then there is definitely something wrong. It could be many things - a relief pressure setting too low, something binding in the steering linkage, a stiff suspension ball joint, a faulty spool valve in the steering gearbox, etc. If it is the latter, then yes, it could be normal. As far as the power steering pump making noise when it is very cold outside, vane pumps are notorious for making a groaning noise when cold. Many vehicle manufacturers use vibration dampeners on the hoses to suppress the harmonics developed from the pump. I would thoroughly check the hose routing for the power steering pump and the brake booster for contact with the body or frame of the truck. Make sure the mounting of the brake booster is secure. Loose or touching components can easily transmit noise and vibrations into the cab. - John

-

Steering Issues/Cold Weather problems

This is just a personal opinion, but I think the power steering system on our generation of Dodge Rams is pushed to the limits from an engineering point of view. Years ago when I would design hydraulic systems for custom applications, I would always look at the maximum required force and maximum required speed of the system. I would then design the system to perform at 15% higher pressure and flow so that the system would never reach relief pressures or have the operation slow down under normal operating conditions. I don't think the engineers did that with our power steering systems. I think that the power steering pump is adequate for flow and pressure, but I think the steering gearbox is too light duty - mainly that the piston diameter is too small. Small piston area equates to a reduction of force with a specific pressure available (approximately 1500 psi maximum). Higher flow pumps do not help because it is the pressure that dictates the force (steering effort). I have 245 tires on my truck and a NAPA remanufactured power steering pump and a NAPA high ratio steering gearbox. When I am on a flat hard dry surface (concrete or asphalt) as I let the clutch out (slight drop in engine RPM) and turn away from a curb, I sometimes feel the power steering stall. It also did this when my truck was new with 265 tires and a slow ratio steering gearbox. Other than the noticeable brief stall under certain conditions, both pumps worked and work fine (the OEM I replaced at 215,000 miles although it was still working fine, and the NAPA one that am currently running). If the pump you received had the pressure relief valve set slightly low, the symptoms you describe would be logical. I don't think the quality control of setting / testing the relief valve pressure and setting /testing the flow control volume at a precise setting is there - especially with remanufactured pumps. - John

-

Left turn signal working wipers

@wil440, this is a very good example of why resistance checks using an ohmmeter and visual checks are not reliable for diagnosing electrical problems The ohmmeter just tells you there is a connection, but does not tell you anything about the quality of the connection - same with the visual check. I am glad you stayed with it and went back to the problem ground wire connection. - John

-

Battery Temp Sensor question

You guys and your popcorn...., - John

-

Battery Temp Sensor question

This is more very good information for diagnostics. This confirms that a large amount of current was flowing from the battery to the alternator. The glowing bolt confirms that the specific connection was a very poor connection - one with high resistance. The fuse did not blow because even though the current flow was high, it was still below the fuse rating. The rest of the wiring and connections were likely good because they did not get hot and handled the amperage load properly. This test has absolutely zero value for high current applications. Perform a simple test. Separate a single strand of wire from a 16 gauge mulit-strand wire. Cut the single strand wire to 12 inches in length. Test it with your ohmmeter - you will find that it reads zero ohms of resistance. Would you use that single strand wire for your charge wire? Keep the information coming. I would like to find out what exactly happened to your alternators. - John

-

Battery Temp Sensor question

@JAG1, this is very good detailed information which may help diagnose your failing alternators. I need to confirm - are you talking about the fuse you installed in the charge wire to the passenger side battery. I am assuming that you are. There is no mystery about the glowing bolt. The glowing bolt scene is telling you something very specific and emphasizes the importance of a good electrical connection. Just because a connector is tight does not mean the connector has a good electrical connection. This is also why I do not rely on physical inspections when it comes to wiring connections that handle high current loads - I perform voltage drop tests, but more about that later. They are easy to do and give you very accurate information about the condition of a connection. The only thing that can make that bolt glow is a poor connection at that exact location. The proof is that the fuse did not blow (because the current did not exceed its rating) and the other connector on the alternator side of the fuse holder was electrically sound. So, regardless of which way the current was flowing (charging current flowing to battery or battery current flowing to failed shorted alternator), the poor connection is a problem of its own and needs to be fixed. I still don't know what caused your alternator failures, but detailed observations like the one from you above should get us there. Can you describe the failed part or parts on each alternator? - John - John

-

Battery Temp Sensor question

Thank you for acknowledging and posting the fact that solenoids didn't fail in the closed position. I was having trouble understanding how a solenoid failing in the closed position would not discharge your batteries rapidly while the truck was shut off and to not see a low dash voltage gauge reading while the truck was running. So, is it correct to assume at this time that you have had two alternator failures with unknown causes? - John

-

volt gauge at 0

@dripley, this may be a place to start. This is the operational description of the voltage gauge from my 2002 repair manual. This may at least explain why your problem corrected itself for now. Hope this helps, - John Operation The voltage gauge gives an indication to the vehicle operator of the electrical system voltage. This gauge is controlled by the instrument cluster circuit board based upon the cluster programming and electronic messages received by the cluster from the Powertrain Control Module (PCM) over the Chrysler Collision Detection (CCD) data bus. The voltage gauge is an air core magnetic unit that receives battery current on the instrument cluster electronic circuit board through the fused ignition switch output (st-run) circuit whenever the ignition switch is in the On or Start positions. The cluster is programmed to move the gauge needle back to the low end of the scale after the ignition switch is turned to the Off position. The instrument cluster circuitry controls the gauge needle position and provides the following features: † Charge Fail Message - Each time the cluster receives a message from the PCM indicating a charge fail condition (system voltage is 10.8 volts or lower), the gauge needle is moved to the 8 volt graduation on the gauge scale and the check gauges indicator is illuminated. The gauge needle remains on the 8 volt graduation and the check gauges indicator remains illuminated until the cluster receives a message from the PCM indicating there is no charge fail condition (system voltage is 10.9 volts or higher, but lower than 16.7 volts), or until the ignition switch is turned to the Off position, whichever occurs first. On models equipped with the optional diesel engine, the instrument cluster is programmed to support the voltmeter gauge needle above the low end of normal graduation and suppress the check gauges indicator operation until ten seconds after the engine intake manifold air heater has completed its cycle.

-

Battery Temp Sensor question

Even if the output wire of the alternator is routed to the battery with the battery temperature sensor and that battery has a shorted cell, the battery temperature sensor will not stop the alternator from doing what it is commanded. From the example I gave previously: the shorted cell demands 50 amps (this time the driver side battery), the rest of the electrical system demands 25 amps (75 amps total). Let's say the battery temperature sensor tells the PCM to target for 13.8 volts. At the moment the alternator will be commanded by the electronic voltage regulator inside the PCM to reach the target voltage of 13.8 volts. To maintain that voltage, the alternator must keep delivering 75 amps. The battery temperature begins to rise (because of the shorted cell) so the battery temperature sensor sends this information to the PCM. The PCM decides to reduce target voltage to 13.5 volts, but nothing else has changed - the shorted cell still draws 50 amps and the remaining electrical load of 25 amps is still there, so the alternator continues to deliver 75 amps - 50 amps of unnecessary power to the shorted cell . This cycle will likely continue until the battery temperature sensor reaches its lower limits (which would have to be above battery static voltage), or the battery reaches a point that it can dissipate heat as rapidly as it is generating heat. But, meanwhile, the alternator will continue to do what it is commanded to do, and that is to deliver whatever amperage is needed to fulfill the target voltage. If the battery temperature sensor had the ability to limit target voltage to below normal battery static voltage, then many electronic components would be compromised - much more costly than an alternator. @Mopar1973Man, gives good examples of the benefits of performing equalizing charges on batteries to extend their life with his solar charging system for his house. But equalizing charges may not be as effective with some of our truck batteries. Not all batteries are equal when it comes to the quality of construction of the battery. Many times the failure of older batteries is simply the infrastructure supporting the cells fails and creates open or shorted circuits. Our trucks do not give batteries the smoothest ride. Good batteries and good electrical connections are key to long lasting alternators and electronic components. - John

-

Battery Temp Sensor question

I think that there is some misunderstanding regarding the purpose of the battery temperature sensor. The following is my understanding of how the charging system works: The battery temperature sensor is there to determine the target upper limit voltage of the charging system based on the temperature of the battery. By regulating the upper limit voltage (target voltage) at different values for different ambient temperatures, it gives a longer life span for the batteries. The battery temperature sensor does not control alternator output voltage at any time when the electrical load drops below the target voltage. Example: It's a hot day. The battery temperature sensor dictates target voltage to be 13.8 volts. @JAG1has wired his alternator output wire to the driver side battery because WT said so.... just kidding here. The passenger side battery has a shorted cell that is drawing 50 amps. The rest of the electrical load is 25 amps - a total of 75 amps. Charging voltage will fall below the targeted 13.8 volts and the internal voltage regulator in the PCM will tell the alternator to pick up the pace and put out whatever amperage is necessary to reach the target voltage of 13.8 volts. In this case the alternator will need to charge continuously at the 75 amp rate. So, moving the alternator output wire to the driver side battery does not help in this scenario. As @Mopar1973Man has said many times...., the batteries and electrical connections have to be in good operating condition so the charging system can operate properly. Demanding that the battery temperature sensor should be able to protect the alternator is akin to saying that the engine thermostat should be able to protect the engine when the radiator is plugged. or the water pump has stopped turning. - John

-

VP44 return line question

I think your return fuel back pressure concern is valid, but it may not be a problem at all. The real problem is that there is no place I know of to get the information as what is the maximum fuel return pressure allowed. I would give Blue Chip Diesel a call - they may have some information for you. Or, call a VP44 fuel injection pump rebuilder. - John

-

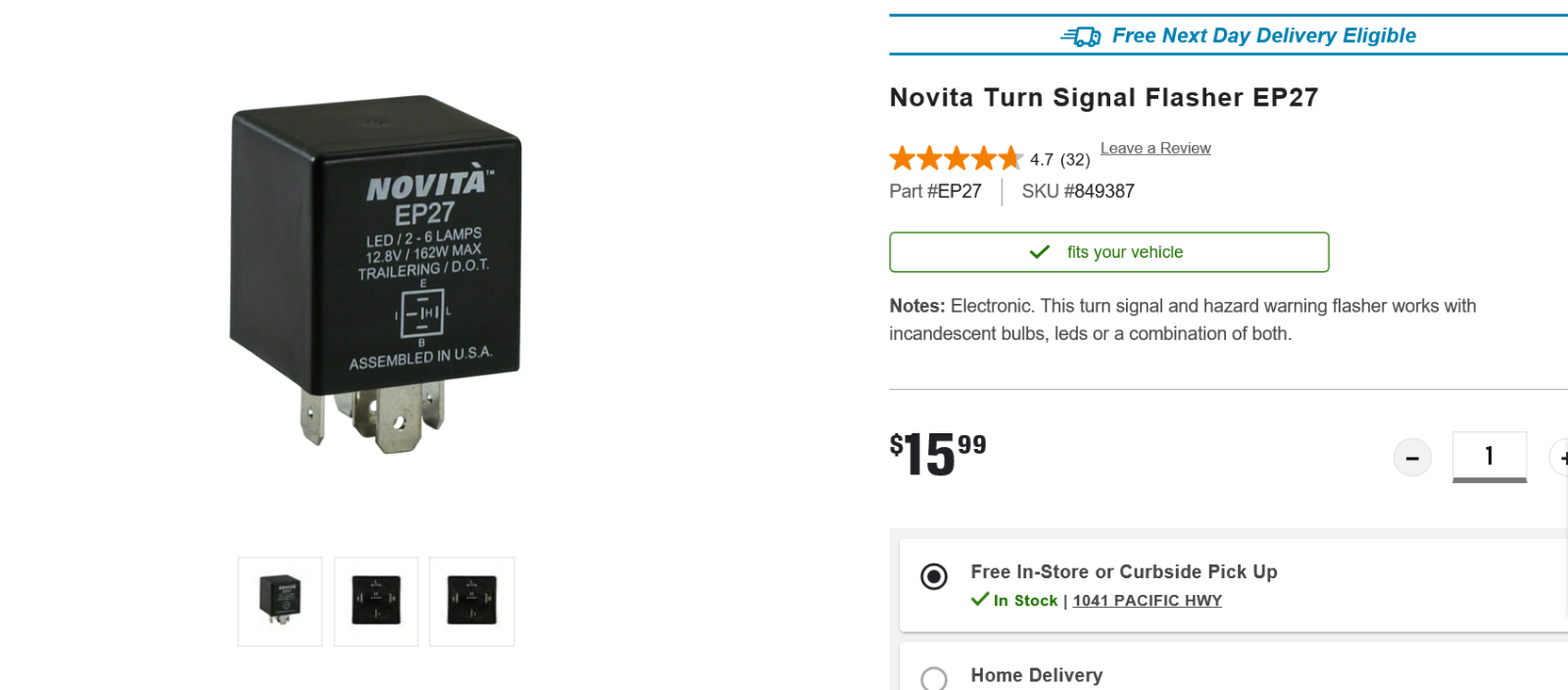

Blinker Relay

The OEM flasher requires a specific electrical to pass through the unit. The purpose is to let the driver know if a bulb is out (electrical load is reduced and flasher will flash rapidly) The heavy duty flasher requires a minimum electrical load. Even if one LED bulb is installed in the turn signal circuit, the reduced electrical load will cause the flasher to flash rapidly. The LED emergency hazard / turn signal flasher works properly with all incandescent bulb, all LED's, or a mix of both. I purchased the unit below at Autozone. The LED flasher sound level is slightly quieter than OEM and the cadence is slightly faster than OEM. I slowly switched over to all LED"s and the unit has performed flawlessly for over a year now. - John

-

Blinker Relay

Sanding the contacts may seem like a good idea, but there is a special coating of only a few 10,0000 of an inch thick on each contact that allows for the electrical cleaning of the contacts when the flasher operates. Sanding will remove that coating (which is probably gone already), so the fix will only be temporary. - John

-

No 4hi, only 4lo

I didn't know that, but it's a great idea! Would it be possible to post that information as a one liner at the top of the page for a few days so everyone would be able to see it? Something like, "Help Hint - Hover over any acronym with a dotted underline and view the meaning." - John

-

No 4hi, only 4lo

It is "center axle disconnect". I should have written the works and not assumed that everyone would know what CAD means. - John

-

No 4hi, only 4lo

You are experiencing an unusual symptom. I am assuming that you have a manual selector for the transfer case. To simplify troubleshooting, I would disconnect both vacuum lines from the CAD. Select 2 HIGH with the transfer case lever. Turn the engine off, set the park brake, and place the transmission in Park or 1st gear (if a manual). Go under the truck and ensure the front drive shaft rotates freely. This confirms that the CAD is disconnected. Select 4 HIGH and check front driveshaft rotation - it should be locked up. If it is not locked up, then you have a transfer case shifter issue or a problem inside the transfer case. If the front driveshaft is locked up, then you have a CAD mechanical problem or poor vacuum supply to the CAD vacuum motor. To check out the CAD operation I would use a vacuum pump and whatever suitable hose I had laying around to make up a temporary vacuum line that I could bring into the cab. I would hook one end of the line directly to the correct port on the CAD motor and leave the other port open for venting. I would connect the other end of the line inside the cab to the vacuum pump and operate the pump to at least 20" of vacuum. Verify the vacuum is holding and test 4 LOW and 4 HIGH operation. If the CAD works properly, then you have a vacuum supply problem. If the CAD doesn't work properly, then you have CAD mechanical problem. - John

-

Alternator quit...

@dave110, you are correct. I added my own momentary grid heater switch in the cab when my truck was new so I could be the boss of the grid heaters. Just the other morning it was 11° outside. I operated the grid heaters for about 15 to 20 seconds and started the engine - no post cycling to tax the alternator, so the batteries quickly recharged. No need to use the grid heaters for the rest of the day. A very inexpensive modification with great results - a win win situation. I am sure that the mod has added life to the alternator. - John

-

Alternator quit...

@Mopar1973Man, I think you must have had an off day. Even without the fuse modification in the circuit, I know you would have normally checked the field supply voltage to the alternator before condemning the alternator. I hope the Bosch alternator works out for you. I am still running the original Bosch alternator in my truck. - John

-

Intercooler Bypass

That is a great story! Some of the most embarrassing things we do are the best teachers! Once onboard my ship when I was in the Navy (back when I knew everything) I was assigned the task of filling a grease gun from a container of grease. Well, that should be simple enough. I removed the head of the grease gun, pulled out the plunger against its internal spring and hooked the T-handle under the edge of a workbench table top. I kept tension by holding the barrel upward with one hand while putting grease into the top of the barrel with the other hand. All was going well until the T-handle slipped and the top of the barrel came up and hit my chin. That hurt, but the event wasn't over. With the open end of the grease gun firmly imbedded into my chin, the grease discharged up past my mouth into my nose and filled the cavity between my glasses and my right eye. I froze while contemplating my situation, but I was even more focused on another thought..., did anyone see this happen? Fortunately for me, no one did. It took a long time to clean up the mess. I still had one problem; I was right back where I started - I needed to fill the grease gun. So, this time I studied the grease a bit and I noticed the lock tab to hold the plunger in place when it was pulled out. Things went better after that. When I returned to the group with a full grease gun, I was asked why it took so long. My answer was not truthful. - John

-

Intercooler Bypass

I knew someone might mention that because I thought of it myself, but I just couldn't resist. I apologize to any offended throttle bodies. - John

-

Intercooler Bypass

Yikes! Moving parts between the turbo and the engine? - John

-

First road trip in my 2nd Gen

How does that work if someone is stealing your truck? Do you tap on the window and ask the thief to reach in the back and hand you your high idle stick? I guess some thieves are more friendly than others, so it might work. I think a better anti-theft approach would an innovative security product using the "dead pedal" feature which is already standard on our trucks. - John

-

Red Head Steering Box

So, are you saying the redhead is a cheerleader? You may want to keep that quiet if your significant other is around. - John

-

Electrical questions/troubles

Not necessarily. I think that the predominant surrounding environment, the duty cycle of the truck, and the quality of the battery play a large role as well. I bought a 1991 Ford F150 4x4 truck new and immediately installed a Cummins 4BTA 3.9 liter engine. The OEM external voltage regulator was located in the right side fender well. After five years of driving in the vicinity of Leadville, Colorado (10,200 ft elevation) and four years of driving in Redding, California (100° everyday throughout the summer), the single battery was still passing load tests after 9 years and over 200,000 miles of operation. I like the idea of a temperature sensor under the battery to increase battery life, but if the PCM on my truck fails to charge the batteries properly, I will more than likely switch to an external voltage regulator. . On my current truck the OEM batteries lasted for 10 years (178,000 miles). The second set lasted 6 years (115,000 miles). The current set (Group 24's) have been in use for 3 1/2 years (about 45,000 miles). I think my OEM batteries were the best quality. - John