Everything posted by Haggar

-

No start, no turn over, just dead!

Brig, Sorry about that. I must have missed it in the list of stuff you did. Good luck! (I agree, it matters not the codes, it won't start if it won't spin.) Hope you figure it out! Hag

-

No start, no turn over, just dead!

Brig, The contacts in the starter solenoid are a common failure. (relatively) Larry B's has a great replacement. http://www.fostertruck.com/dodge-denso-starter-solenoid-kit-89-2006.html You may want to grab that kit, and take the starter to a good reputable repair shop. (or try the contacts yourself and see if it does the trick.) This would make sure that there is not a further problem in the widings or gear reduction. Hope that helps! Hag

-

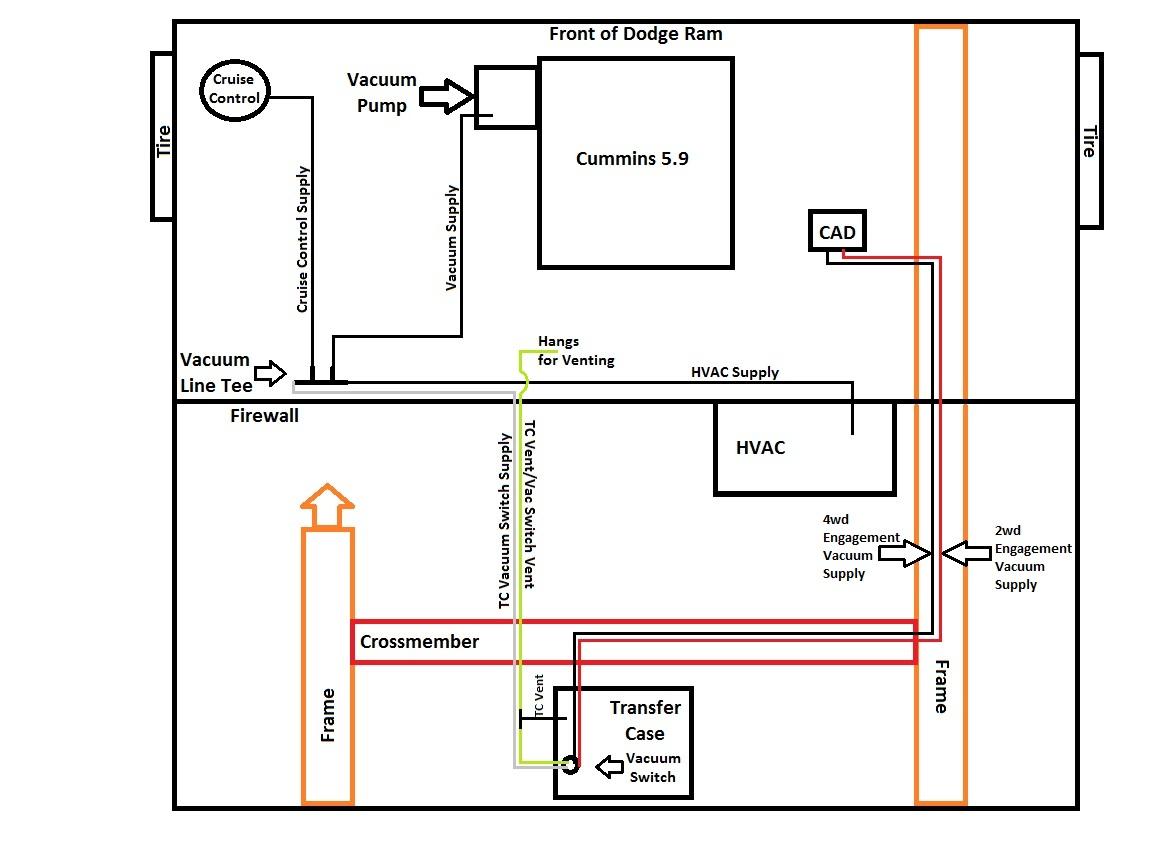

Vacuum test?

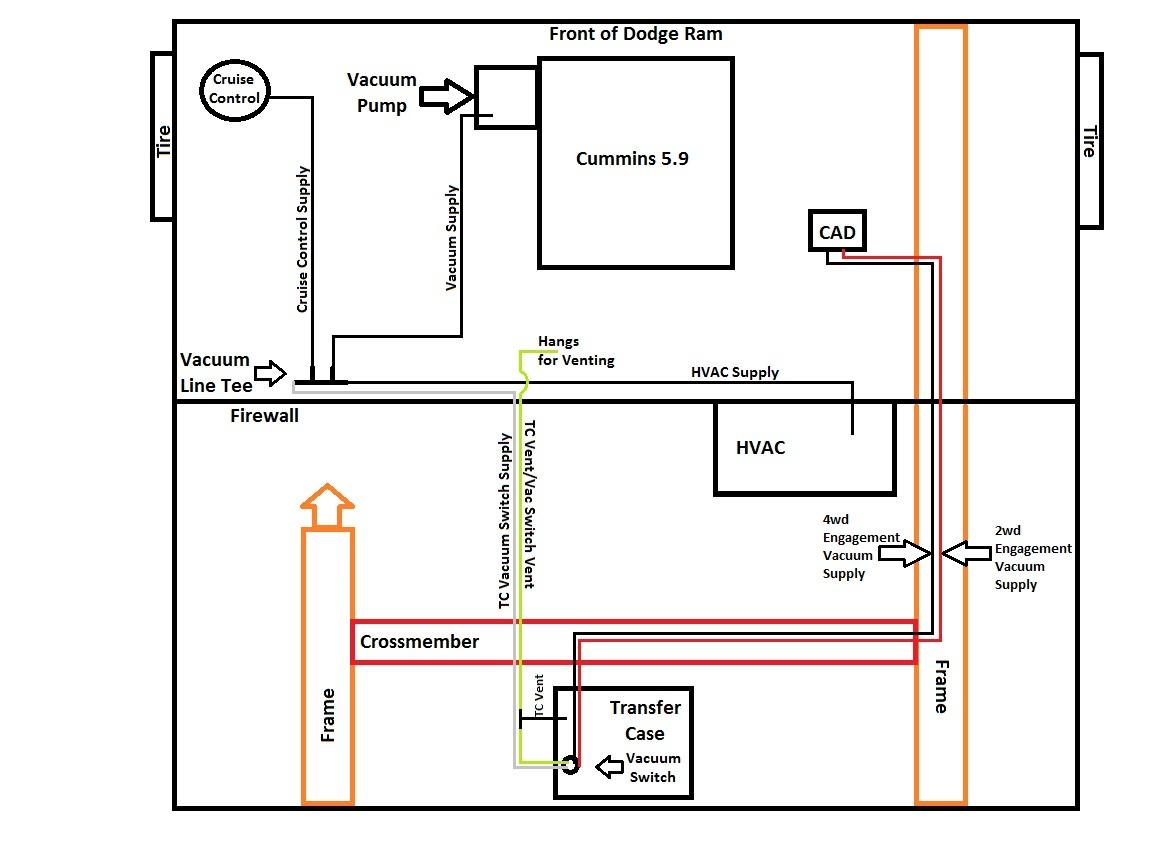

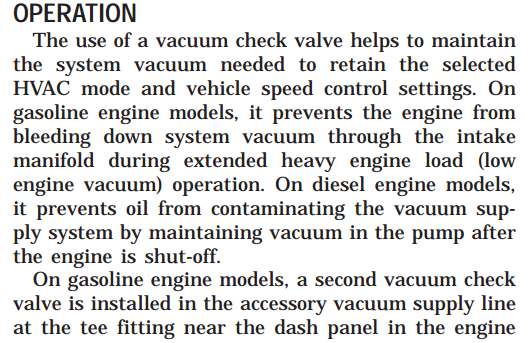

Mike tried to send you a message. they are not going through. H Mike read 24-28 and 24-29 of the 2001 FSM. On Gas models there is a second check valve that separate the HVAC from the cruise Servo. Our system in the FSM shows only the "main" one at the pump. But I agree with you, we have both seen a second check in the dodge system, and that was probably on the cruise servo. We also don't get the vacuum reservoir gassers do. I think the engineers figured that the mechanical vacuum pump was strong enough at all engine speeds to always supply enough vacuum. But since we have seen those check valves, maybe there was a running change help solve some issue, but never made it to the FSM. If I was going to have only one check valve, it would be between manifold and reservoir on a gasser. ( I hate my air conditioning ducts swapping while climbing a hill.)

-

2000 to 2002 Steering upgrade

M, Yes this is true with engine oil, BUT we change it MUCH earlier. The oil dies from combustion byproducts, not "viscosity breakdown". It gets "dirty". Rarely was there a combustion engine (for standard motor vehicles) that had oil temperature problems that were more damaging to the oil faster than the dirt build up. (you could think early air cooled VW flat 4's, some air cooled motorcycles. Some of the newer small turbo or supercharged 4 cylinders may have a tendency to overheat oil.. turbos especially can do that.) You can watch here on the site, there are some guys that have their oil tested to make sure the additives are still there and such and only change it when it is finally "too bad" to repair. I am responsible for some 500 hp gearboxes at work. These gear boxes have never had an "oil change" in 30 years (they hold 200 gallons). but we send off samples quarterly, and based on recommendations, add additive packages into the system, or sometimes remove 30 gallons and add 30 of new. But the heating/cooling system keeps the oil at a constant temperature. Water is one of my biggest problems and am constantly running a portion of the oil through a water separator. Hag

-

Vacuum test?

Mike, On a gas model, everything has to be behind the check valve. (when manifold vacuum goes down, with no check valve, everything will change position as a function of manifold vacuum, not selected position) (if you ever want a fun feeling, hook your gasser cruise control directly to the manifold vacuum source without a check valve.... it will killer slow down uphill, and accelerate like a banshee on the other side of the hill. or just surge like a son of a gun) Notice in the FSM description for diesels..... The check valve prevents oil from being pulled up the vacuum line at shut off. (since our vacuum source is relatively constant, not manifold pressure dependent.) So it really doesn't matter where the check valve is. Thinking through this.... I see why we have "blowby" issues with a vacuum leak..... The vacuum pump normally reduces pressure in a very small known volume. Lets say a gallon of volume. So when we start the truck this volume is removed. It stays constant unless we actuate something. when we actuate, its a pint to a quart in volume at most..... What is a vacuum pump? simply Its a "fan" that can create negative pressure. We know where the air comes from (the gallon or so in the actuators) Where does the air go? it goes right into the crank case..... (there is no "exhaust" port on the vacuum pump.....it would sling out oil due to the wet vane design of the pump....) So when we have a vacuum leak, we have a "fan" taking in outside air and pumping it directly into the crankcase ventilation system. (sorry if you guys already knew that. It finally occurred to me why the vent system went wonky.) Hag

-

2000 to 2002 Steering upgrade

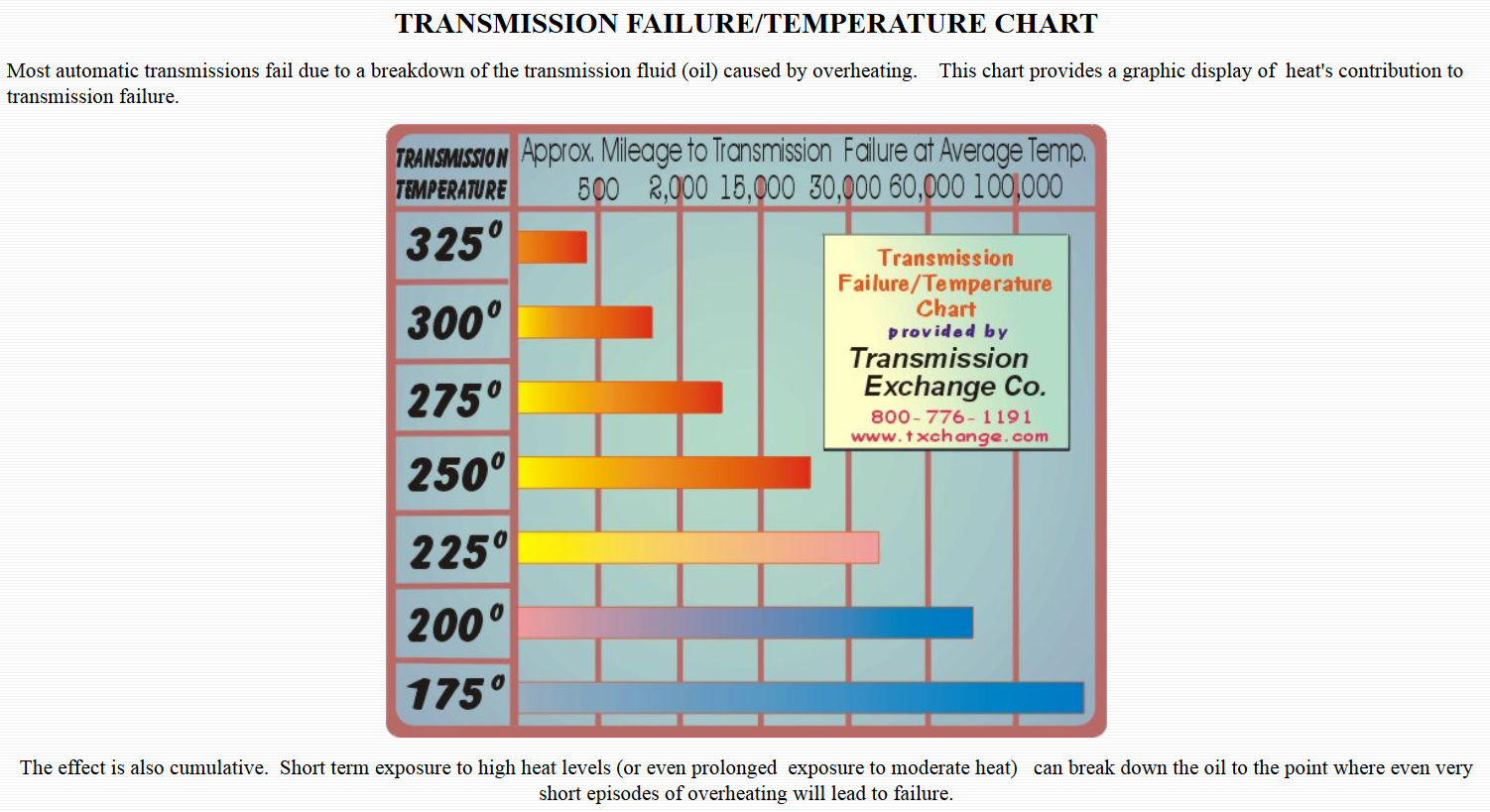

Yep. That is probably the biggest killer of closed system hydraulic/gear fluids. (transmissions, differentials transfer case power steering.) The high temperatures break the molecular chains in the fluids. The higher the temperature the faster the degredation. Here is a quick chart. Not far off of reality. This is pretty much the same for most hydraulic oils (the oils in our differentials, are a bit better but they are much higher initial viscosity.)

-

Code problems p0238 p0112 p0521

FSM page 14-103. It will vary voltage in relation to manifold pressure. Seems a bit odd that it reads 3.4v on low end. A couple other guys will chime in with decent ranges for the voltage versus manifold pressure. HTH Hag

-

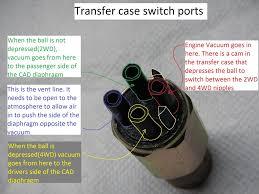

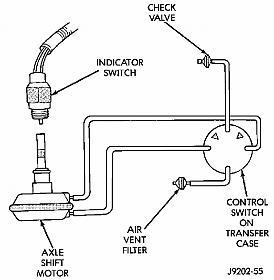

Vacuum test?

Quote from 2001 FSM Page 24-29 the check valve is not shown in the picture I attached at the end, but basically, the check valve goes in the "vacuum supply" line. This means that when you turn off the vehicle, and the vacuum pump quits rotating, all of the components further down the system stay in the proper vacuum positions. In gas engines it is very important, as when you open the throttle, manifold vacuum goes down. So during acceleration, all the actuators would change position. IF there was no check valve, in our trucks when the engine was stopped, the vane type vacuum pump will allow all the vacuum to escape backwards through the system, so all of your actuators would relax and move while the truck is off. It is by no means a killer problem if the check valve is broken (as long as it allows the vacuum to operate properly when the truck is running.) Just don't put it in backwards.... you won't have any function of what you need. another interesting picture.... this shows(or leads one to believe) that the valve is built into our vacuum pumps. Hth Hag

-

Gear Selector on 96 is stiff and can hardly move?

AWESOME!!!!! Glad you found it!!! And glad it wasn't the bushings.... those can be hard to find. (and usually other stuff is worn out when those are gone...) Hag

-

Power steering prob

Kbraun, Here is a picture of how the drive coupling pairs on the vacuum pump. The male "teeth" on Item 1 must go into the recesses on the drive coupling of the vacuum pump Item 3. It is possible that this is not working properly. The new pump could also be bad is another possibility. Trucks that are in accidents frequently break the drive coupling on the vacuum pump. Good luck! Hag 2001 FSM RAM 19-35.pdf

-

Gear Selector on 96 is stiff and can hardly move?

This is a typical drawing of your selector assembly. (this is NOT yours, couldnt find it in the manual, but most everyone's is similar) Start with where it shows the grommet and front assembly rod. This is near your firewall under the master cylinder. I would disconnect this rod, and test your column selector, if it is easy to move, the problem is in the rest of the system. If that is tough spray lube up the column hoping to free it up. The bushings on the torque shaft can go wonky on you too, causing a lot of drag. GL HTH Hag

-

The crf450ish random question thread.

From my experience, Moog is not what it used to be. YMMV. During your inspection, remember one of our ball joints is more like a king pin. It can have some vertical movement (no radial movement) and not be bad. (I think it is the lower, but I don't remember.) Good luck! Hag

-

Help ID-ing these parts?

PH, wow, this seems tough. Having trouble on the webz finding out how. Some say remove the pattern insert and there is a nut under it.... Notice on this page "Chrysler full size...." Dakota shown.... but it shows a nut under the insert. https://www.autozone.com/repairguides/Chrysler-Full-Size-Trucks-1997-2000-Repair-Guide/TRANSFER-CASE/Shift-Linkage/_/P-0996b43f80394f99 This replacement shows that the patter insert pops out. might be it! https://www.ebay.com/p/CHRYSLER-OEM-Transmission-Gear-Shift-Shifter-knob-Handle-52104174/1222206732?iid=401014190170&_trkparms=aid%3D222007%26algo%3DSIM.MBE%26ao%3D2%26asc%3D47300%26meid%3D19faaa6ad20c4f5f91a4cef3c20fd465%26pid%3D100005%26rk%3D1%26rkt%3D6%26sd%3D161941074842%26itm%3D401014190170&_trksid=p2047675.c100005.m1851 HTH Hag

-

Wait to start

Here is the FSM page. If there is anything wrong, you may have trouble with the IAT sensor, or the ECM seeing this sensor. Is it "staying on" all the time, or just the time that it is supposed to be on? For me it depends on temps and what I am doing with the truck, but I can do some short trips in cold weather, and it will feel the need to cycle the grids on next start up. Hag 2001 FSM Ram 8J-35 wait to start.pdf

-

Help ID-ing these parts?

PH, It should unscrew. Look closely at the lower edge for a small set screw though. (I can't remember exactly how I got mine off. but it is something like that.) HTH Hag.

-

Wait to start

The wait to start should come on with each new "key on" instruction. It will go out quickly if the intake temperature is above a certain point. If it is below that point, it will stay on until the grids fully cycle. HTH Hag

-

High amp alternator

Mike, I don't think purely resistive loads "wear out". They are either open (broken) or shorted. They can lose their efficiency (ability for heat transfer) , but this comes more from contaminants on the outside of the elements. (think of an electric water heater... mineral deposits on the outside of the elements. so a hot water heater has to run longer to bring the same amount of water to a temperature) (it is interesting, I will try and talk with an electrical engineer buddy, but could it begin to develop inductance over time, therefore not behaving purely resistive....) Anyway, I think the place for "load" to "change" in this system, would be the contacts in the grid heater relays themselves. I can envision that the contacts become poorer and poorer over time (increasing the impedance (resistance)) causing the "grid heaters" to pull more amperage than normal. IT is very tough to measure high DC amps easily. (though some of the new clamp on claim to measure DC current, I have yet to play with one to see.) I just had a grid heater relay failure, so I hope to update you guys with some pictures and better testing soon. Hag

-

Hydroboost overhaul

DF, Here is who I get my kits from. I have had great service from them. http://piratejack.net/hydro-boost-rebuild-kits/ I usually get the 45 kit (but that was the only thing they had last time I ordered.) it looks like the seals only will work for you, if your metal parts are not rusty. (on most that I have done, it looks like the kit would have worked for me.) GL HTH Hag

-

Plugs , back up light switch

Wow, For some reason there is not much info on the flat connector. (I guess they only used it a couple years.) Chrysler didn't put info in the FSM on exactly what connector. They used a round connector for years on the same switch. Lots of info on that. But not much on the newer flat one. For the male end, when you figure out the series of the female you may be able to find the compatible male. (it may have never been made though.) Good Luck! Hag

-

Low system voltage

Remember, on our trucks, voltage regulation is NOT in the alternator. It is located in the PCM. The PCM does all of the voltage regulation. If you have some time the 8F section of the manual helps understand it a bit. HTH Hag 2001 FSM Ram 8F-31.pdf

-

Possible ground and tq problems

Was the alternator in your hand or still on the truck for the alternator test? If still on the truck, it would not be a ground problem. Something was drawing current. .... freaking gas car all the same diagnostic equipment ... your truck has "accessories" most never think of. Fuel heater, grid heaters.... These would look like "accessories" to a stupid diagnostic device, but be normal in diesel trucks.... (you could pull the fuse for the fuel heater and the main wires off the PDC that feed the grids.) You might get a better diagnosis of the alternator by taking it off the vehicle. Less confusion. Just make sure they are actually check for AC voltage. Most of the standard "alternator checkers" don't even consider AC as a potential problem. HTH Hag

-

4x4 won’t work! Help

-

Back up light switch plug wires

GSP7, Hope it is not too late... I posted in the other one, your question on where to pick it up. It should be in your 7 pin trailer connector plug already. You could go right before the connector and splice into the violet/black right there. HTH Hag

-

Light Bar Battery Source

This is from my '01 FSM, so wire color may be wrong, but there should be a factory wire already at the rear for backup lights. In this schematic, it is the violet black (vt/bk) wire. This goes into the factory seven pin trailer connection. HTH, Hag 2001 FSM Ram 8W-54-3.pdf

-

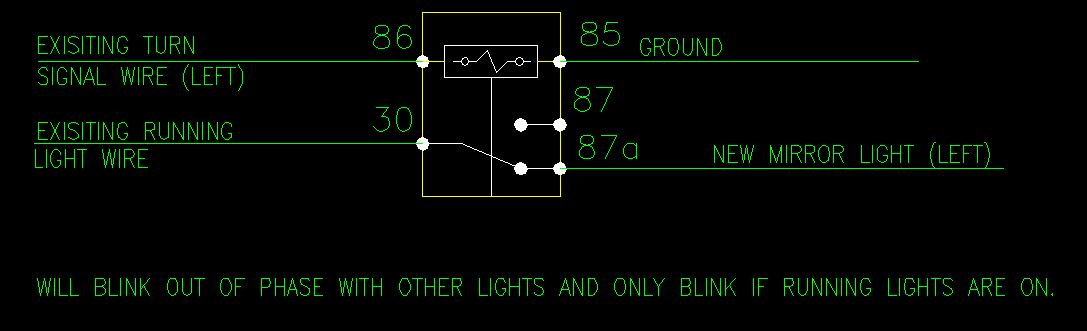

Door wiring for lighted mirrors

Nuke, The only problem I see with this once the running lights are energized, the turn signal will not make it flash. It might "brighten" a tad due to the dual sourcing of 12v input, but nothing kills the constant power from the running lights. You could do something like this with one relay per side. To get all you want will take a bit of thinking.... hmmmmm, Sorry not as much help as I thought I was... This is kicking my butt.... Two relays per side isn't working properly in my mind.... its getting expensive.... Merry Christmas though! I will keep thinking.... Hag Next unread topic Miss When Warmed Up