Everything posted by IBMobile

-

Fried ECM from lift pump wiring? Also ECM pin 44?

That wouldn't do it. The power to the fuel pump would be battery/PDC fuse, to relay terminal 30, to relay terminal 87, to fuel pump. In a proper installation the fuse would blow. The ECM powers relay terminal 86 to the relay solenoid. The power draw on the ECM would be .175 amps at 14V. They are resistor protected.

-

Merry Christmas

- 1998.5 SLT Laramie power seats HELP!

I think this is the wire diagram that will work for you. To test a motor apply 12 volts to one wire going to a motor and a ground to the other wire. To test the driver power seat horizontal motor apply 12 volts to pin p17 red/light blue wire (not the red/light blue wire from the circuit breaker) and ground pin p15 yellow/light blue wire; the motor should move one way. reversing the power and ground will make the reverse. The other motors can be tested the same way by applying power and ground to them.- Radiator failure

From the FSM "STANDARD PROCEDURE—COOLANT SELECTION-ADDITIVES The presence of aluminum components in the cooling system requires strict corrosion protection. Maintain coolant at specified level with a mixture of ethylene glycol based antifreeze and water. If coolant becomes contaminated or looses color, drain and flush cooling system and fill with correctly mixed solution." So, the factory calls for ethylene glycol, the green stuff, which has anticorrosive phosphates and silicates. This type of antifreeze calls for a flush and change every 30,000-36,000 miles or 24-36 months. The FSM calls for the first coolant flush and change at 52,500miles or 42 months which is to long a time and the Ph level can fall well below 8.0. This is one of many articles I found on engine antifreeze. https://www.hemmings.com/blog/2014/08/01/tech-101-the-colors-of-antifreeze/- 1998.5 SLT Laramie power seats HELP!

All the diagrams show the power to the seats at the red/light blue wire. I don't see any pink wire in the seat diagrams. Are these seats out of a standard cab or a club cab?- 1998.5 SLT Laramie power seats HELP!

May be these diagrams will help. They are for a 99. The power seats are in them.- Radiator failure

Walmart https://www.walmart.com/ip/Super-Tech-Antifreeze-Coolant/16645420- Need help P0222 P1690 P0336

Please fill out your signature so we can better help: what year, model, transmission, any modifications. You need to do some diagnostic work. Since more problems manifested after moving the wire harness you my want to start by checking if there are any shorts or open circuits in it. How many miles on the truck? P codes 1000 or higher are manufacture vehicle specific.- Crazy life - Just blogging

Just did this last week on shower/tub fixture that was dripping. I thought it was a Delta faucet but when the Home Depot associate saw the part he knew it was a Price Pfister. Took the old part out, new part in, fixed, saved a bunch of money.- Fried ECM from lift pump wiring? Also ECM pin 44?

Data link shielding is usually a braded cable around a wire or wire bundle. It is uses to keep stray electromagnetic from interfering with a low voltage signal. it acts like a Faraday cage. Sometimes the specs call for the ends to be grounded.- 2002 Dodge Ram 3500 dead pedal

I have one as a spare under my back seat.- You Folks Have Your Firewood In?

Some places you can't. It's BTU rating is just below oak. The tree is an invasive species. It is a fast growing tree brought here from Australia by the rail road to make ties from it. They found that it was not good for that because as the tree grows the trunk twists. I don't know how the free range chickens will win; looking at that would kill any pecker.- You Folks Have Your Firewood In?

I finally got firewood for my wife's winter ambiance. My son and a worker went and got 4 truck loads of eucalyptus that the utility company cut so it wouldn't touch their high voltage lines. Two loads were cut last week and two loads were from 2 years ago so that will be ready to burn. Now all I have to do it get the grandkids over here to help split it. Another 2000 24 valve pulled up to get the free wood. My truck is on the left. My son Web (on the left) with Raphael unloading.- 47re

- overdrive and tcc solenoid 47re removal without valve body drop?

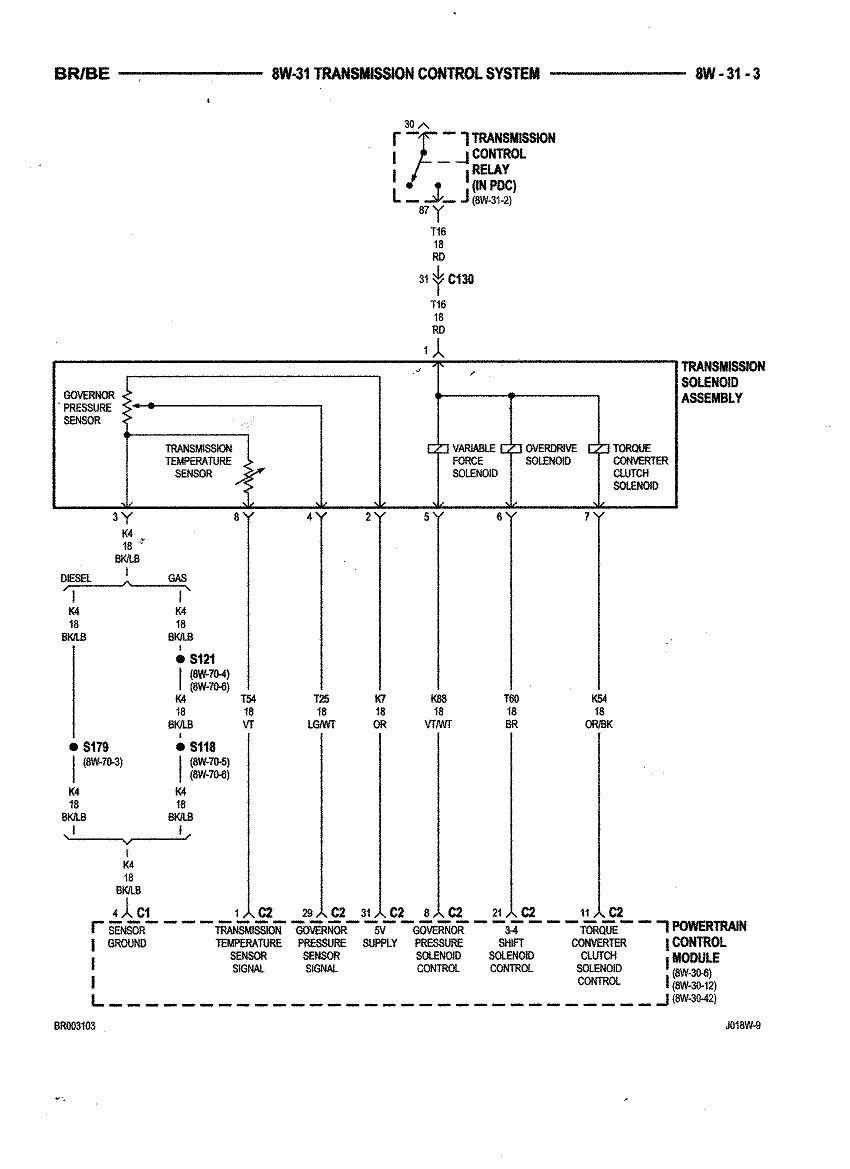

I've replaced the solenoids without removing the valve body. Unplug the electrical connector at the left side of the transmission and clean the area around it Remove the oil pan and filter. Remove the governor solenoid and transducer. Remove the 3 screws holing the overdrive/TCC solenoids. Now watch this video on removing the 3-4 accumulator housing; the top of the accumulator is where the wire connector is attached. The screw that attaches it is different than the others, don't mix them up. https://www.youtube.com/watch?v=D-ctMbta0-I The O-rings on the connector should be lubed so it will slid into the case and not be damaged. Install the 3-4 accumulator per the video. Now install the new OD/TCC solenoids then the governor and transducer and plugin them into the wire harness.. install new filter then pan with gasket. The torque on the T-25 screws is 30 IN-LB and pan bolt is 10 FT-LB. If you can let the truck sit over night so fluid can drain down before taking the pan off. You'll get more fluid out that way.- Clear Coat rash is spreading

What number grit sandpaper and what is the solution?- 47re

Is the shift solenoid the same as the governor solenoid? Have you ohm tested the solenoid to see if there is a short?- Waste gate actuator preload

You probably have some debris stuck in the fuel pressure relief valve holding it open. You will have to take it off and clean it out. This is a common problem when the Fuel Boss system is first used and it happened to mine and others here. You my want to install a 120 micron prefilter before the pump.- Replacement Battery Recommendation

- Replacement Battery Recommendation

Me too.- Factory alarm question

You're right, there should be a way to keep the horn option for the alarm. Putting a switch in the black/red wire and running it up to some place on the dash would work. This would create an open/closed circuit between ,the horn relay and the central timer.- Replacement Battery Recommendation

Thinking of selling...Go with 3 year warranty inexpensive batteries. If you sell the truck you've saved some money If you still have the truck after the 3+ years replace them again with 3 year batteries, you'll probably sell it by then.- power/fuel loss - dead pedal? seeking advice.

When sitting in the driver's seat it would be In front of your left foot but on the outside of the firewall.- Front hub extension and wheel bearing TRQ specs (2wd 3500)

2 wheel drive front Hub Bearing HD2500/3500 Nut 280 Ft Lbs.- Factory alarm question

No, it's like what you've done to silence the alarm sounding the horn; this is just another work around. I think the only way to fix this horn problem, if the foil wrap doesn't work, is to replace the central timer module. - 1998.5 SLT Laramie power seats HELP!