Everything posted by ISX

-

What The Heck???

Go to that site, log out, then come here and click on that link. Because we are not members there, we cannot see anything, it takes us straight to their log in page.

-

What The Heck???

...which means, jokes on you

-

Back at it again...

More like every time I go to the bathroom. How you know anything about it though.......along with all the other things you seem to know about..teach me a little more about you

-

Back at it again...

Yeah it was, even still it had a big bend on the handle. I assume a breaker bar in conjunction with the fork truck did that. Kinda weird how I work, something like that for pipe yet I take my whole truck apart with a 1/4" socket set

-

Back at it again...

Get back to work! I just put in 25 hours saturday/sunday. Welfare is starting to look pretty appealing There is a trick to it though. As you get more wore out/sore, leverage is key. We did a whole bunch of pipe fitting and by the end of the day I was using a 4ft pipe wrench to tighten 1/2" lines lol. I didn't see the need to tighten real good with a small wrench when I could just let the big one drop, tightening it without any effort from me.

-

I think I may have the job I actually want finally

They want me to come in for another interview with different people. I've never had 2 interviews with the same company so I guess they really want to make sure they get the right person. I just have to figure out how to sneak away from my current job to go down there.

-

Power Outage...

I see a lot of benefits to a power outage. I go ride every weekend so I basically am without power every weekend. [*]Your drinks in ice cold water are a heck of a lot better than the fridge. [*]BBQ ribs, hot dogs, etc for dinner over the fire. [*]Smores [*]If you hit the right time of the year, the temperature and slight wind are 10x better than your homes hvac. [*]Taking a leak only requires you to stand up. [*]Your hearing starts to get better as you spend more time away from factories. Ok I guess that was benefits of camping. Either way I hate living in the house, all I want is my phone since it has internet on it, besides that I would rather be camping on the shore of a lake.

-

State Police

I wouldn't tolerate any excuse either. How hard is it to glance down at a speedometer.. I would give a big ticket for the speedometer gear excuse because you obviously knew it was off since you used it as an excuse and didn't care to drive 5mph slower. I realize cops are suckers for good excuses but from what I have seen, all they want is respect. Every time I have gotten pulled over (3 times) I have gotten off the road and pulled into a parking lot. This means they don't have to worry about traffic at all. So far, it has worked like a charm, even getting me out of a C&I. I never give them an excuse. The C&I woulda been for pulling out of a parking lot and flooring it until I was 15 over the limit, blacking out all the lanes. He asked what my hurry was and I just told him you know how it is.. He said I should know better and let me off. If you give them excuses you are basically testing to see how stupid they are. Most will catch on and then you wonder why you have a big ticket to pay. I'm not trying to call you out on all this, just saying my take on cops.

-

Egt temp

I haven't even posted in this thread Nevertheless, I will pass someone and turn a blind eye to it, but the more I tinker with the truck the more I realize that 1200 IS a possible limit while still having the same amount of passing power. I have a very hard time going over 1200 even with the trailer and passing someone. I have pulled it 1000 miles and passed several people on 2 lane roads and the highest I have seen is 1235. Raising the RPM's and lower the MPH is key. If your over 1200, then your RPM:MPH ratio is off, raise the RPM and lower the speed..

-

I think I may have the job I actually want finally

This might be the best thing ever. They told me that they just bought this company that installs these 3 cylinder kubotas on the semi trucks and apparently they have absolute no documentation on how to do it. They seem lost or something. Something like that intrigues me like no other and I want to do it so bad. They said if I can figure it out I would have to teach all these people in other states as well. I had already read the manual on it which was pretty sketchy but it's easy enough. A computer controls everything so I'm not exactly sure what the problem is. I can run a mill and lathe and all kinds of crap so it's not like I can't make anything work. I don't have to work weekends and I will live at the place I ride at so it couldn't be better. I couldn't tell if they had any other people they interviewed or not, I tried to make it as obvious as possible that there wasn't a single thing I hadn't touched on a diesel. We shall see.

-

Passing Lane Boost

I saw this while looking at B47 stuff. Called JATO (jet assisted take off) or more recently RATO (rocket assisted take off). From what I found out, when planes are heavily loaded and have short runways or are taking off in a hot and high elevation, they use these to give them an extra kick in the rear. I thought it was absolutely incredible. http-~~-//www.youtube.com/watch?v=Nw2bAJGgCZI&feature=related Then theres this thing which is just nuts. http-~~-//www.youtube.com/watch?NR=1&v=WKCl3lfAx1Q Heres a pic of a B47 using them. --- Update to the previous post... Just found this, my new boat. http-~~-//www.youtube.com/watch?v=WlEt0bCeTy8&feature=related

-

I think I may have the job I actually want finally

Yeah, cept my shoulder is permanently lower than the other one. Insurance company seems to be playing games with me now, got a bill yesterday for $1100 because I quit my last job which I had insurance through them with. Says that since I quit I get no benefits, even though I worked there another month after the accident. I have already spent $2000 on parts to fix the bike and doctors bills so another 1100 would make it a $3100 accident. I just don't get how they can say I owe them since I quit. It wasn't technically a bill yet but more of a prerequisite for a bill to come, like a warning that I better not spend any money. The due date is always within a few days of getting the bill. The bad part is, they didn't do anything. I went in to the ER, they said don't move it, then I went to a specialist and he said only move it if it doesn't hurt. It never hurt so basically I didn't do anything different, other than I had no ability to lift anything with that arm so that limited it, I still can't do a pushup without it feeling a little interesting, oddly I can do pullups just fine, though I know pushups pretty well target the shoulder so explain why it doesn't like it. I am a pro at this interview crap after a million jobs. Walk in, tell them what they want to hear and leave

-

Ditching the overloads for airbags, maybe, need input..

This is getting tough, so many options. I really like the idea of airbags since they are always contacting. Oversized rubber things is something to think about but I don't want to have a haywagon ride the entire time. Timbrens are nice but I don't like that the don't contact when they aren't in use. I will hardly use any type of "overload" so I don't think air bags will really screw with the truck too much, I just need a few pounds in them to help it out a little. I do like the other options but I just can't convince myself to get them after listening to this thing for months. Now the question is, which airbags are best? I don't need anything but the bags and maybe the mounts, I can air them up under the truck or run air lines to the back bumper or something.

-

I think I may have the job I actually want finally

As you guys know (or may not have known) I ride dirt bikes a LOT. Mainly in springfield, MO. Last week I wondered why I was driving 300 miles a weekend just to go riding, so I looked at the jobs there and found one for APU tech. An APU is an auxilliary power unit. It is a 20hp diesel, thinking 2 or 3 cylinder, that runs the heat, a/c, alternator, etc for a trucker instead of otherwise running his 14 liter engine all night just to keep warm. They are a neat little engine and I think it would be really nice to work on them, wouldn't have to have a cherry picker just to take the head off. I have always wanted to mess with diesels as my job and I went to school for generators anyway so this takes the cake. Interview is monday.Bad part is I have only been with the current job for a month lol. To me, there is no reason you should have to stay at the same job just to show you got what it takes to stick with a job, or make the boss happy. He has tons of money so of course he's happy, mine has a brand new duramax so I know he's fine and dandy. You should always do what makes YOU happy, and I want to be in the position of living on my own and having a job I like. I still live at home because I never saw myself as one that would want to live around here, I always wanted to live somewhere else and right next to my dirt bike area would be heaven. I'm pretty sure I'll get the job, just need to find out the finer details.

-

How I should I add my Pressure Gauge and beyond

It would be a lot better having mechanical gauges. My stupid oil pressure gauge keeps flickering between pressure and no pressure, like there are air bubbles in the system. I can check the oil and its fine. A mechanical gauge would tell me for sure as the OEM is just a POS indicator basically. The RPM is another thing. The OEM gauge is worthless and should only be used to getting within 25-50RPM. I noticed on the 24V's the RPM on the edge or scangauge varies like 5RPM, making me think the sensor isn't the best. The RPM gauge I got is digital and you put a magnet on the damper for it to pick up signal, I put 4 on it equally spaced to get a damn accurate reading and the RPM at idle is rock solid, not this 5RPM varying crap. If the engine gets a degree warmer, the rpm goes up accordingly with the reduced friction. I can see everything, even rolling up the windows can be seen as a few rpm drop. If I had it my way I would get rid of every sweeping gauge in place of a digital one, which I am slowly doing. Airplanes know how far they have left to fly very accurately, they would be screwed with the gauges in these trucks and it drives me nuts not knowing something very accurately. I would really like to know my exact speed down to one decimal place but GPS takes too long to refresh speeds and I don't know if there is something out there that accurate that doesn't use GPS.

-

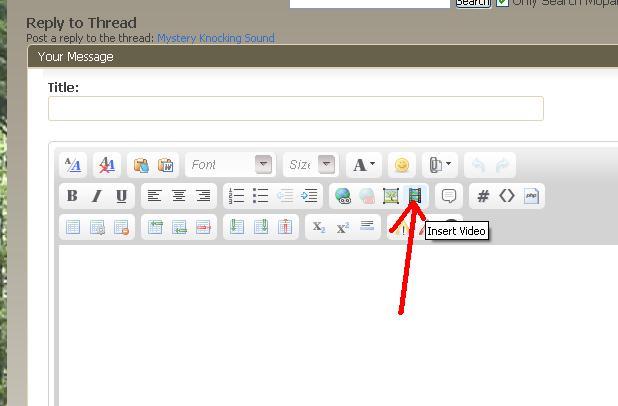

Mystery Knocking Sound

So it does it regardless of clutch engagement or whether or not you are moving, correct?That leaves just the engine which I am gonna have to list everything out that moves and think of how to pinpoint it.Pistons/Conrods-Too FastCrankshaft-Too FastCamshaft-Too FastTappets-Too FastPushrods-Too FastRockers-Too FastValves-Too FastOil Pump-Doubt itWater Pump-Possibility but too fastAlternator-Too FastVacuum Pump-PossibilityPower Steering Pump-PossibilityFan-Likely Possibility, is it whacking something?Belt-MaybeA/C Compressor-Too FastP7100:Plungers, Delivery Valves, Cam, Governor, Rack-All Too Fast, and rack won't do that anywaysInjectors-Too FastStarter-Not involved, and flywheel moving too fast (if it was nicking starter gear somehow)Flywheel-Too FastTurbo-Way too FastLift Pump-Possibility, but changed out with no luckThermostat-Highly Doubt itI need to think about it more. I think some things could still cause a slow knock at idle, even if they are moving fast.

-

Mystery Knocking Sound

-

Mystery Knocking Sound

The problem is that, that knock is so slow it just can't be any of those things. I can think of something that builds over time and then relieves as a knock but I just can't think of what would do something like that. As heat builds things expand so the thing knocking could be loosening up, when it's cold everything is tight so it knocks more.

-

Mystery Knocking Sound

During the last 2 seconds was it the knocking that happened just short of every second? I didn't realize the knock was that slow if that indeed was the knock. The problem I see with that is that it eliminates a lot of things on the engine. Each injector fires 6.25 times a second at 750RPM (since you were idling that's what I used). The valves open just as many times as well. Lift pump does as well. The only thing that is that slow that I can think of is the overflow valve popping, but I wouldn't think it would make that much noise being just a ball on top of a spring. I'll keep thinking.

-

Mystery Knocking Sound

A video of this sound would really help but I know the noise probably won't be audible in the video. I will say that mine has something of this nature as well, doing the same as you describe. Mine isnt a knocking but more of a well maybe it is, just seems faint and almost muffled. I took my intake manifold plate thing off and stuck a light in the valve ports and there was a lot of crap in there, varying between each one, a lot. I am thinking the crap around the valves has something to do with it. I have seen 1600 as well.. Truck runs same as yours too so it really is weird. Pretty sure it just has to be something with the valves. Don't want to fork $100 for a head gasket yet.

-

P7100 pump removal

If you need more help my phone number is on my profile on here.. That thing comes out pretty easy but I know theres some things that might hang you up or you just might have a question on. If you're good it can be taken out in 45 min, supposedly. Think I pulled it off in 4 hours doing my usual starring and taking breaks and pre/post breaks. Still, if you need more vids, anything, just let me know and I'll get it. I'll take the thing out again if need be.

-

Ditching the overloads for airbags, maybe, need input..

My truck used to basically do what Caj does, cept with campers for 200k miles.. So I'm guessing these springs have lost their sprung a little. I could get new springs but I'm still going to face the problem down the road so would rather ditch those damn overloads, plus worn out springs give it a better ride, but I need something to handle the extra weight of the trailer/firewood/stuff that weighs down the bed. There isn't enough wood to amount to much weight, think the problem is more that the divets here are really deep and it's like your going over train tracks. If I don't go 5mph over railroad crossings it does it like crazy. I'll have to make a video of it tomorrow.

-

P7100 pump removal

Just did this a few weekends ago. Take fuel lines off (injector lines, supply line, return line) Take throttle cables off Unplug shutoff solenoid Take off oil line Pin the pump timing (after you have broken the nut on the timing gear loose, otherwise the slight play when breaking the nut loose will break the plastic on the pin) Pop timing gear off with gear pulled Take fuel filter housing out so you have room to pull the pump back Take 1 mounting bolt out of the bottom of the pump Take the other 3 or 4 bolts out of the timing case Think thats it, just pull kinda hard because it has a seal in the case, not overly hard just enough to pop it out, its rubber so if you're taking the crowbar to it you might have forgot a bolt. I got a million pictures so give me some time and I'll throw a how to together as fast as I can right now, have it done in an hour or 2. --- Update to the previous post... Alright I apparently have a million videos of things more in depth about the pump than the actual taking off the truck part. I ran out and just made another video. Hope it isn't too crappy, made it with my phone since camera is dead. I know its all over the place on lighting but I hope it helps you. If you could tell me which things are holding you up I could go into a lot of detail about them with a lot more pics (in the daylight tomorrow, maybe even in the early morning before work). Here is a link about timing and the timing pin I am talking about. http://mopar.mopar1973man.com/cummins/2ndgen12v/p-pump/timing-check.htm Here is the crappy vid. http-~~-//www.youtube.com/watch?v=6og_1I-0cbM

-

Ditching the overloads for airbags, maybe, need input..

The only thing I'm not sure about is that it seems when you have a light load, it lets off the timbrens completely, like my overloads are off completely right now, but when I hit a hole in the road they slam, just like it seems the timbrens would do. After all, the timbrens would be rubber to a steel (axle) contact, same as the overloads (steel) are hitting the stops which are rubber.. Air bags woulnd't have that since they don't exactly stop contacting if they are not being used. I'd like to find more out on the timbrens though, but I'd hate to get them just to have the same problem.

-

Ditching the overloads for airbags, maybe, need input..

My bed has firewood in it, not much but my regular springs are a little weak and when I hit big divets in the road the suspension slams the overloads up into the rubber things that the overloads touch when being used, it sounds like the tailgate fell off when it does it. The plan/theory is that by ditching the overloads and replacing them with air bags that it will solve the issue. I could care less about anything fancy, I don't care if I have to get under the bed and air them up by hand. I hate those overloads and always have. Any ideas on where to get the bags and which ones to get? Cheaper the better but I'd rather it be cheap because I air them up by hand rather than cheaply made, I'll pay anything for something quality made (NOT CHINESE!)Also, if you have another solution I would love to hear it. No I'm not taking the firewood out of the bed