Everything posted by Haggar

-

Only have turn signals and hazards.

Hit, No bus means there is no communications between the computers (PCM, ECM and cluster) you will need to troubleshoot that system. It could be as easily as the cluster not communicating, but that usually doesn't limit engine ( you can drive with no cluster installed) since you are losing power it sounds like PCM ECM communication issues. GL Hag

-

No Change in AC Readings (Post Ground Wire Mod)

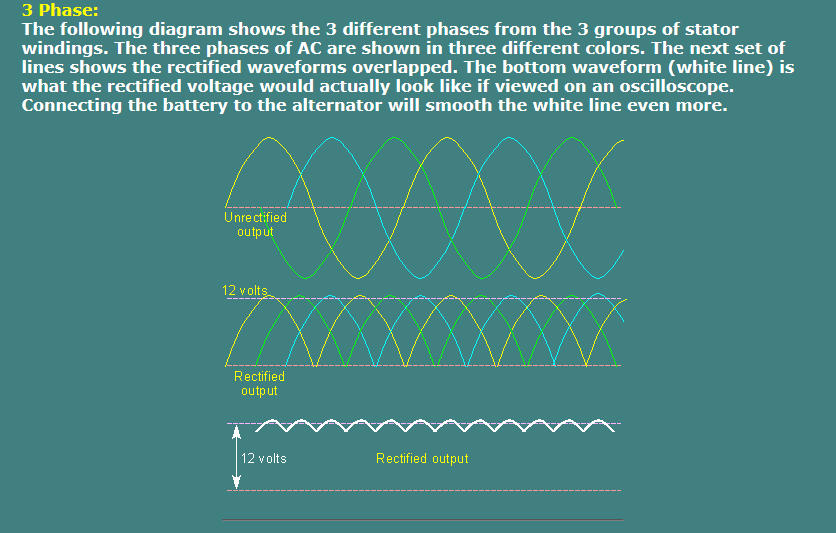

Soox, I think you need to test the alternator again. It is where the AC noise is generated. The alternator makes AC power. The diode bridge (rectifier) is designed to take that AC waveform in, and produce as close to a DC wave form out as it possibly can. Nice simple explanation at basic car audio electronics ( http://www.bcae1.com/charging.htm ) Here is a picture of what is happening: Notice the rectified output is still wavy. that is "AC noise". that is what you are seeing. Those waves in the output get bigger the harder the alternator has to work. While the diodes are a big part of the AC, there are still the brushes (commutator) also. Take your alt to an alternator shop. Tell and pay them to test it, BUT be there. Ask them to perform the AC test under load. He may look at you funny (it is not a normal test) explain that the Chrysler (Diamler-Chrysler) electronics are susceptible to AC noise and cause other problems sometimes. He may have dealt with it enough to understand or he may not completely believe you. (mine didn't... but it was cool when he called his automatic transmission buddy and asked and that guy said it could really be a thing.) Anyway, this should help him understand what you are searching for, and he can rebuild it looking for what is causing the high AC. Take your meter with you, if he gets a different reading, use your meter. if they differ, find a third meter to confirm. HTH Hag

-

Surging I think

Colt It sounds like you are locking/unlocking the TC. The indicated speed you mention is exactly where it will happen. This is usually an AC noise issue or a grounding issue. Edit: I re-read your post and the last sentence may throw that idea out the window, but odd it happens or started happening in that speed range. I just got my first automatic 2nd gen. I am noticing this at certain times too, and will be hunting for the cause. GL Hag

-

Turn radius and steering stop modification

X, That is an interesting question. I will try and get an idea of that. I just bought a 99 1 ton (its 4wd though). Have not driven it much. My brother's 2wd is in Atl. but we can talk about it. So far the 1 ton seems a lot like my 4wd. I am having more trouble with the wide hips than turning at the moment, but I will be moving some trailers soon, and that will tell me more... Hag

-

AC Replacement

Leaky, Just a bit on 4 seasons. I like them. They make a lot of products for AC and engine cooling systems. They seem to have a pretty decent R&D dept. They are not perfect, I have had some bad things from them. But when given choices, I will tend to use 4 seasons stuff and never worry about it. I find that most of their products are as good as OEM, or in some cases designed to help/overcome a flaw in the OEM part. Just my $0.02 Hag

-

Turn radius and steering stop modification

X, There should be no problem with that. It will depend totally on what wheel offset you are running and what size tires. On my brother's truck we had to watch full left lock and then compression. He touched somewhere, so we actually had to add to his stop. but it is because of huge tires at the moment. What I am saying I guess is trim and watch, but not just statically, you need to watch during suspension extension/compression also. GL Hag

-

Erratic miss at idle

You didn't mention if you had checked your valve lash lately. If you have not, you might be surprised. re-adjusting mine made a huge difference. (they were wayyyy out) GL Hag

-

brake main line failure

Glad you got it! Hag

-

Only have turn signals and hazards.

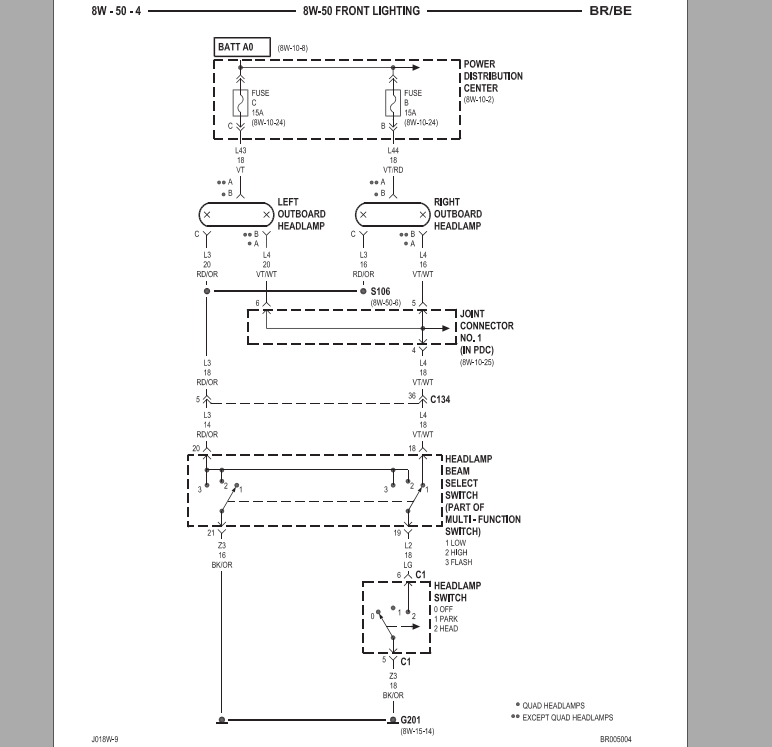

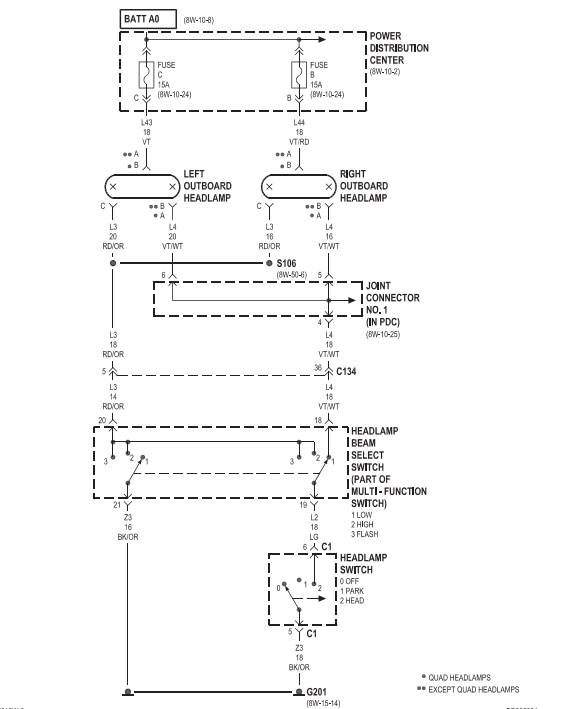

Hit, The multi-function switch can be a problem, but you should still get low beam headlights without it. We have a great selection of .pdf manuals here. Look at the top tabs. There is "forums", " articles" , "downloads" Click the download section, then look at the list and pick "dodge ram factory service manuals" Pick your years and save them. Section 8w is the electrical section. That will be your best friend. I think the first thing to figure out. Is your dash a push pull headlamp switch or twist knob? were any of the iterations push pull headlamp? On the turn signals, if they did work and now not, it is probably the flasher unit. Our flasher unit is not the old heater type, but an electronic timer thingy. It is VERY susceptible to damage from funny voltages. It will do things like fail leaving one turn signal on all the time. So at the moment, keep searching for the main problem. Hag

-

brake main line failure

Sorry, I didn't catch that you had new drums. The curves should be close then. Well, stay on top of adjustment. The "automatic" adjusters work sometimes... that is the best that I can say. They only work in reverse btw. So if you can, find a flat empty parking lot and do a lot of backing and abrupt stops. only other thing I can think of is, do both parking brakes grab simultaneously? If one is way ahead of the other, you will get a firm park brake pedal, but only getting one side trying to hold. Good luck! You have it so close! Hag

-

Only have turn signals and hazards.

Hit, You should not have grounds to the headlamps unless the headlamp switch is in the ON position. the headlamps have constant 12v+ from fuses B and C in the PDC. (this is from the 2001 FSM) GL HTH Hag

-

brake main line failure

Like Wil said. Did you happen to check the curvature of the shoes to the drums? I always take my shoes and test fit them in the drums. You will almost always see that either the middle hits first (so you spread the shoes out some) or the ends hit first (so you squeeze them closed a bit). What you are looking for is the complete surface of the shoe to contact the drum simultaneously. There is a primary shoe (short) and secondary (long) the primary goes toward the front of the vehicle. Did you have the drums turned or was there a wear lip? I have had instances where the wear lip contacted the shoes, so you get some dragging, so you think the adjustment is correct, but the surface is really small (until it beds in). It might be worth a peek at one side to see if you see something odd in the wear pattern. GL HTH Hag

-

NV4500 downshift Problem...

DWB, You may want to pop the tranny out and see what is going on. Mike (moparman) had made a good point on the pilot bearing... If that is damaged or dragging, similar issues will happen. No I think the 13" is a good replacement. Where we usually start seeing inertia problems is on the dual disc setups. That has a significantly different inertia load. I am spooked by you saying it is noisy in 4th gear. Fourth should be the quietest gear. power is direct from input shaft to tail shaft. that is the least amount of gears and bearings in operation. The NV4500 is not as complicated (apparently) as the NV5600 is. (as far as special tools go.) I just did a quick check and kits seem to be pretty available and there are a couple videos out. It seems straight forward. GL HTH Hag

-

Coil spring removal

I have a floor centerpost lift. I left the wheels on the ground and lifted the frame up. If you have tall jack stands, just disconnect the shock and the swaybar end links with tires on the ground. Start lifting the frame up with a jack, at a certain point the springs will be loose. Use your jackstands to hold the frame in that position or higher. From your existing frame height, you will need to go up about 12 to 18 inches, so you may need to use some blocks under your jack stands. To get the front axle the rest of the way out: drive shaft, control arms, Cad wiring and tubing, brake lines, ABS wires, Axle vent, track bar and pitman arm. I think that is it. GL HTH Hag

-

Tire balance

DF, The studs don't hold the vertical wheel load up in shear.... You are ok if you can still torque them properly. It will take a minute for some people to wrap your head around this concept. The lugs hold the rim to the hub. When the torque is correct, the vertical load of the wheel is not held by the lugs(in the vertical sense), but the load is supported by the shear created by the surface of the rim held tightly against the hub face (or the rotor if you have hats etc). When you design a bolted connection, you design that the bolts don't see a shear load, they will fail. You design for a compressive load over an area to resist the shear load. I hope that makes sense... I can pull some drawings if you need it. HTH Hag

-

Drivers headlamp very dim

Great Job! Glad you found it!!! Hag

-

Intermittent no start, 8 volts on ground wires,

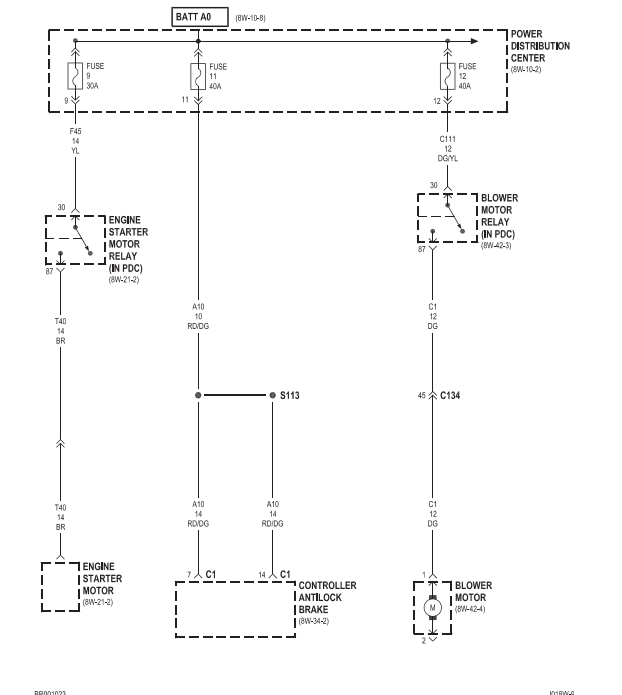

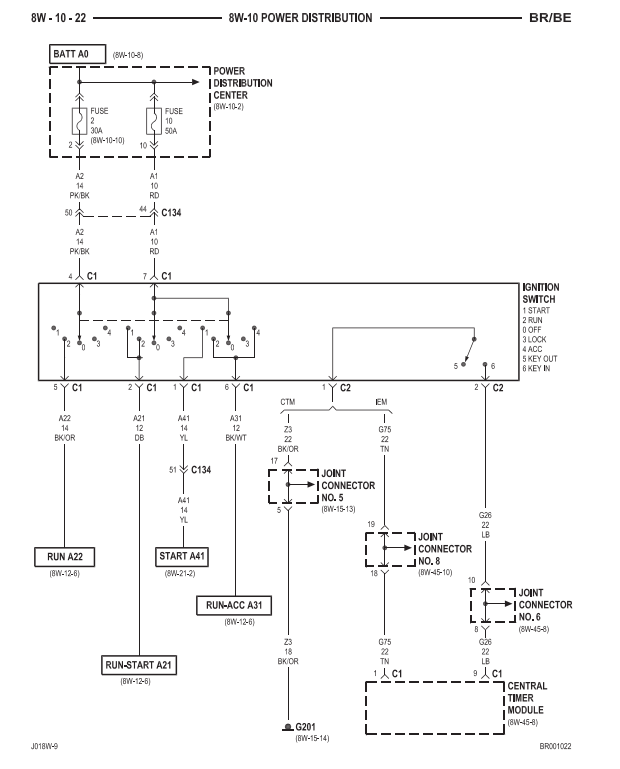

Not sure what year yours is. From my 2001 manual (my manual says 40 amp): It is the power for the ABS controller. My fuse 10 is 50 amp and goes to the ignition switch. HTH Hag

-

Dim left headlight

Loki, You should start a new thread.... BUT the ground for the headlights is G201. (this is a 2001 manual but yours is probably similar. The headlamps are sent constant 12v (even with key off.) the headlamp switch and multifunction switch allow the bulb to "see" ground to come on. For there to be a difference on the ground side it has to be the splice S106. To set up a test of whether it is the ground or the hot side, use a different headlight bulb from another car with a socket. (I have cut a couple of these from junk cars.) put some long leads on it. Connect one lead from the test bulb to the battery positive, and connect the other lead from the test bulb to the suspected socket ground. If it lights bright, ground is good and positive is suspect. If it is dim ground is suspect. Then reverse the test light bulb. One lead on battery negative, the other lead in the suspect socket positive. Another thing that can weird out the headlamps.... did someone swap a 9004 bulb for a 9007? I don't remember which one is correct, but the socket is exactly the same but the filaments are connected to different pins. (if you don't get it, swap the bulb from your right headlamp to your left, did the dim bulb follow the move?) GL HTH Hag

-

Replace Rear Axle Seal

Chrysler ordered the axle from dana/spicer, but did their own engineering for the spindles bearings etc. When you follow the bill of materials for the rear ends through dana, you come to a picture that shows squares where the spindle should be and is says something like "provided by customer". I was hoping to see the drawings for the spindles and bearing arrangements to compare the drw 80s vs the single rear wheel 80s. (to see if there was a hub to use a srw on a dually rear without a lot of fuss....) Looking through the parts manual the single rear wheel 80's share the same seal, inner bearing and inner bearing race with the 70, but the outer bearings locknut and such are shared with all 3/4 ton and 1 ton applications... While looking in the parts manual. the 70 is should be on the glove box list as DRE, and it was only on lines 2 and 7 (2500 2wd and 4wd respectively) The 80 is DRL and was offered on lines 2,3,7, and 8. (2500/3500 2wd and 2500/3500 4wd) The Chrysler part numbers for the axle shafts are different for the 70 (04856290) 80 srw (04746995) and the 80 drw (04746967) HTH Hag

-

NV4500 downshift Problem...

DWB, Welcome to the forum! If you went from the stock 12 1/4" to 13" you increased the rotating mass of the clutch. (would be neat to know the weight differences to calculate the moment of inertia) But if you think about it, the synchros provide the energy necessary to change the speed of the input shaft (up or down) to allow the gears to mesh properly. You have changed the moment of inertia of this input shaft. So the timing is going to be a bit different. (you have added more load.) You may need to work on speed matching a bit better. You are asking older synchros to do more work now. Have a great day! Hag

-

Intermittent no start, 8 volts on ground wires,

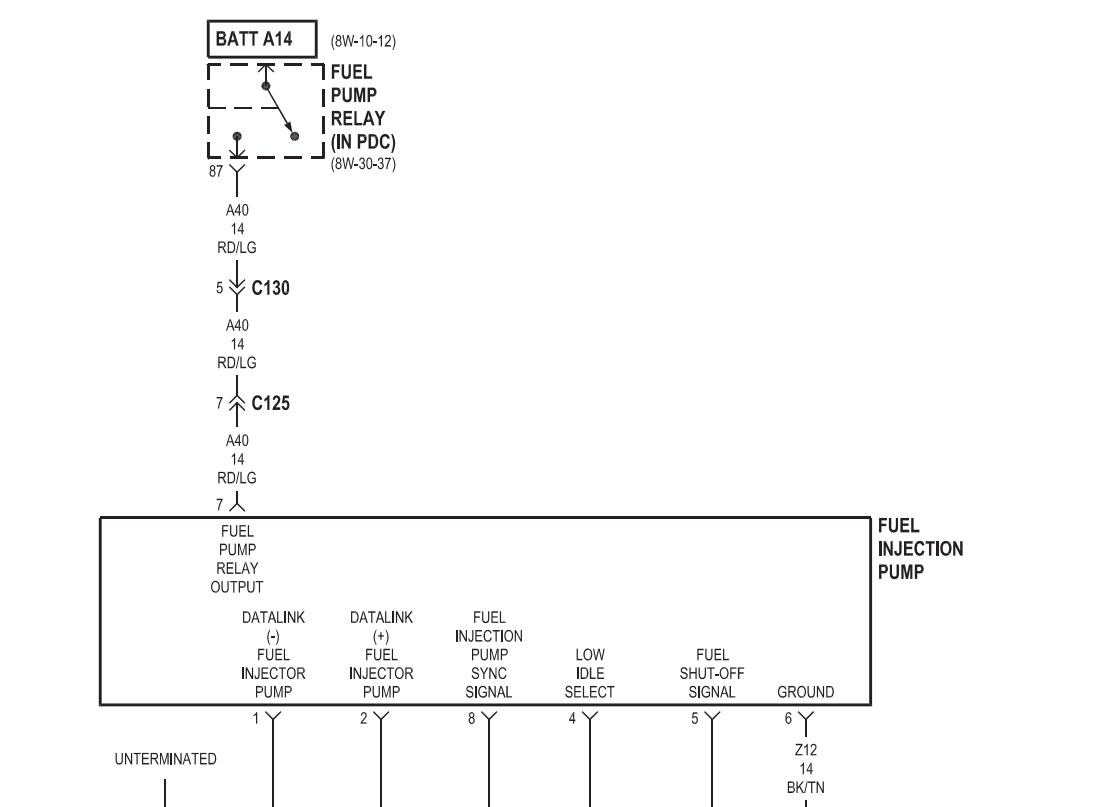

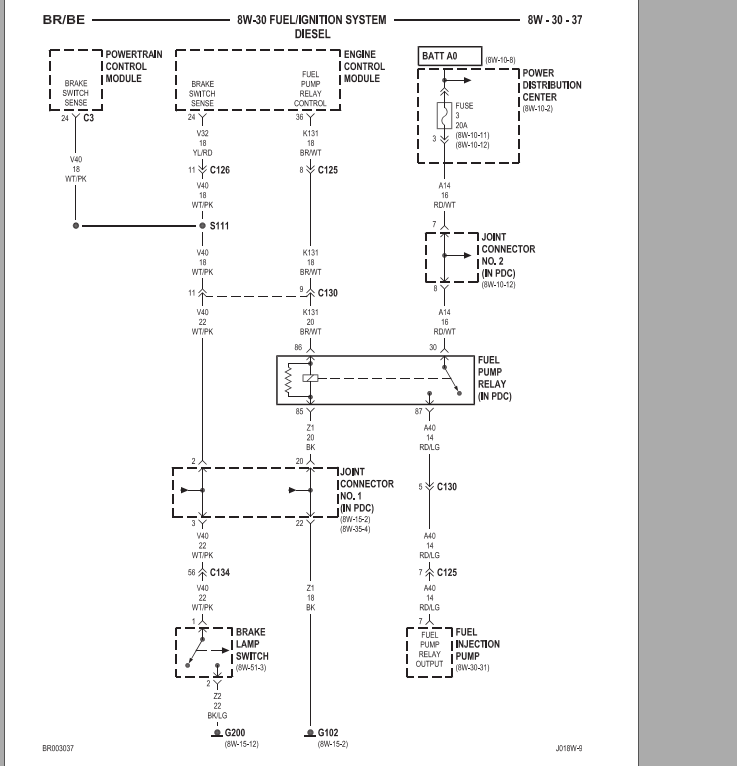

fuse 11 in the PDC is for the anti-lock brake controller. Here is pin 7 at VP. It is the communication from the pump relay. Your electrical problem is not allowing this relay to reset properly. (first picture) Second picture is how the relay is triggered. This is from a 2001 manual. your mileage may vary.

-

alternator questions

AC voltage doesn't immediately kill it. so you could wait. Or take the alternator to have it checked. Rebuild shops don't normally check for AC but ask them to do it. If you return the fuel to the jug you can run a long time on a couple gallons. If you run from the jug but return to the tank it will disappear quickly. I drove less than 3 miles on 5 gallons on a jug as supply, but return still connected to tank. (the return flow is significant) GL HTH Hag

-

Heater core or something else?

don't do a sealer.... If the leak gets bad enough take the heater out of the coolant circuit. Just take the hose going TO the heater, and connect it directly to the hose going FROM the heater. This will bypass the heater core. There are times ane places for sealers.... (Miracles in a Can) but avoid it if you can.... that goo goes EVERYWHERE in the system, it doesn't just target your leak... HTH Hag

-

Heater core or something else?

What is your humidity like at the moment. (and cold/hot the ambient temp and heater temp) It could be as simple as how you are passing through the dew point. When mine went, I did not get the coolant smell much, but I did have the residue. I would watch and wait. Hag

-

Heater core or something else?

it sure sounds like a heater core. (are you losing coolant?) You could try bypassing the heater core and see if you still have the same symptoms. You could also try a cold pressure test. "rent" the tool from one of the box stores. I love mine.. makes troubleshooting much easier. I know it can still be cold your way.... but you could bypass it for awhile for summer. GL HTH Hag