Everything posted by Haggar

-

Lost power

I have noticed two areas that can easily cause a loss of prime, causing a long crank cycle. The first is the seals on the banjo bolt on the back of the head. Its a pita (especially with my elephant arms and hands.) The other (and the easiest to check) if you still have the stock quick connect from the pump to the inlet of the fuel manager. This O-ring is awful. It will not leak under pressure, but will under vacuum..... so the fuel runs back to the tank.... try a glob of grease on the nipple and see if the problem goes away for a few days. For me those just cause long cranks. I run fine after it starts (no power loss) but my pressure stays up. It looks like you may have a combination problem (leak and pump) Otherwise.... its all the things Mike pointed out. Hope you find it!!!! GL HTH Hag

-

Weird issue with brake pedal feel and PS pump

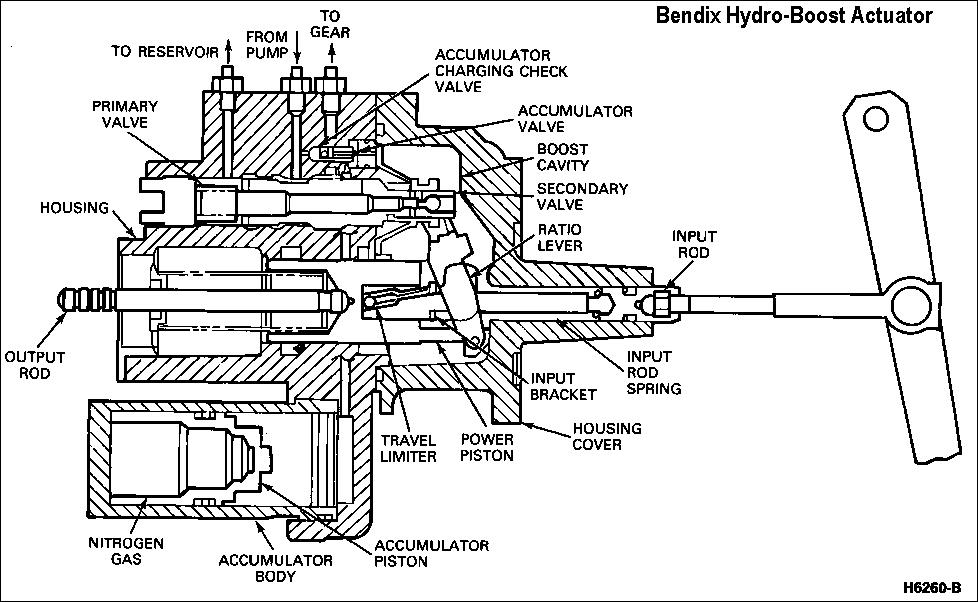

Katoom, Here is the cross section. The first movement is the brake pedal on the rod and taking up slack in the input rod. You then start pushing the power piston (and output rod of the hydro) as the input rod/power piston is moving, the linkage to the primary valve is moving to apply pressure. So there is a lot going on in that first little bit of movement. Take things apart slowly and keep checking where your stickyness is. You may be able to follow it to the exact piece that is hanging a bit. Move master cylinder away first and check. Disconnect input rod and check your pedal movement etc. GL HTH Hag

-

4X4 bearing Hubs and ABS Discussion....

Jag, I know I can't sway you, you just experienced something that I hope I never do. (I am so glad you guys are OK.) Do NOT buy the hubs because you are going to see a mileage increase. (I want to see actual numbers... engineering calculations of the inertial loads and oil drags of the components still turning. I could run them, but am too busy right now.) Lets think through it. With our central axle disconnect what turns when we unlock? On the passenger side a very small stub shaft. On the driver side, again a stub shaft and the spiders in the carrier. The ring and pinion do no turn. The front propeller shaft does not turn. The drag from the inertial mass of these items is totally lost in comparison of turning our wheels and rear differential (especially those of us with a locker). The design of our tires (and pressures) would have a much more significant impact on mileage. Heck our frontal area alone.... or at least our height above the road..... You want a piece of mind. There is no price on that. Don't justify it otherwise. You will be disappointed if you do. I truly doubt that you will see a savings in mileage. (I hope you do!!! Just don't buy them thinking they will pay for themselves....) Anecdotally, With the EPA so harsh on milage of new vehicles, what manufacturer installs manual locking hubs? (I agree manual hubs don't work well with "auto 4x4 and all wheel drive type situations") but on their base models, who uses them? Now I agree, not everything on new vehicles is mileage based, ease of assembly, cost and getting through warranty period is high on the list but none that I can think of come with manual hubs anymore. ymmv, HTH Hag

-

Anyone rebuild their hydroboost unit?

Drip, Thanks for the update.... I didn't know if the Dodge units were staked or not. That does make it a bit more of a hassle, but not the end of the world. Hag

-

Weird issue with brake pedal feel and PS pump

K, Yes. It is not hard. Send me a pm. I can help walk you through it. Hag

-

Anyone rebuild their hydroboost unit?

Its crazy, but the only thing that can be "hard" is if the brake pedal rod is staked to the input of the hydroboost. Otherwise it is super straight forward. Keep in mind, the one I rebuilt was from a GM truck (same hydroboost unit) The input rod was staked (not all years of GM were staked, many had an adjustable rod). I am not sure whether the Dodge units are staked or not. The FSM is no help, as hydroboost repair was not a dealership level operation. You replace it as a unit. If you buy a replacement, make sure, before you install it, that the brake pedal rod is the same length as the one you are replacing!!!! this is about the only difference between the hydroboosts. (the other is the color of the accumulator. This designates the precharge pressure. I have yet to see much of a difference, but I image it has to do with the number of brake pedal applies of boosted brakes with the engine off balanced against the operational pressure of the power steering pump.) GL , HTH Hag

-

Weird issue with brake pedal feel and PS pump

K, Here is a good article on the hydroboost. http://www.brakeandfrontend.com/operation-diagnosis-and-repair-of-hydro-boost-power-assist-systems/ Here are the quick test procedures. It sounds like your accumulator is bad for certain, and maybe another seal or two.

-

torque converter lock up install

You need to be careful with that type of switch. The internal circuitry has a "ground" in it. (Has to do with the board for the LED lights.) this could confuse your sense to ground for the TC. If you must have a light, you need to use a double pole switch. This will allow you to have two completely separate circuits in the same switch. One will only hook to your TC circuit. The other pole will be used to switch on and off a light. HTH Hag

-

Hydroboost now brake pedal stuck to floor

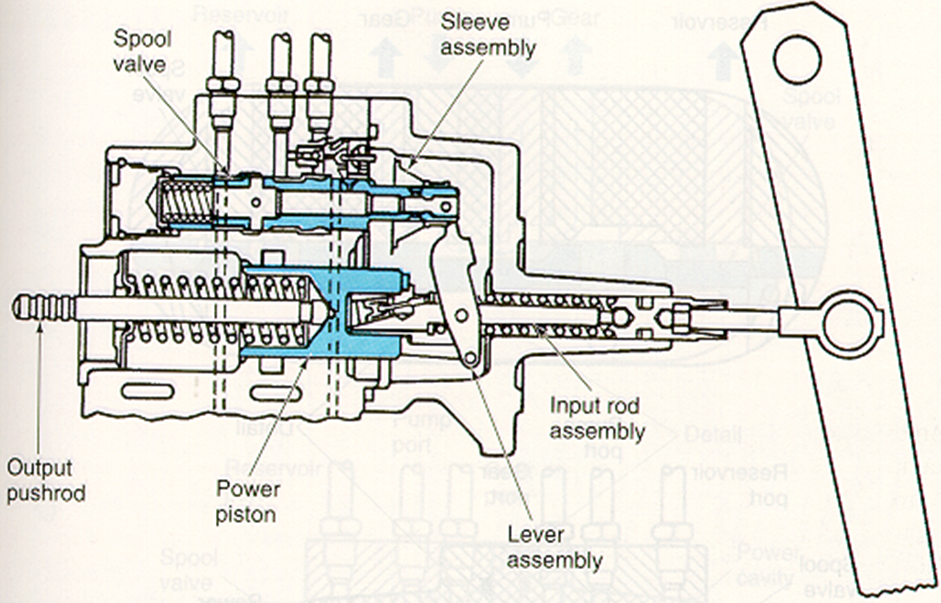

Sean, You re-assembled something backwards, the seals got in the wrong place, or the rod coupling didn't seat. I think you can get the "lever assebly" in backwards or out of place. This will hold the spool valve in just the right spot that during start up, it thinks you have your foot on the pedal. Another possibility, is the ball at the end of the rod from the brake did not get into the coupling correctly. So it is too long and thinks you are pressing on it. Its up to you and where you think the mistake may be. You could take the rod out of the brake pedal. If the truck works normally, it is the coupling or the rod. If it is still applying the brakes, it is the position of the spool valve. HTH Hag

-

Locker or Limited Slip?

I am not near my truck. IIRC the code for limited slip was DSA. I am not seeing that on your sheet. I am seeing everything in the world for spline count. (except the 37 lol) So far, I think the 70-2U was 32 spline, but so many people dump all the 70's in one lump or only the 70b and 70u.... But a nice write up on pirate 4x4 on the dana leads me this way. I cannot confirm the count through the factory parts list. The part number for the 70-2u axle is 0474662. I can only find stock descriptions for that part.... While the eaton power lock is not available apparently in the 32, new axle shafts are only about 200 each in chrome moly (less in regular alloy (one possibility). The other possibility is detroit lockers and dana units are available brand new in many more spline configurations. It looks like you have a totally open carrier right now, so any of the above ideas are a killer step forward. GL HTH Hag

-

Locker or Limited Slip?

Your existing rear differential could be a limited slip. Most likely the clutches are just worn. Just replacing those and a re-stack (depending on which axle you have) should bring the rear axle back into mostly positive traction. (automatic 2500's got the dana 70u and manual trucks got the dana 80. not enough information in your signature or description to tell which you have.) If no one has lost it, there should be a tag under a diff cover bolt telling you to add limited slip additive. The front axle has a couple different possibilities with different pros and cons associated to each method. Air locking is the best of all worlds, just very spendy. Are you sure your front axle is working? Reason I ask, I will spin in wet grass in 2wd. When I put her in 4 I never have been stuck. (knocks on wood) (I have vultures circling, just waiting to hook me to the sucker end of a tow strap!) I don't have the snow and such you have, but when we do, the weight on the front axle is all I have needed so far even though the front diff is open. HTH Hag

-

Aaxle slop

Scott, The Dana 70 and 80s do not use a crush sleeve to maintain a preload on the pinion. Part of the initial set up for the pinion (you will read it in there) is finding the point of shims that there is zero axial movement of the pinion. From this point you will remove a set amount of shims to set the initial preload of the pinion. Your carrier fell out because the carrier bearings are worn out. The preload that was originally there is gone from wear. I just re-setup my brother's 70u a few months ago. I can remember a good bit of what I went through. Send me a PM it will be easier to discuss a bit of this on the phone first. GL HTH Hag

-

Treadwright Remold Tires

Mike that is not entirely true. I liked my first set enough to get a second set.... I like them. I wouldn't recommend them without lots of "you gotta knows", and such. Tires can be such a hit and miss and I have no clue what you do with your truck. My friends run them also, and we have had zero troubles* (jamie lost one on a suburbasuarus on a long trip, but I couldn't tell if he hit something in the road, or if it was his constant running under inflatedness.... he is not nearly as anal as I am about tire pressures.) YMMV, but I have never had to add more than 2 oz to balance and have good service out of mine. I don't do a lot of high speed operation. I tow and I tow heavy. Most of my trips are short, but I do tow as much as 200 miles away. On the long hauls I run the speed limit or slightly above or below (depending on load and traffic.) These tires have given me the best compromise of off road performance and on road stability. I am in fields a lot with the tractors. If I only towed highway, I would not have these tires ( I would want a longer lasting street tread) Hag

-

Turn signal is driving me BANANAS!

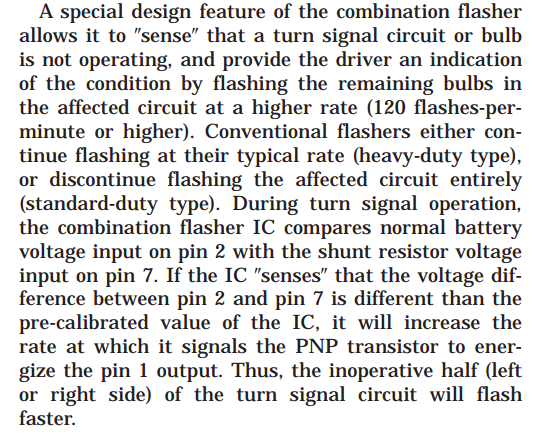

Our flasher unit is special. The integrated circuit can wierd out sometimes. This is from page 8L-8 of the 2001 FSM. When I had this trouble, and no bad wiring I just put a new flasher unit in. That fixed the problem. HTH Hag

-

No boost

Just a thought, (just ran into this on a GM 6.5TD) Wastegate operation.... Motor would not develop any boost. (long story short: turns out the vacuum pump on it died.) I used a hand held vacuum pump and operated it manually during a drive. started getting boost. ( I could not get any/or very little boost on the engine sitting still in the driveway. I guess we just didn't get enough exhaust flow without loading the engine. was fine running down the road.) I know ours works off of manifold pressure, but the components still need to move properly and the wastegate arm needs to seal properly. HTH Hag

-

Intermittent idle surge-increase

-

NV4500 rebuilders

I am pretty sure I got mine from midwest. They bought out all the NV4500s that were slated for GM when NV quit supporting the 4500. So I got a new GM box, with a dodge tail shaft and tail shaft housing. Has worked great so far. The shifter was new, but for a GM, so I had to use my shifter, but no biggie. HTH Hag

-

MoparMan's Hx35/40

GW, All fluids (and many gasses) in motion cause erosion over time. High pressure "fluids" cause erosion faster. So the fact that the diesel is injected at (IIRC the VE is 15,000 PSi) a high pressure, the friction on the walls begins to "tear" "eat" "wear" metal away. This mainly starts at the corners of the restrictive holes, but also begins to wear the holes themselves. (cavitation is the initiator basically.) Just think of the grand canyon. That was low pressure erosion. (just lots of time...) Here is a great description of what injector designers have to go through and look at. He shows the areas he is worried about for erosion at 10:30 or so time. (i think i caught the right start time. If you are interested watch from beginning.)

-

2001 2500 issopro gauge wiring question

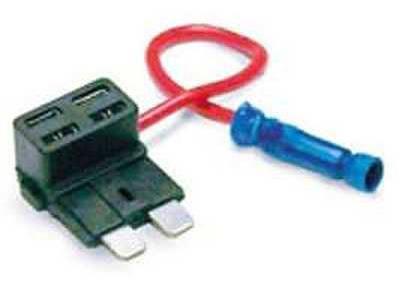

don't splice into existing wires..... just a new headache for later. Use fuse block add a circuit. you can get dimmed voltage on fuse 5 and fuse 14 ( i think) is already called gauges.

-

2001 2500 issopro gauge wiring question

don't splice into existing wires..... just a new headache for later. Use fuse block add a circuit. you can get dimmed voltage on fuse 5 and fuse 14 ( i think) is already called gauges.

-

Snubber differences

Hmmm, I use a tapped banjo bolt at the vp inlet. I have 18" grease gun hose with snubber, coupling, and pressure transducer. I have a nice steady gauge. (too low of a pressure....but that is the lp's fault....). I also bleed that line during assembly. Trapped air can cause weird fluctuations.... It acts like a spring in the system. If you have the old snubber around, see what diameter hole is in it. He may have just gotten a batch with big holes in them. Hag

-

Snubber differences

Those both seem to be "snubbers". But for our application the orifice is too large. The one I use has a 0.004" orifice in it. The sintered metal is a filter to prevent a particle from reaching and blocking the orifice. A lot of places dump all the snubbers in one section and never mention orifice size. McMaster-Carr lists them by orifice size. HTH Hag

-

post brake and wheel bearing job

Green, I am not sure on yours, but my year the 4wd and 2wd have a pre packaged bearing/spindle unit. I am "thinking" on your truck though, you have the "old style" individual tapered rollers. ( that is all I see for the 99 dodge 2wd on rock autos site. the 4wd shows a hub unit.) They work pretty well. I think a lot of the pre packaged stuff came along as anti lock braking became more technologically advanced, and the tone rings and sensors could not stand to be in the weather. I have quite a few vehicles that the bearing units have lived well north of 200,000. In fact I am pretty certain (will have to check records..) but my '99 suburban with 378k is still on its original wheel bearings, though my '94 I replaced them at about 175k. HTH Hag

-

At my freinds tranny shop

Sorry, I'm gonna lose a whole pot of coffee off of this thread alone! Cheers!!

-

At my freinds tranny shop

lol, I lost a cup of coffee. The title of this thread can have a different meaning with a different perspective in today's climate..... A good chuckle in the morning is worth it! Hag