-

1999 Dodge lift pump

I would see if I could find someone that has the in tank pump and measure their amp draw so you would have an apples to apples comparison but if a Fass (with a much bigger pump) is only pulling .5 amps than I would be suspicious of the little in tank pulling three times as many.

-

Which I50 Amp Circuit Breaker

bussman from Amazon. Just over 3 years and no issues so far. https://www.amazon.com/gp/product/B01G5WHP2M/ref=ppx_yo_dt_b_search_asin_title?ie=UTF8&psc=1

-

Valve Lash Adjustment Question

Thanks John. Sorry for the confusion, I should of worded my initial post better. I feel better now.

-

Valve Lash Adjustment Question

I used @Mopar1973Man procedure in the articles section, same one that I used the last time. It references spinning the engine till you see BDC for the VP44 gear.

-

Valve Lash Adjustment Question

I did my valve lash yesterday while doing an oil change. This is the second time doing the procedure. I put the engine at TDC and did my adjustments, adjusting all the valves that were loose and that I could jiggle. I put the engine at BDC and started on the next set. While doing these I looked up the procedure on here to find out what the torque setting was for the jamb nuts and I noticed that one of the valves was loose (I could jiggle it) that wasn't on the list of valves to adjust while at BDC. I finished up adjusting the valves that should of been adjusted and rotated the engine back to TDC and checked the valves and there was one that was loose that shouldn't be adjusted. My question, is this normal. I dont remember the last time having any loose that shouldn't be but I'm pretty sure I just followed the procedure and didn't bother checking valves that weren't listed. So at TDC I had a exhaust valve in bank 2 that was loose that shouldn't be and at BDC there was an exhaust valve in bank 5. Is this normal and if not how do I remedy it? BTW... the engine is not any noisier and if anything its less clacky after doing the adjustment (I had some that I must of not set correctly last time).

-

MAP sensor again or so I thought

-

Shock! Unknown order coming?

-

Shock! Unknown order coming?

Yeah, I hate how I cant use all the display boxes on my phone because they overlap.

-

W T mod ciruit breaker

This is the breaker that I used. I have never had it pop yet. https://www.amazon.com/gp/product/B01G5WHP2M/ref=ppx_yo_dt_b_search_asin_title?ie=UTF8&psc=1

-

Dreaded No Bus and everything that goes with it

I just did the PCM grounds on my truck a few weeks ago as i was having an issue with my torque converter not unlocking when letting off the gas pedal. I will tell you when I finished and got in the truck to fire it up and back it out of the garage I had the "no buss" on the cluster. I went and checked my connections and somehow I didnt get a good crimp/solder and one of grounds pulled out. I fixed that and everything was good. No more torque converter issues either. Fixing those grounds is no joke!

-

98.5 crank no start

He just got his PCM and ECM back from them

-

98.5 crank no start

That sounds about par for the course for Autozone

-

Ball joints and Control Arms, Suspension in general

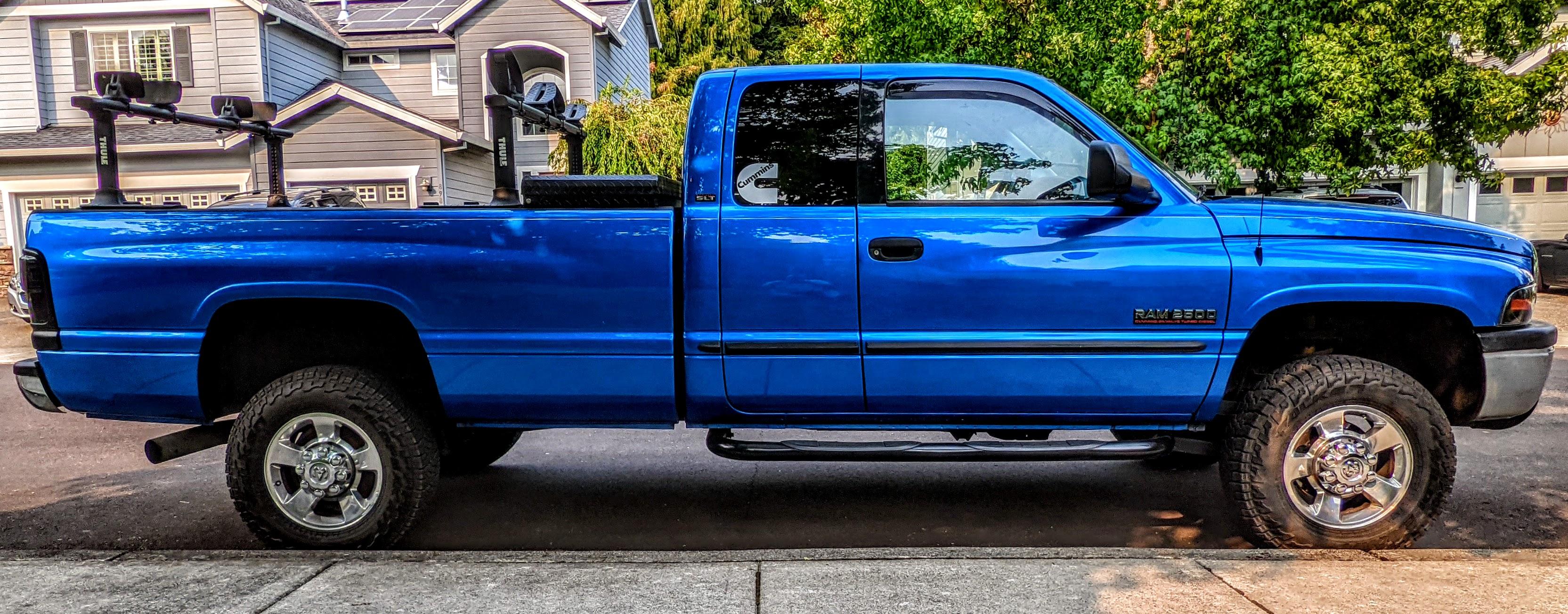

control arms run from the axle to the frame one on the upper side of the axle and one on the lower side. These are both on the left and right side. In the picture below you can see a stock control arm in the upper position and an adjustable one in the lower.

-

98.5 crank no start

We were talking about the crank sensor

-

98.5 crank no start

mine came with the metal piece on it